Novel device for repairing inner wall of special kiln

A new type of detection device technology, applied in lining repair and other directions, can solve the problems of high cost, long downtime, complicated operation, etc., and achieve the effects of convenient operation, reduced production cost and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

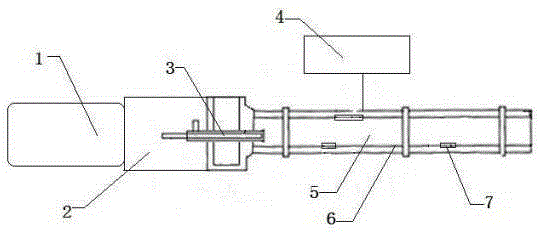

[0012] This embodiment provides a new type of special kiln inner wall repairing device, which is characterized in that: the new type of special kiln inner wall repairing device includes furnace repair material equipment (1), fuel system (2), burner (3), infrared detection device ( 4) Kiln chamber (5), inner wall of kiln (6), damaged parts of inner wall (7);

[0013] Among them: the device is mainly composed of infrared detection device (4), furnace repair material equipment (1), combustion system (2) and kiln body. The kiln body is composed of kiln (5), kiln wall and kiln inner wall (6). The center of the inner wall (6) is the kiln (5), the furnace repair material equipment (1) is connected with the fuel system (2), the fuel system (2) is connected with the burner (3), and the burner (3) extends into the kiln Inside the chamber (5).

[0014] The kiln body is externally connected with an infrared detection device (4) to detect the position of the damaged part (7) on the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com