Thrust plain bearings

A thrust sliding bearing, sliding bearing technology, applied in sliding contact bearings, bearings, bearings in rotating motion, etc., can solve problems such as consumption and heavy workload, and achieve the effect of inhibiting sliding and smooth relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

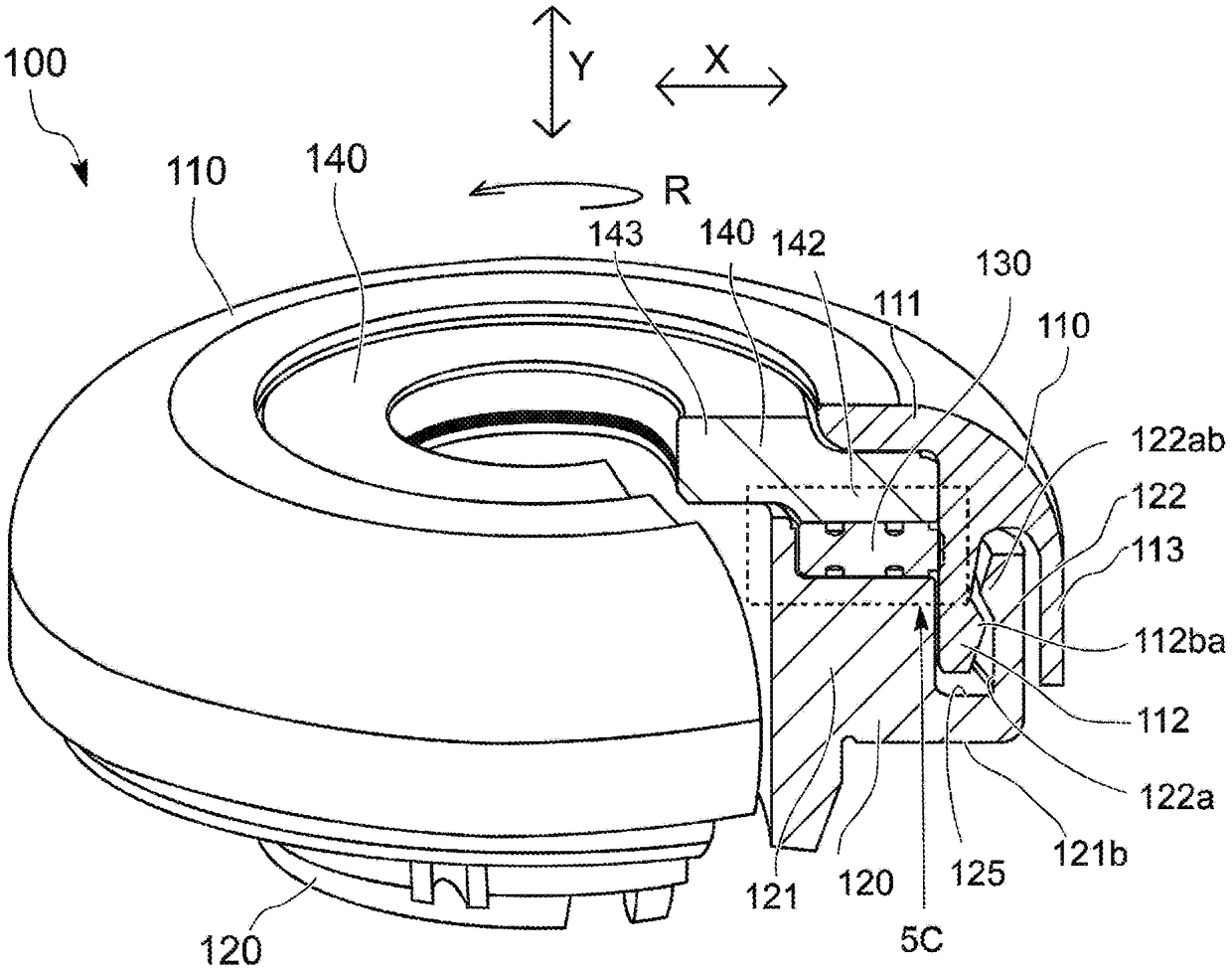

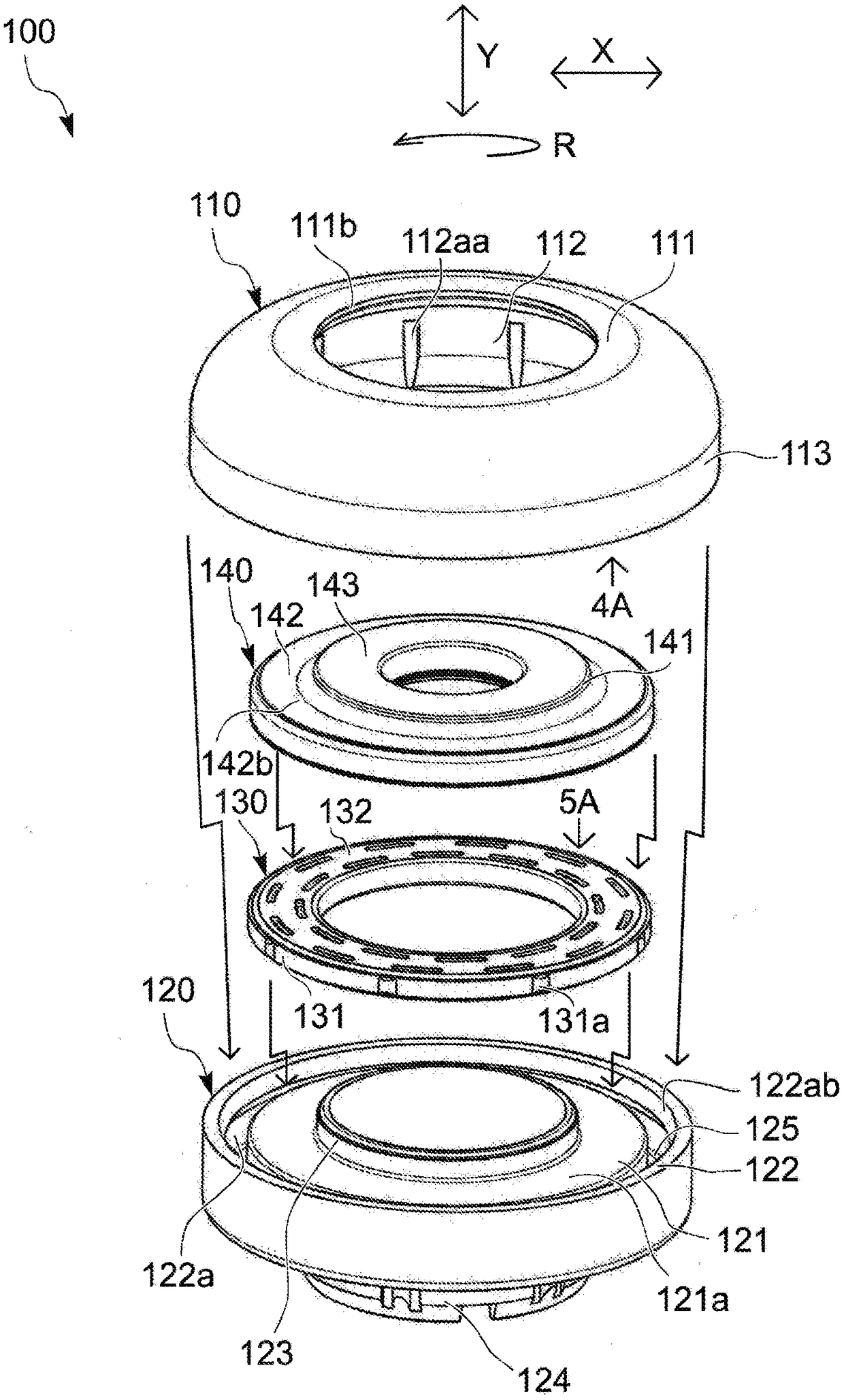

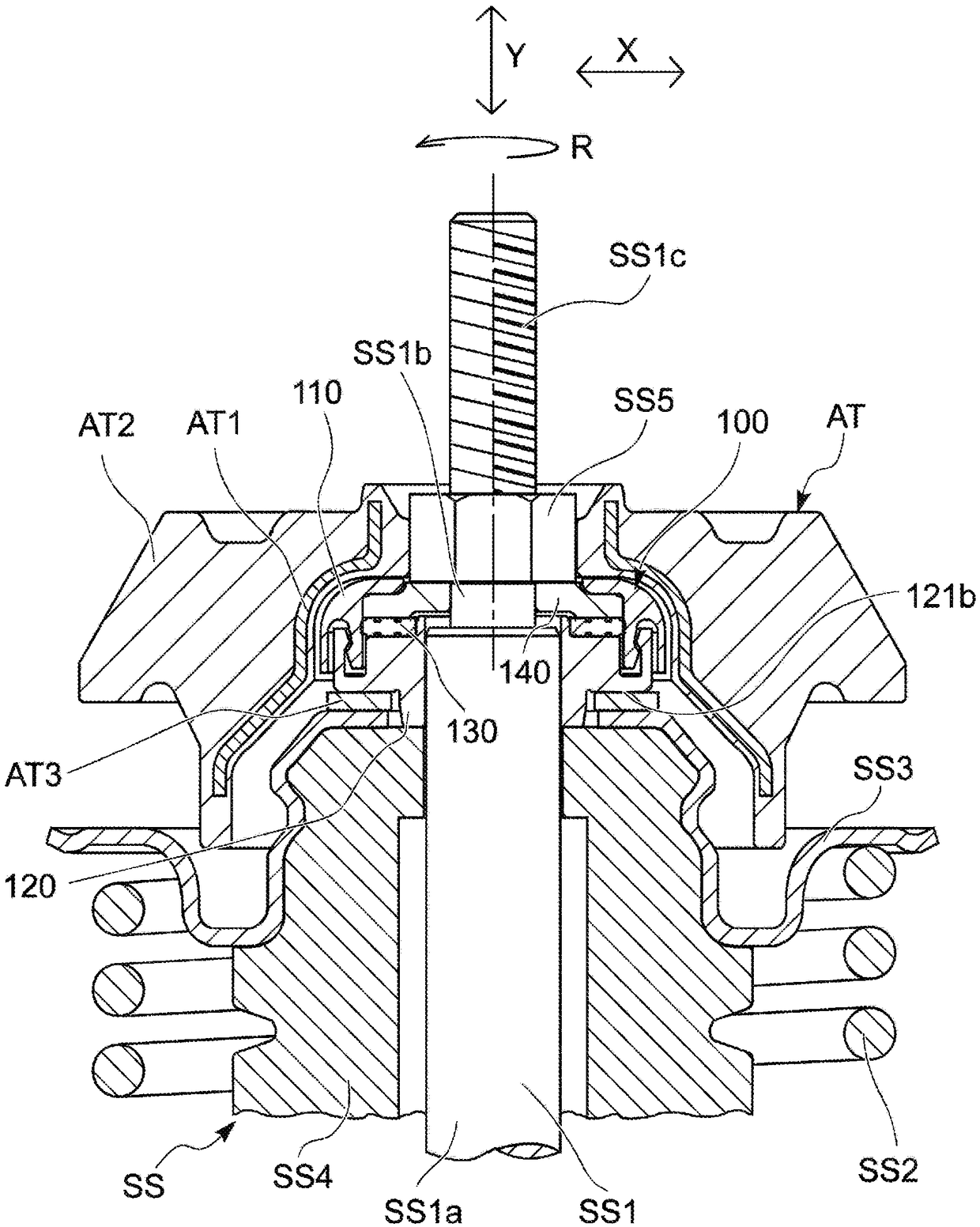

[0047] The thrust sliding bearing of the present invention comprises: an annular upper shell, which is inserted into the upper front end of the piston rod used in the shock absorber of the strut type suspension; an annular lower shell, which surrounds the axis of the piston rod, Rotatably overlapped with respect to the upper case; a ring-shaped synthetic resin sliding bearing piece is sandwiched in the annular space formed between the upper case and the lower case and receives the thrust load of the piston rod; and a ring-shaped metal plate , fixed to the piston rod, sandwiched between the upper shell and the synthetic resin sliding bearing piece, wherein the upper shell is integrally composed of an annular upper shell base and an upper shell cylindrical portion, and the annular upper shell The base portion forms an annular lower surface, the upper shell cylindrical portion hangs from the annular lower surface of the upper shell base and fits into the lower shell, and a synthet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com