a leaf blower

A leaf blower and machine body technology, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of complex structure of the air volume adjustment device, affecting the effect of blowing leaves, inconvenient use or maintenance, etc., to improve grip comfort, structure Simple, easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

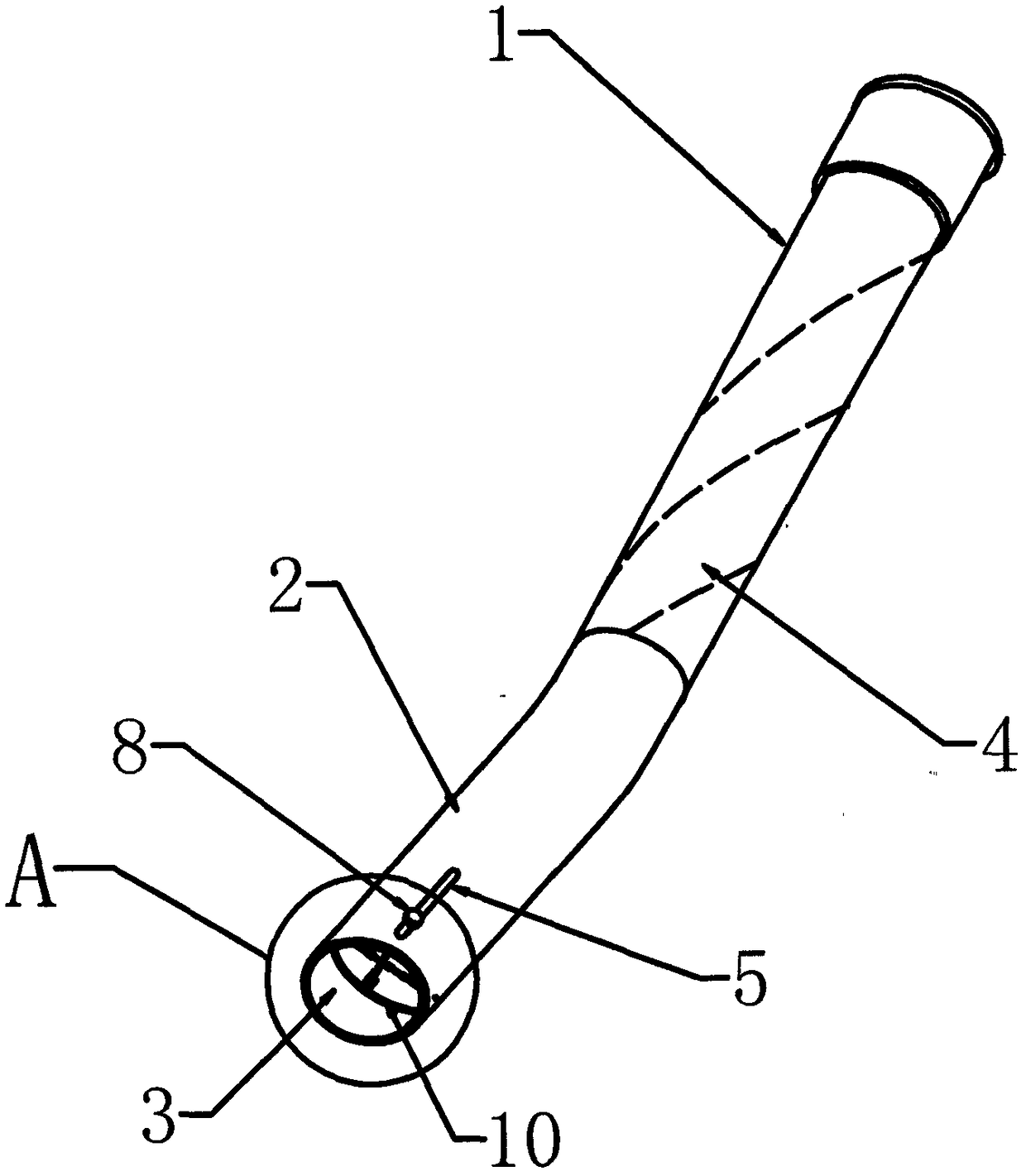

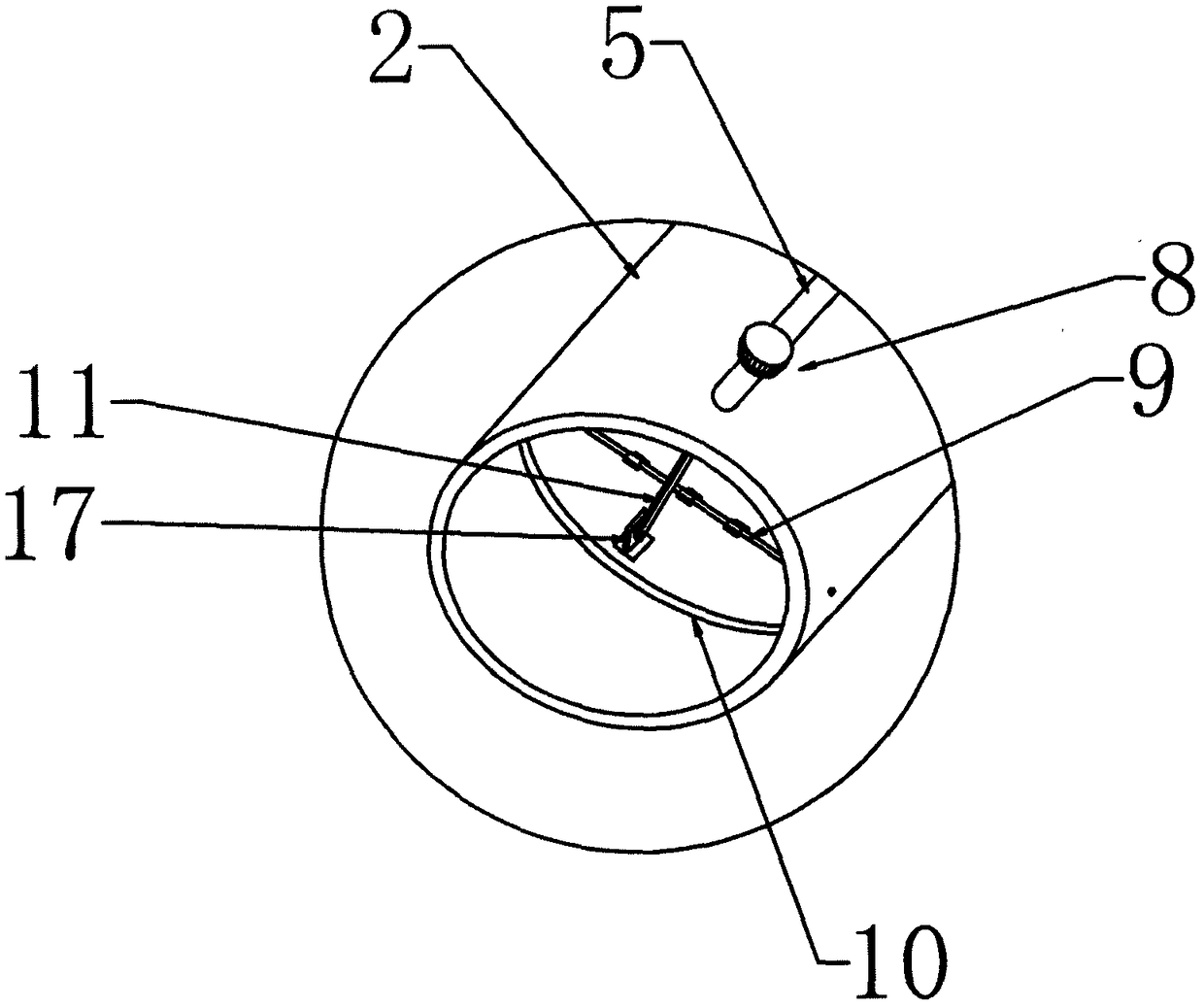

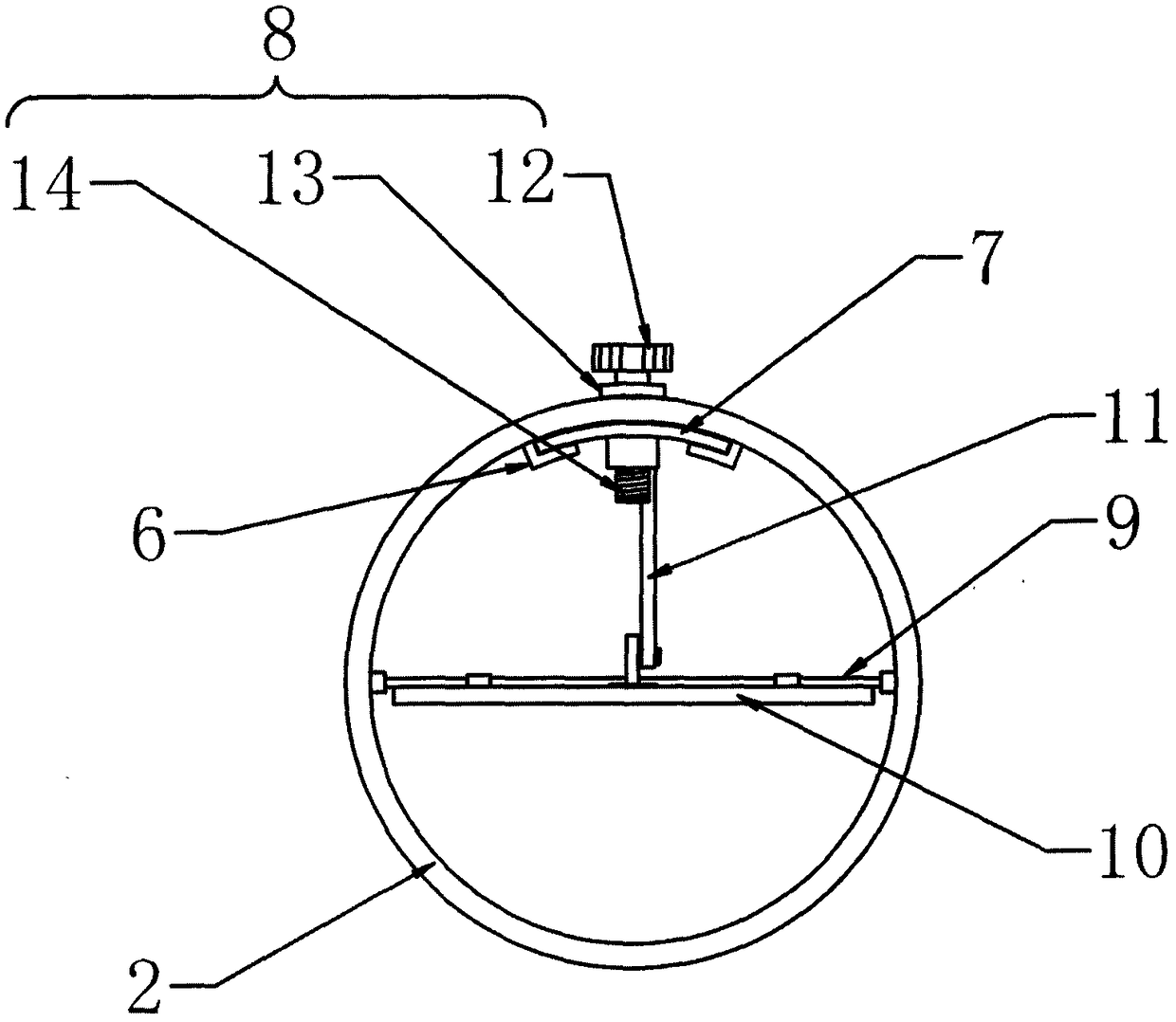

[0028] Such as Figure 1 to Figure 2 Shown, a kind of leaf blower comprises a body (not shown in the figure) with blowing function, a hollow blowpipe 1 connected to the body at one end, the wind blown out of the body passes through the blowpipe 1, as an improvement of the present invention, the blowpipe The air outlet end of 1 is provided with a blowing nozzle 2, and the blowing nozzle 2 is provided with an adjusting device 3 for adjusting the air volume. When using the leaf blower, the area and shape of the air outlet end of the blowing nozzle 2 can be easily adjusted to change the blowing speed. Easy to use; at least two helical curved surfaces 4 extending from the air inlet end to the air outlet end and intertwined are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com