Strip structure-based electric control terahertz wave switch

A strip and electronic control technology, applied in the field of terahertz wave switches, can solve the problems of high processing technology and processing environment requirements, complex structure, high cost, and achieve the effect of simple design principle, simple and compact structure, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

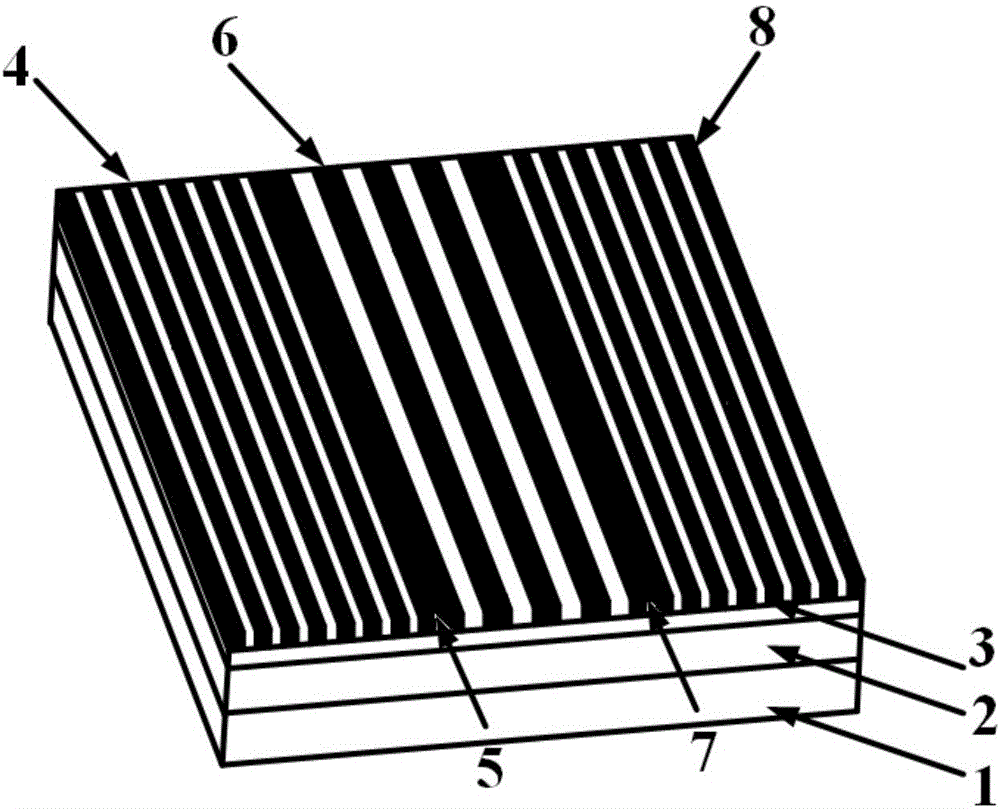

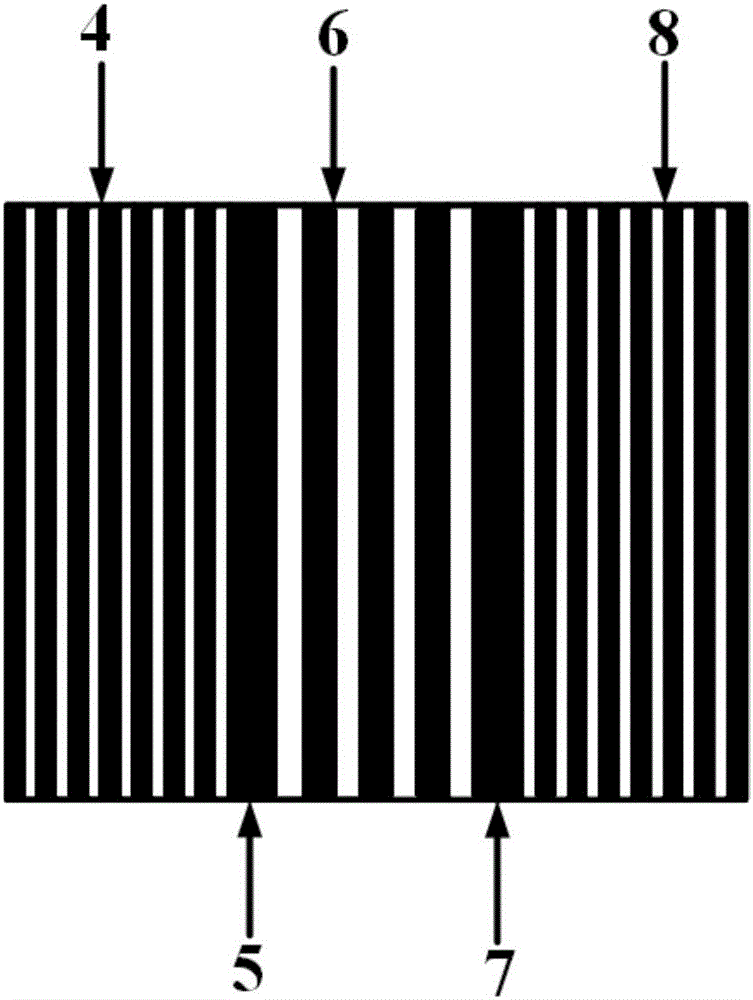

[0016] Such as Figure 1~2 As shown, the electronically controlled terahertz wave switch based on the strip structure includes a base layer 1, a silicon dioxide layer 2, a molybdenum disulfide film 3, a first strip region 4, a left rectangular strip 5, a second strip region 6, Right rectangular strip 7, the third strip area 8; the upper layer of the base layer 1 is a silicon dioxide layer 2, and the upper layer of the silicon dioxide layer 2 is covered with a molybdenum disulfide film 3, and the molybdenum disulfide film 3 is provided with a first Stripe area 4, left rectangle strip 5, second strip area 6, right rectangle strip 7, third strip area 8, first strip area 4, left rectangle strip 5, second strip area 6 , the right rectangular strip 7, and the third strip region 8 are arranged in sequence from left to right, and the terahertz signal is vertically incident from directly above the second strip region 6, passing through the molybdenum disulfide film 3, the silicon dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com