Production of a thin film reflector

A reflector and thin film technology, which is applied in the production field of thin film reflectors, can solve the problems of low reflectivity, limited useful temperature range of metal reflectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

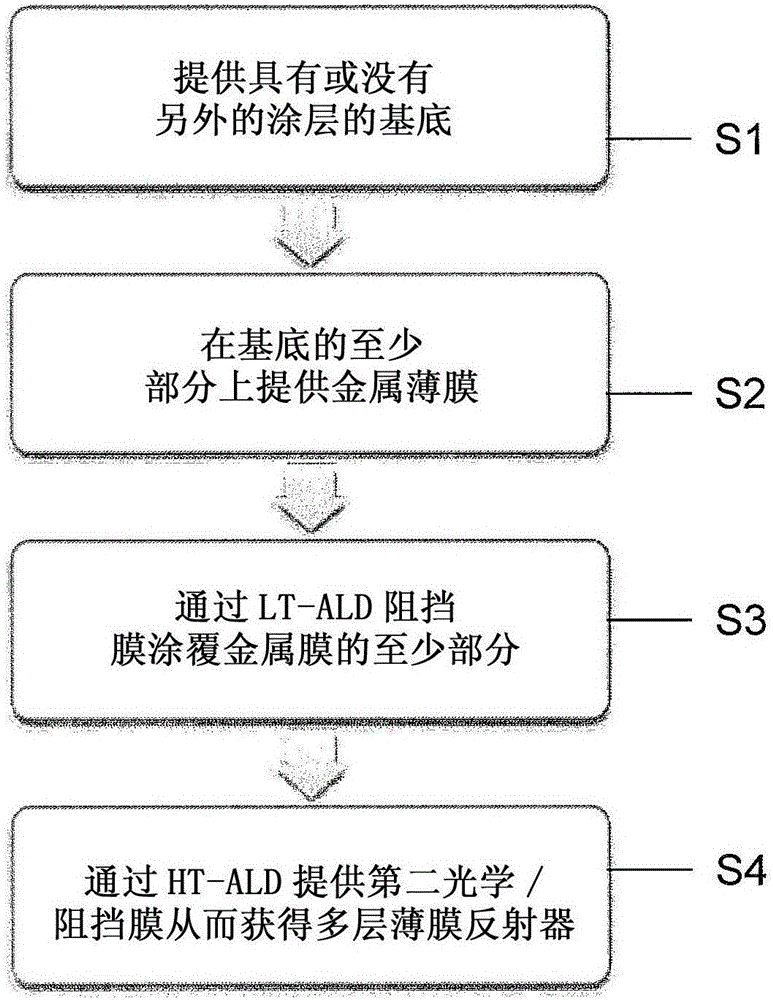

Method used

Image

Examples

Embodiment Construction

[0048] Throughout the drawings, the same reference numerals are used for similar or corresponding elements.

[0049] In order to better understand the proposed technique, it may be useful first to give a brief overview of the potential uses and applications of thin-film reflectors according to the proposed technique.

[0050] For example, a thin film reflector according to any of the disclosed embodiments can be used as a component of a high temperature lamp.

[0051] According to another example, a thin film reflector as described in any of the embodiments may be used as part of a scintillator for X-ray applications. In this application, the thin film reflector provides the reflective function for the secondary photons in the reflective scintillator. Due to the excellent heat resistance of the proposed thin-film reflector, it will be able to withstand thermal shocks due to excessive heat applied during the production phase of said scintillator and / or during use of the scinti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap