Stator enabling good shim bearing capacity while optimising the magnetic circuit, and method for electrical insulation of said stator

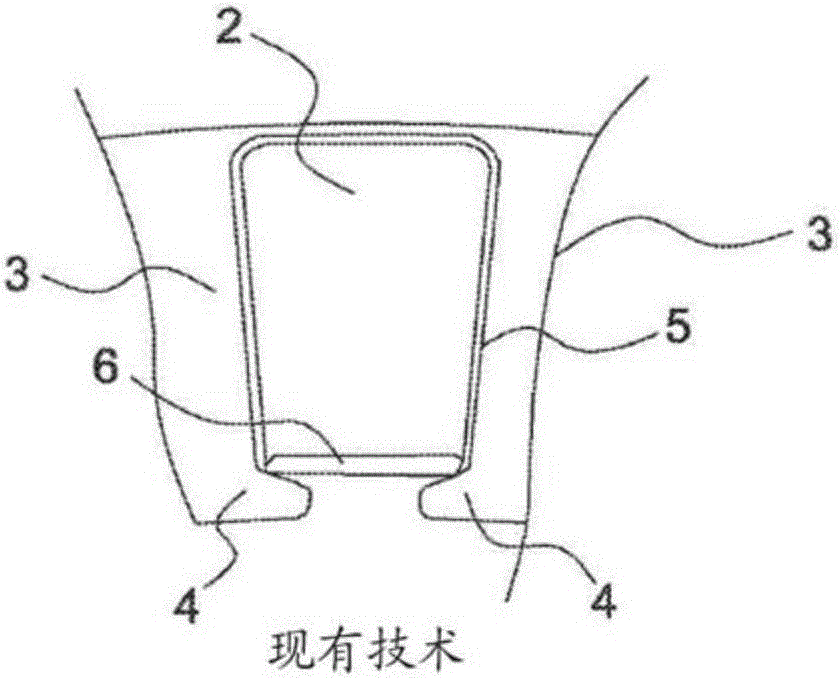

A technology for stators and insulators, applied in the shape/style/structure of winding insulation, laying solid insulation, starting motors for engines, etc. It can solve the problem that the slot entrance opening cannot be made smaller than the width of the conductive wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

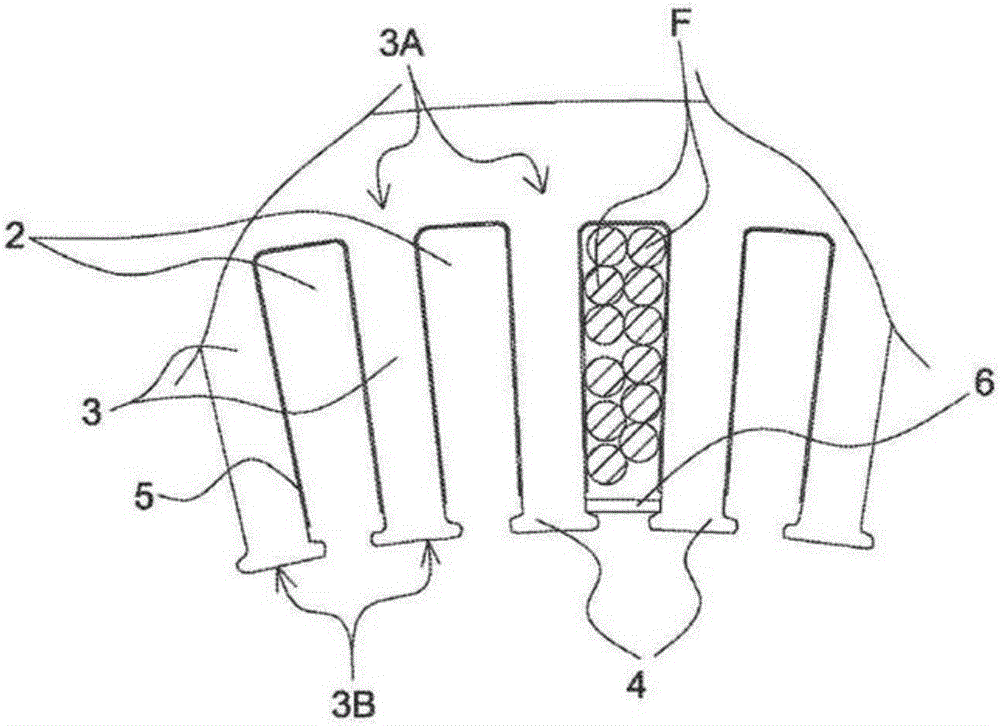

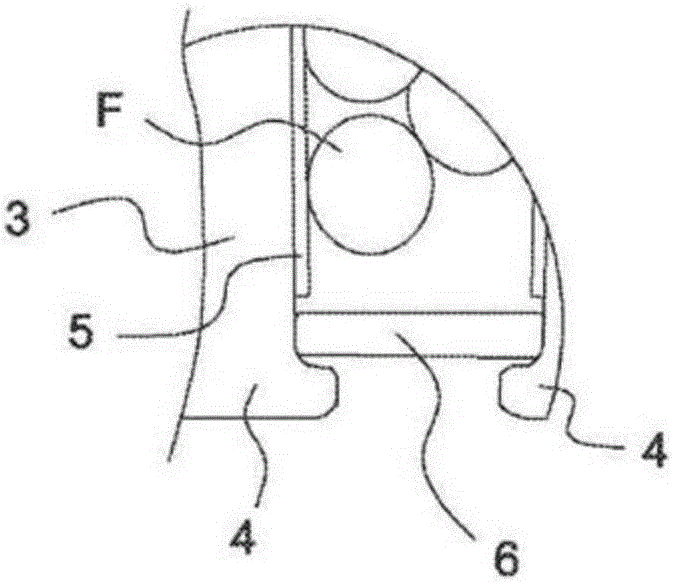

[0039] Reference is made to said figures in order to describe advantageous embodiments, but in a non-limiting way, for the method for manufacturing a stator and for depositing an insulating coating according to the invention.

[0040]In this description and in the claims, the terms "near" and "upper" refer to elements closer to the outer periphery of the stator, i.e. closer to the housing, according to a direction radial to the axis of rotation X of the rotating electrical machine, Whereas the terms "distal" and "lower" refer to elements close to the inner periphery of the stator, ie close to the rotor.

[0041] The stator 21 according to the invention is constituted by a plurality of plates 1a, 1b, 1c,..., 1n forming a set of plates 1 having a generally cylindrical form, the stator having a plurality of radial slots 2, each slot The mouth is delimited by two adjacent teeth 3 that extend radially and are connected to each other by their proximal end 3A and whose distal end 3B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com