Excavation tool

A tool and drill bit technology, applied in the field of double-pipe excavation tools, can solve the problems of decreased drilling performance, enlarged diameter drill bit, large load, etc., and achieves the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

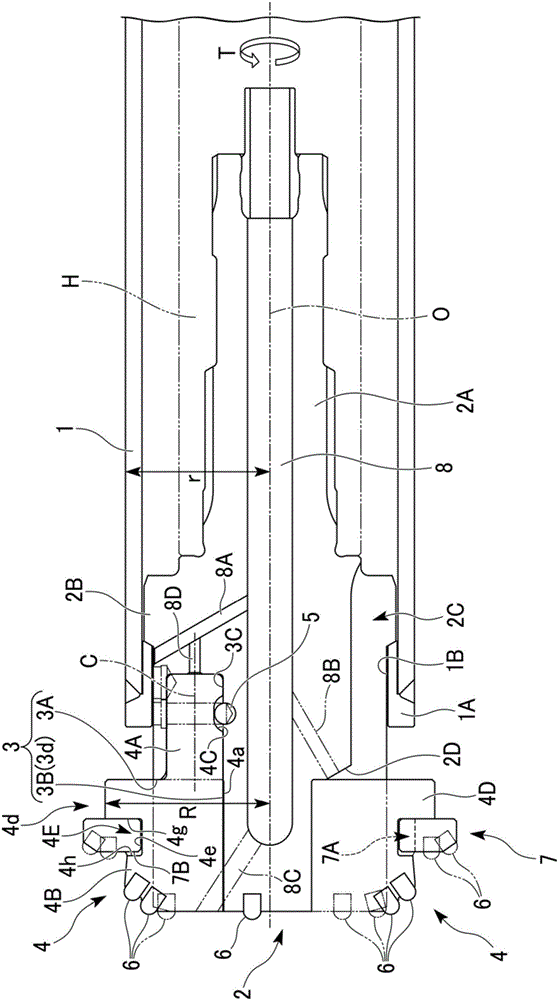

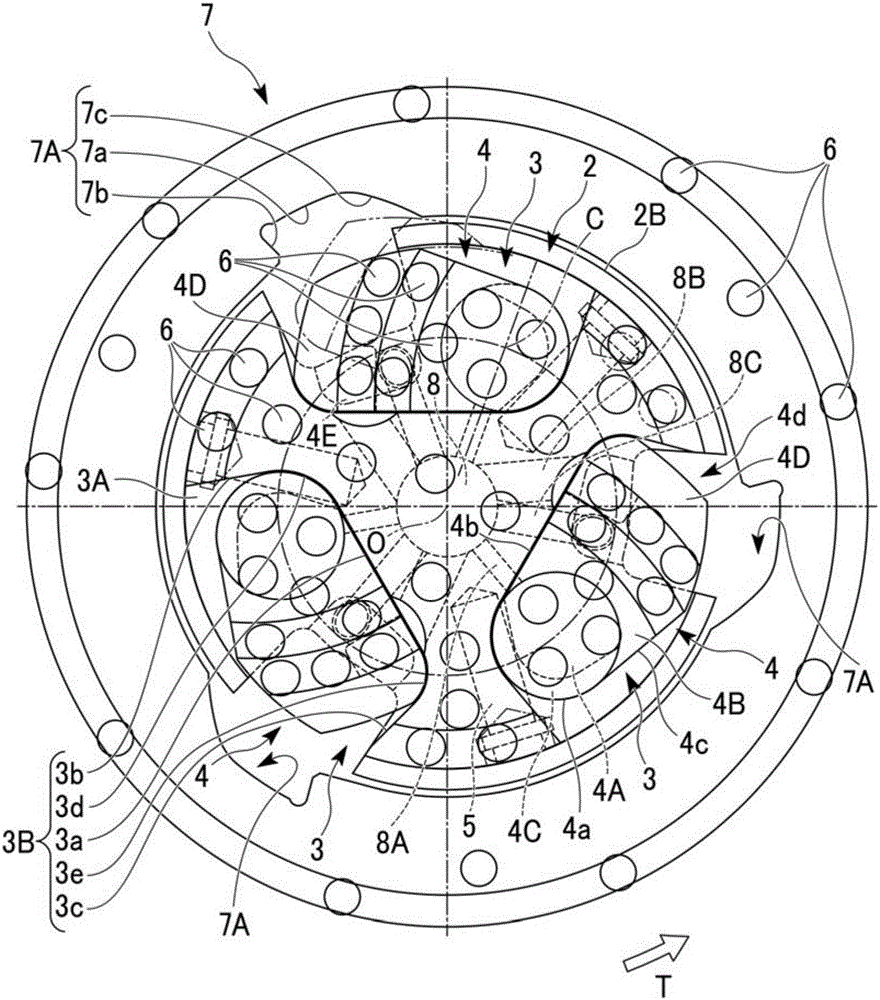

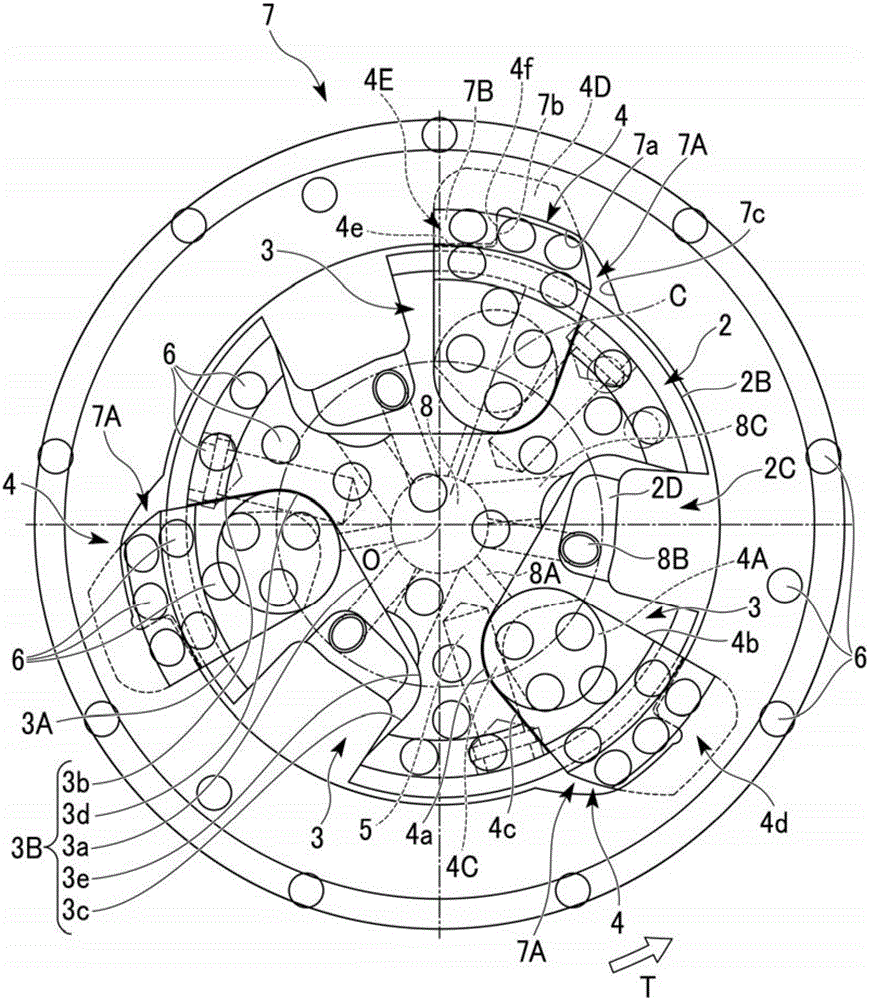

[0026] Figure 1 to Figure 5 It is a figure which shows one embodiment of the digging tool of this invention. In this embodiment, the bushing 1 is formed of a metal material such as steel into a cylindrical shape centered on the axis O, and at the front end of the bushing 1 ( figure 1 The left side part in ) is equipped with a sleeve top 1A which is also formed into a multi-stage cylindrical shape from a metal material such as steel.

[0027] The inner diameter of the sleeve top 1A is set to a constant inner diameter smaller than the inner diameter of the sleeve 1, and the outer diameter of the front end is set to be the same as the outer diameter of the sleeve 1, and the outer diameter of the rear end is set to be inserted into the The size of casing 1. The sleeve top 1A is integrated with the sleeve 1 so as to be coaxial with the sleeve 1 by fitting in the rear end portion of the sleeve top 1A from the front end side of the sleeve 1 and joining by welding or the like.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com