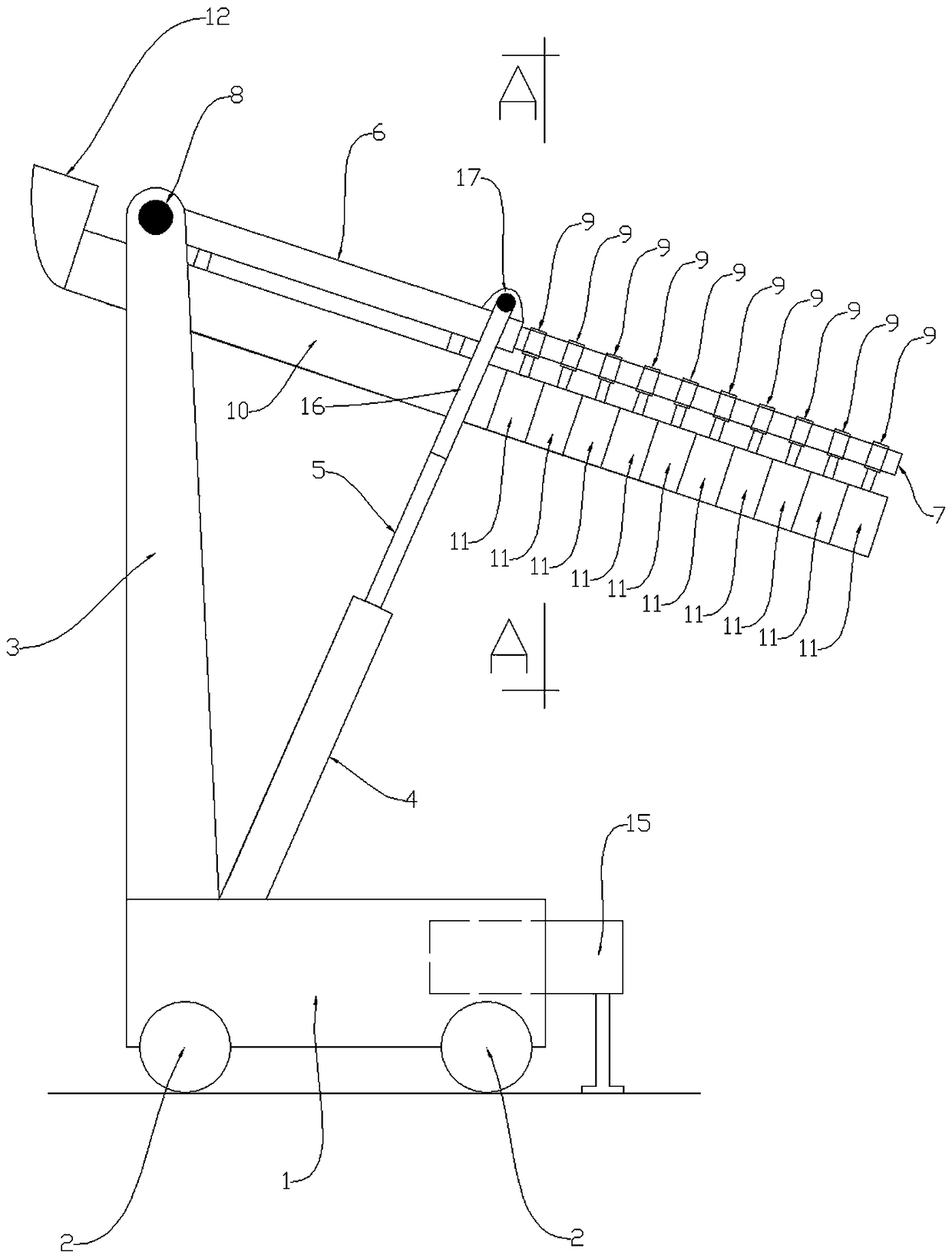

An improved telescopic movable chute

A mobile and improved technology, applied in the field of pouring concrete, can solve the problems of low pouring efficiency, waste of concrete, high labor intensity of workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

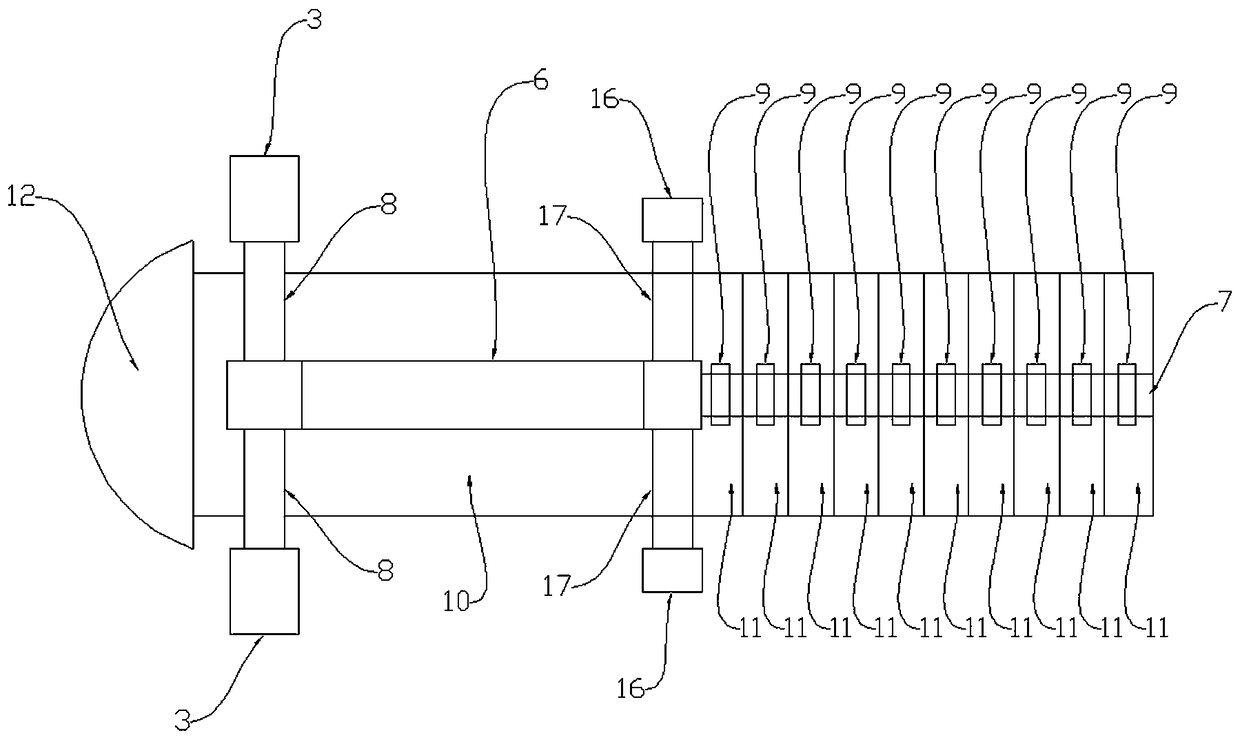

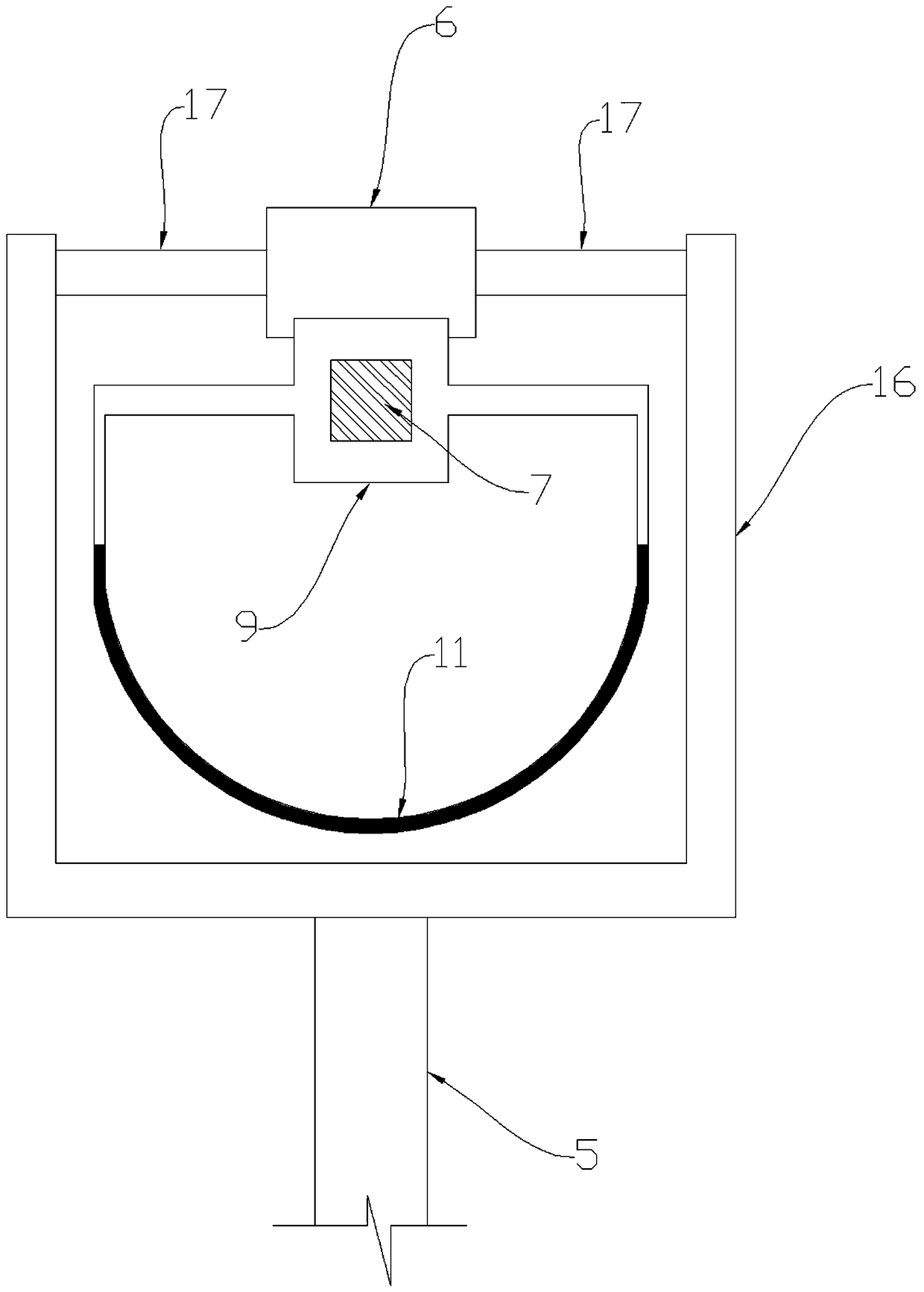

[0011] The content of the invention has described the specific implementation of the present invention in detail, and will not repeat it here; it needs to be explained: 1. The shaft section of the telescopic rod 7 matches the hole 13, and the shaft section of the telescopic rod 7 is either square or elliptical shape, or any shape other than a circle, because if the shaft section of the telescopic rod 7 is circular, the hole 13 of the movable frame 9 can rotate around the telescopic rod 7; two, the present invention is an applied for patent " A telescopic mobile chute”, application number: 2017100821172 improved version, it designs the arm (6) and the telescopic rod (7) above the chute, avoiding the influence of the concrete dripping in the movable chute 11 on the telescopic rod 7 Defects in normal operation, at the same time, the hydraulic cylinder 4 is arranged at the left end of the vehicle frame 1, which increases the anti-overturning moment of the vehicle body. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com