Female terminal of electric connector and processing method of female terminal

A technology for electrical connectors and processing methods, applied in the field of electrical connector female terminals and their processing, can solve the problems of difficult adjustment, small contact area, re-opening molds, etc., and achieve reduced contact resistance, high current-carrying capacity, plug-in and pull-out Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

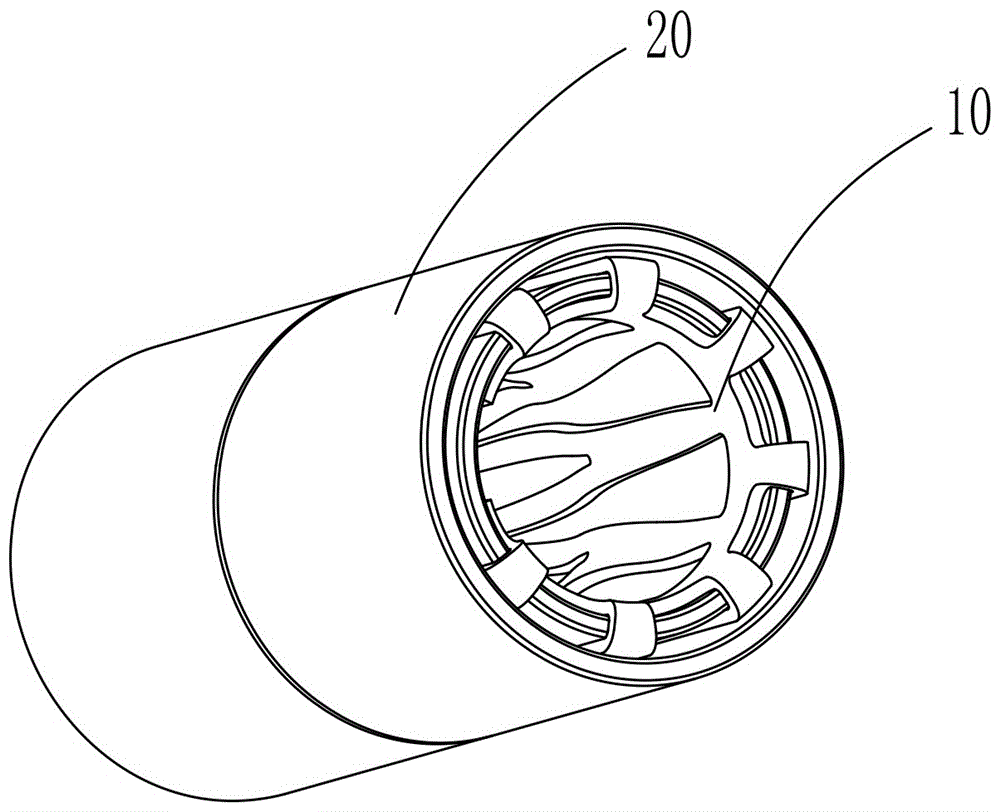

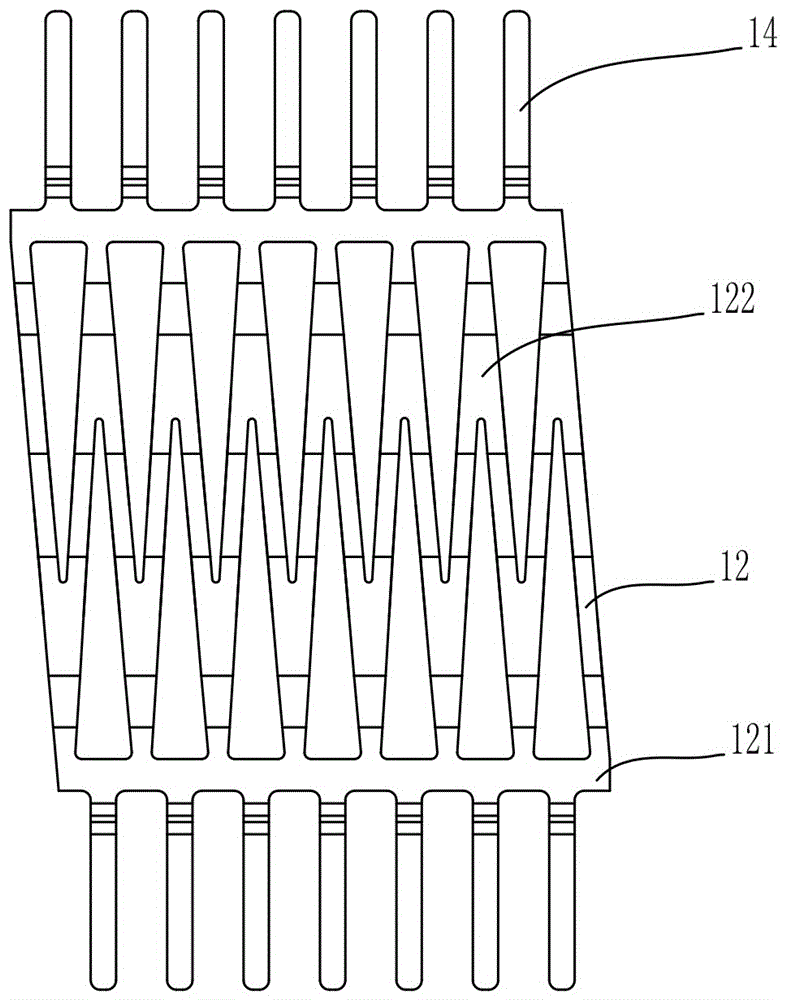

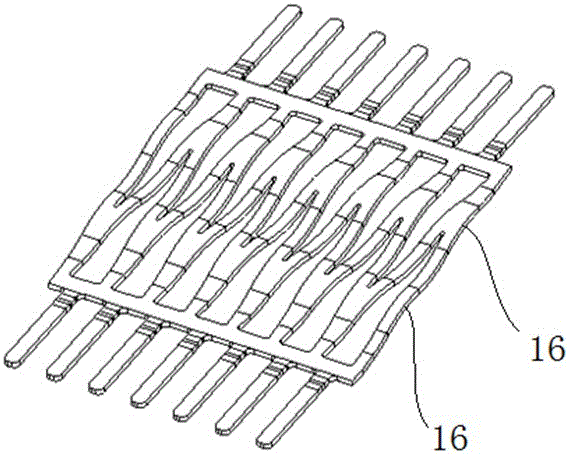

[0029] refer to Figure 1-8 , The present invention includes a cylindrical body 10 made of conductive material, an inner liner 18 and an outer sleeve 20 . The main body 10 includes a first end 101 , a second end 102 and a contact portion 12 , the first end 101 and the second end 102 are elongated fixing claws 14 .

[0030] In the embodiment of the present invention, the contact portion 12 is a cylinder formed by rolling a non-rectangular or square parallelogram. When the female terminal of the electrical connector of the present invention is inserted into the corresponding male terminal, the edge of the contact part 12 has an inclined angle, which generates multiple component forces in the radial direction, making the shape of the female terminal of the electrical connector more compact. Reliable, small deformation, longer plug life.

[0031] The contact portion 12 includes at least two annular curved surfaces 16 protruding into the cavity surrounded by the contact portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com