Molecular gradient forward and reverse ultrafiltration separation and purification device and ultrafiltration method thereof

An ultrafiltration separation and purification method technology, applied in the field of biological and molecular ultrafiltration separation and purification, can solve the problems of waste of experiments, complicated operation, termination time, etc., and achieve the effect of small hazard risk and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

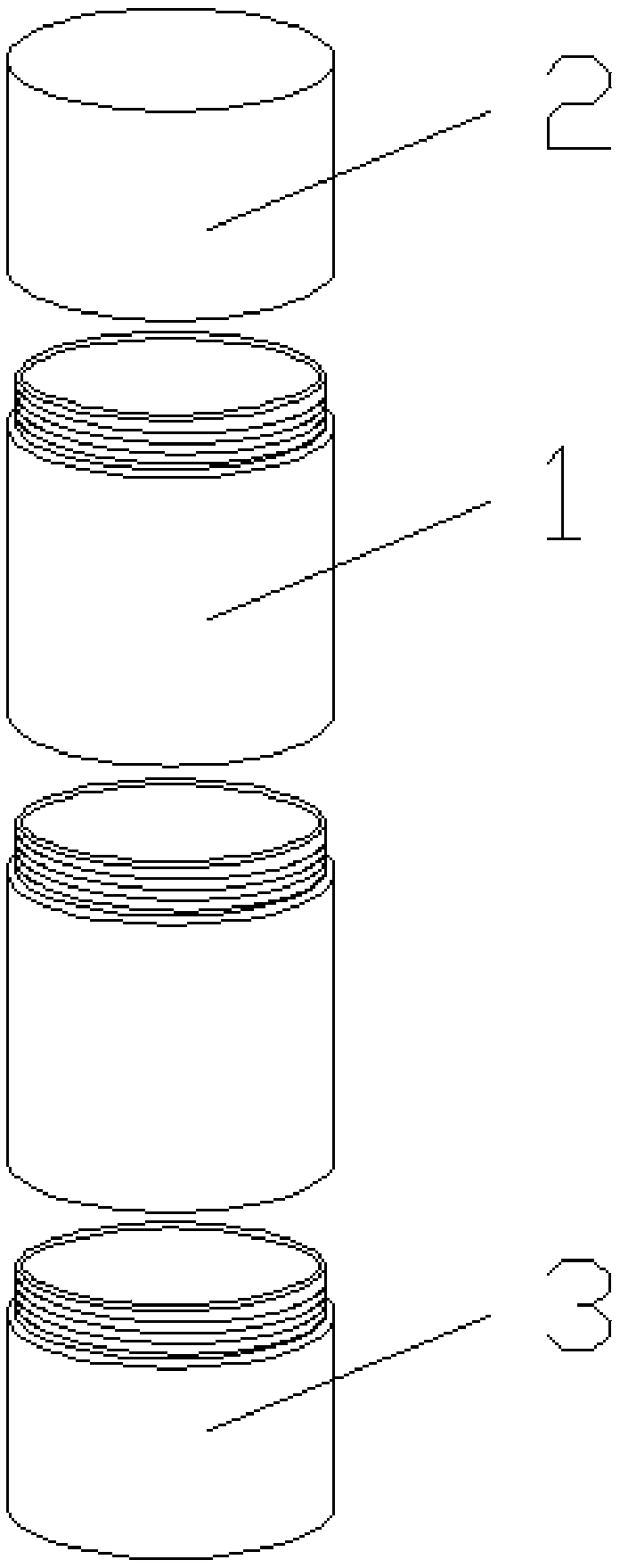

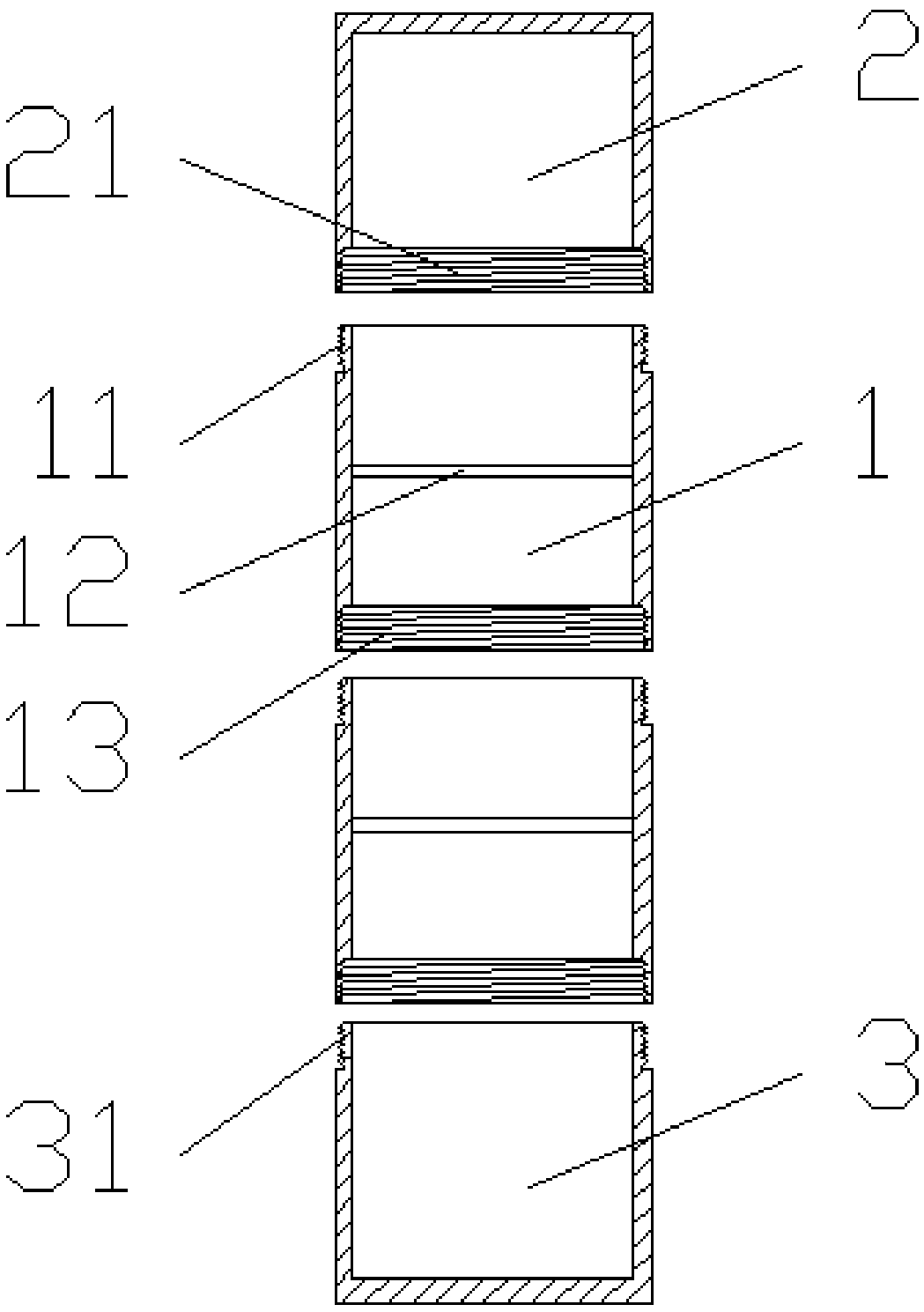

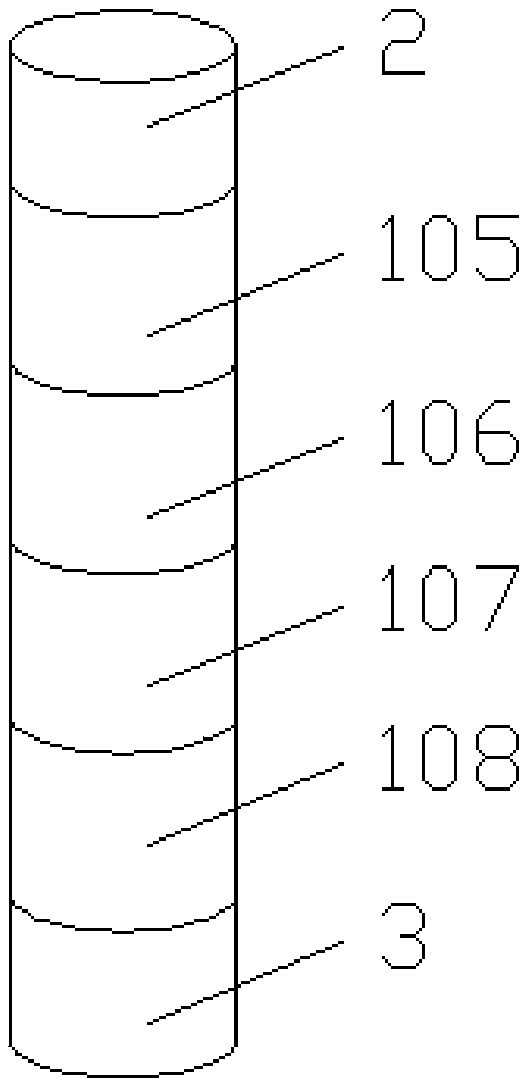

[0033] Such as Figure 1-2 As shown, the molecular gradient forward and reverse ultrafiltration separation and purification device disclosed in the present invention includes an end capper and at least two ultrafiltration units 1. The ultrafiltration unit 1 includes a tube body and an ultrafiltration membrane 12, and the tube body is arranged radially The ultrafiltration membrane 12 is detachably connected in the axial direction between adjacent ultrafiltration units 1. The apertures (maximum passable molecular weight) of the ultrafiltration membranes 12 of adjacent ultrafiltration units 1 are different. The ultrafiltration units 1 at both ends are respectively connected to the sealing One end of the pipe body is provided with an internal thread a11, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com