A method for evaluating the durability of snow melting effect of snow melting asphalt mixture

A technology of asphalt mixture and evaluation method, which is applied in the direction of analysis materials, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as only suitable for analysis, poor simulation, unsuitable for experimental research stage, etc., and achieve simple and easy test execution, shorten the test time, and facilitate the evaluation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

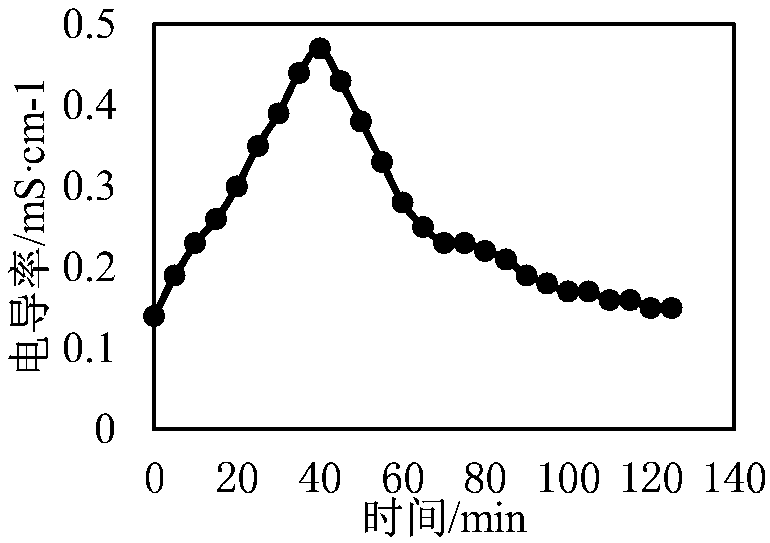

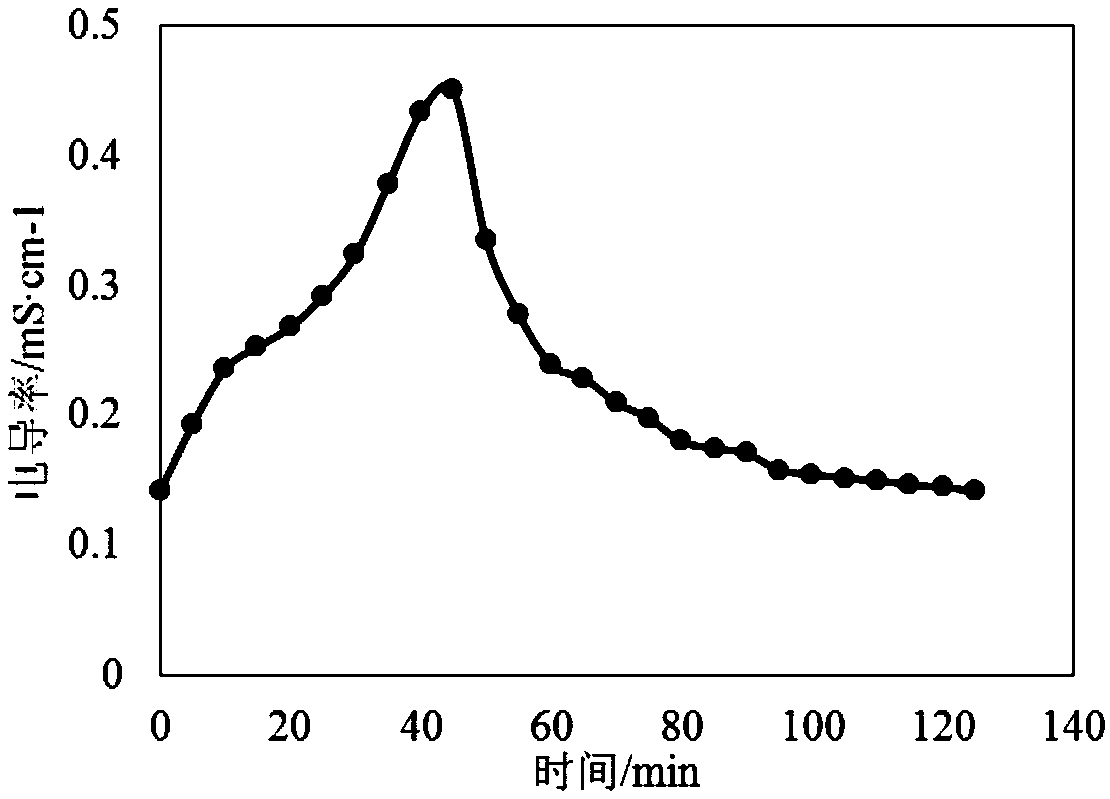

[0034] The assay method of the present invention has obtained good experimental verification. The snow-melting durability of the snow-melting asphalt mixture was evaluated by the method of the present invention.

[0035] The instruments and materials needed for this embodiment include:

[0036] (1) The rutting plate specimen formed according to the method in "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering JTG E20-2011" T0703-2011; (2) The head used for sprinkling water; (3) The measuring cylinder with a measuring range of 200mL ; (4) timer, accurate to the second; (5) glass; (6) conductivity meter, which can measure the conductivity of the solution within the range of 0-100 ℃, accurate to 0.001mS / cm.

[0037] According to the method in "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering JTG E20-2011" T0703-2011, the rutting plate specimens are formed. The length of the rutting plate specimens is 300mm and the width is 300mm; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com