Drive unit for electric bicycles

A technology of electric bicycles and drive units, which is applied in the direction of rider drive, vehicle components, vehicle gearboxes, etc., to achieve the effect of maintenance-free and light maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

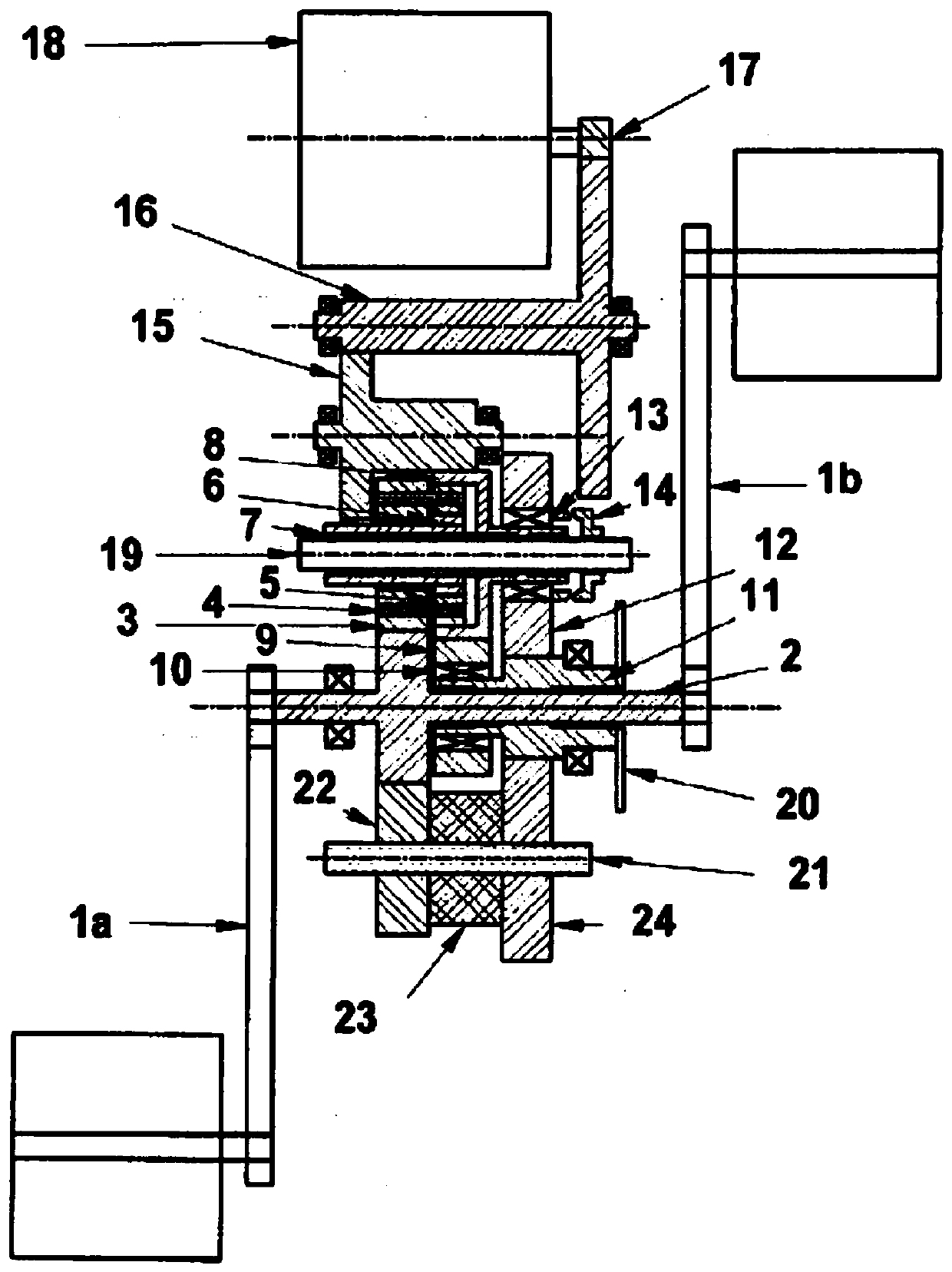

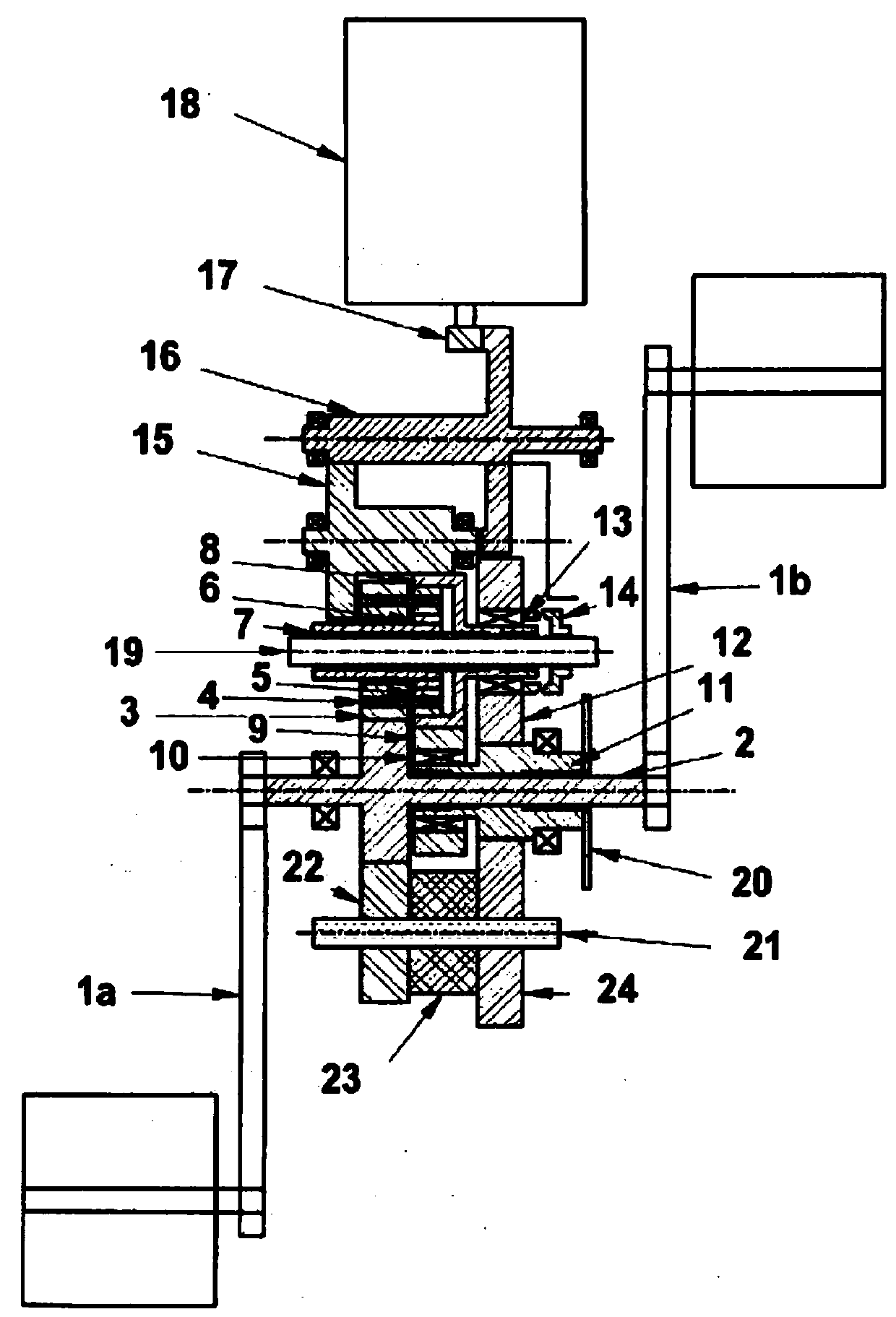

[0023] In these embodiments, a 2-gear speed reducer is used. For simplicity, all components in the figure are shown in plan view.

[0024] The pedal force of the drive unit is transmitted via the crank arms 1a and 1b to the crankshaft 2 mounted in the housing. A spur gear integrated into the crankshaft drives the planetary carrier 3 with spur gear toothing of the planetary gears mounted on the shaft 19 . The planet carrier 3 and the planet gears 5 are connected by means of the shaft 4 in order to transmit the force to the ring gear 8 .

[0025] The output drive is realized through the hollow gear 8 . The sun gear 6 is connected to the sleeve 7 and is rotatably mounted on a shaft 19 . The torque generated on the sleeve 7 is proportional to the pedal force and is used to drive the electric motor. Torque measurements can be made by strain gauges, angle encoders or other known direct and indirect methods.

[0026] An additional external spur gear toothing is also installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com