Cut product producing method and producing system

A production method and product technology, which is applied in the production of cutting products and the production system field, can solve problems such as lower yields and achieve the effect of increasing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

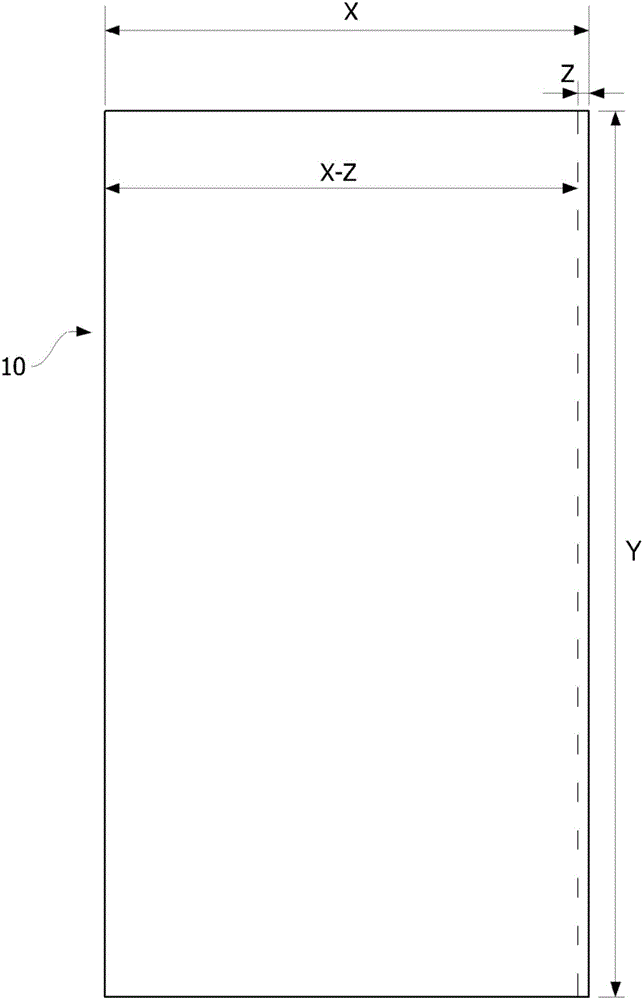

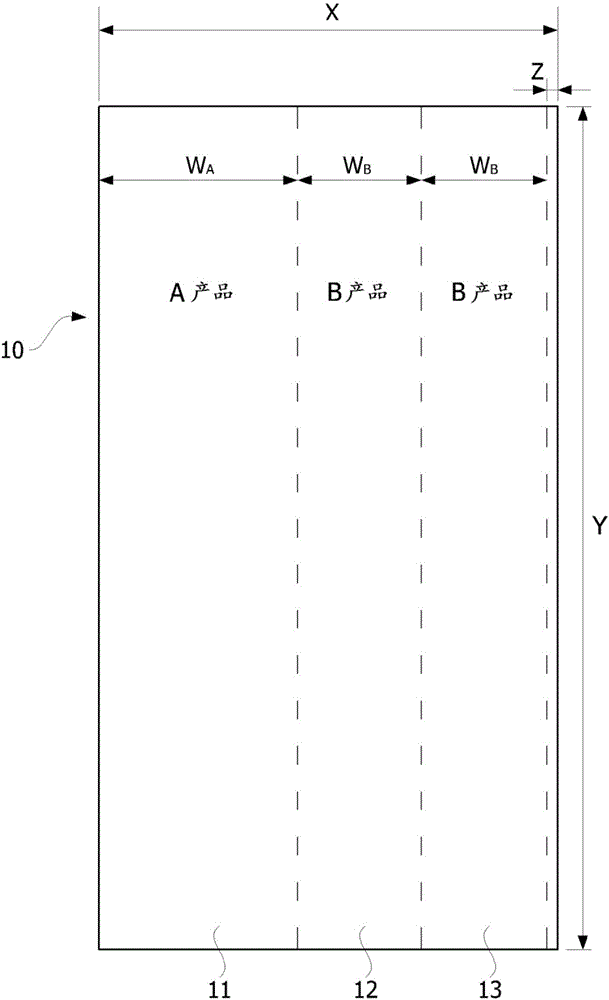

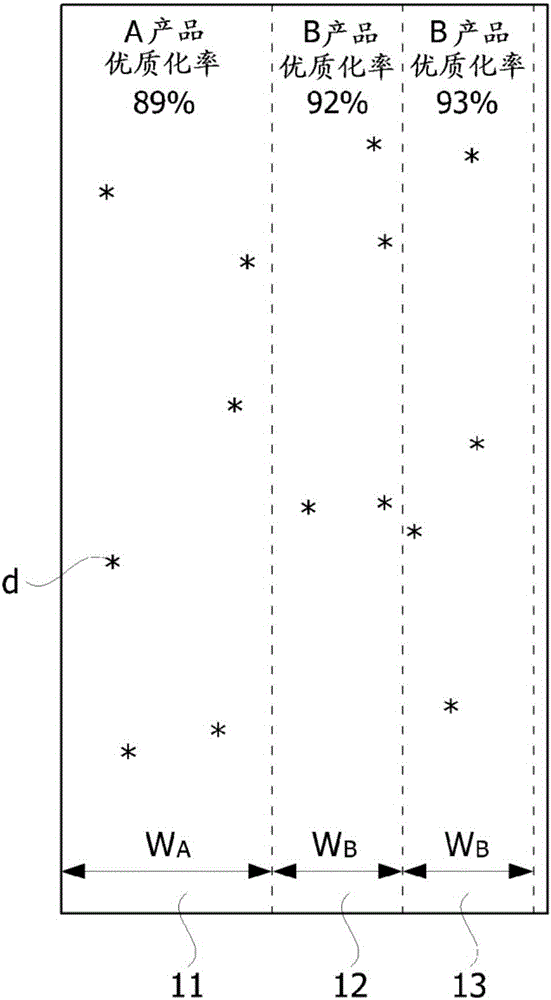

[0142] According to the second embodiment, it may include: a profit calculation step, selecting a cutting method in which the M value of the following general formula 3 presents the maximum value; a first cutting step, cutting and cutting the blank 10 along the length direction through the selected above-mentioned cutting method. obtaining a plurality of strips 11 , 12 , 13 ; and a second cutting step of cutting the obtained plurality of strips 11 , 12 , 13 along the width direction to obtain a single product 10 a.

[0143] [Formula 3]

[0144]

[0145] In the above general formula 3, n is the number of strips 11, 12, 13, T is the number of single products 10a produced from each strip, and P is the price of the single product 10a produced from each strip.

[0146] According to this embodiment, the cutting form with the highest yield can be realized by the above general formula 3. In order to explain this, the following content is illustrated.

[0147] Such as figure 2 a...

no. 3 approach

[0163] According to the third embodiment, the production method of the cut product of the present invention includes: a profit calculation step, selecting the cutting method that makes the R value of the following general formula 4 present the maximum value; a blank selection step, selecting from multiple Select the blank 10 from the blank 10; cut and cut the selected blank 10 along the length direction to obtain a plurality of strips 11, 12, 13; The step of cutting in the same direction to obtain the single product 10a.

[0164] [Formula 4]

[0165]

[0166] In the above general formula 4, m is the number of blanks 10 (m≥2), n is the number of strips 11, 12, 13 produced from each blank 10 (n≥2), and T is the 11 , 12 , and 13 produce the number of single items 10 a , and P is the price of each single item 10 a produced from each strip 11 , 12 , and 13 .

[0167] Specifically, first, a clipping method that maximizes the R value of the above general formula 4 is selected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com