A water sealing device for tail gas purification in chemical storage tanks

A technology of exhaust gas purification and water sealing device, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of hindering the suction of storage tanks, negative pressure of storage tanks, low safety, etc., and avoid sludge Blocking and ensuring unobstructed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

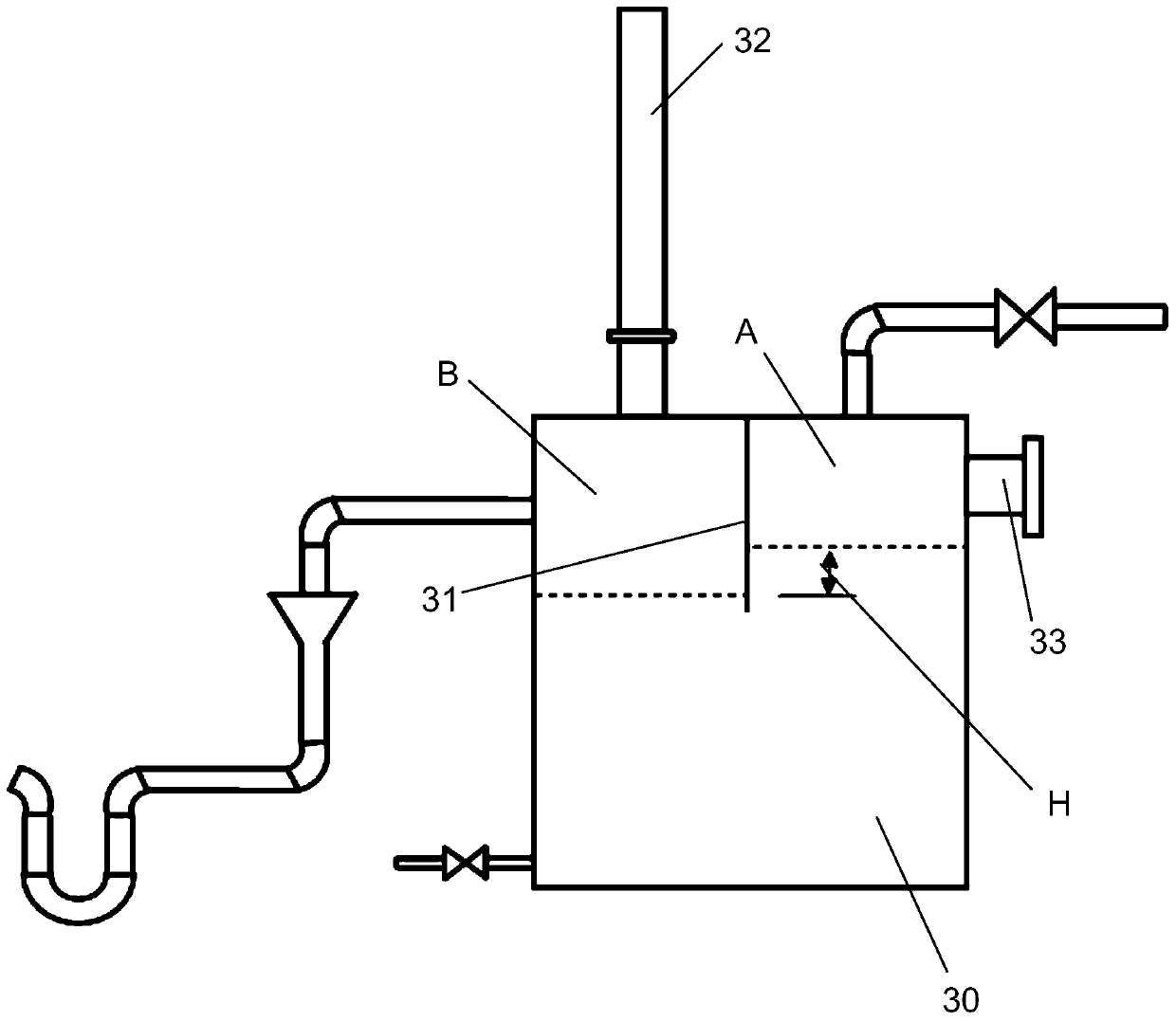

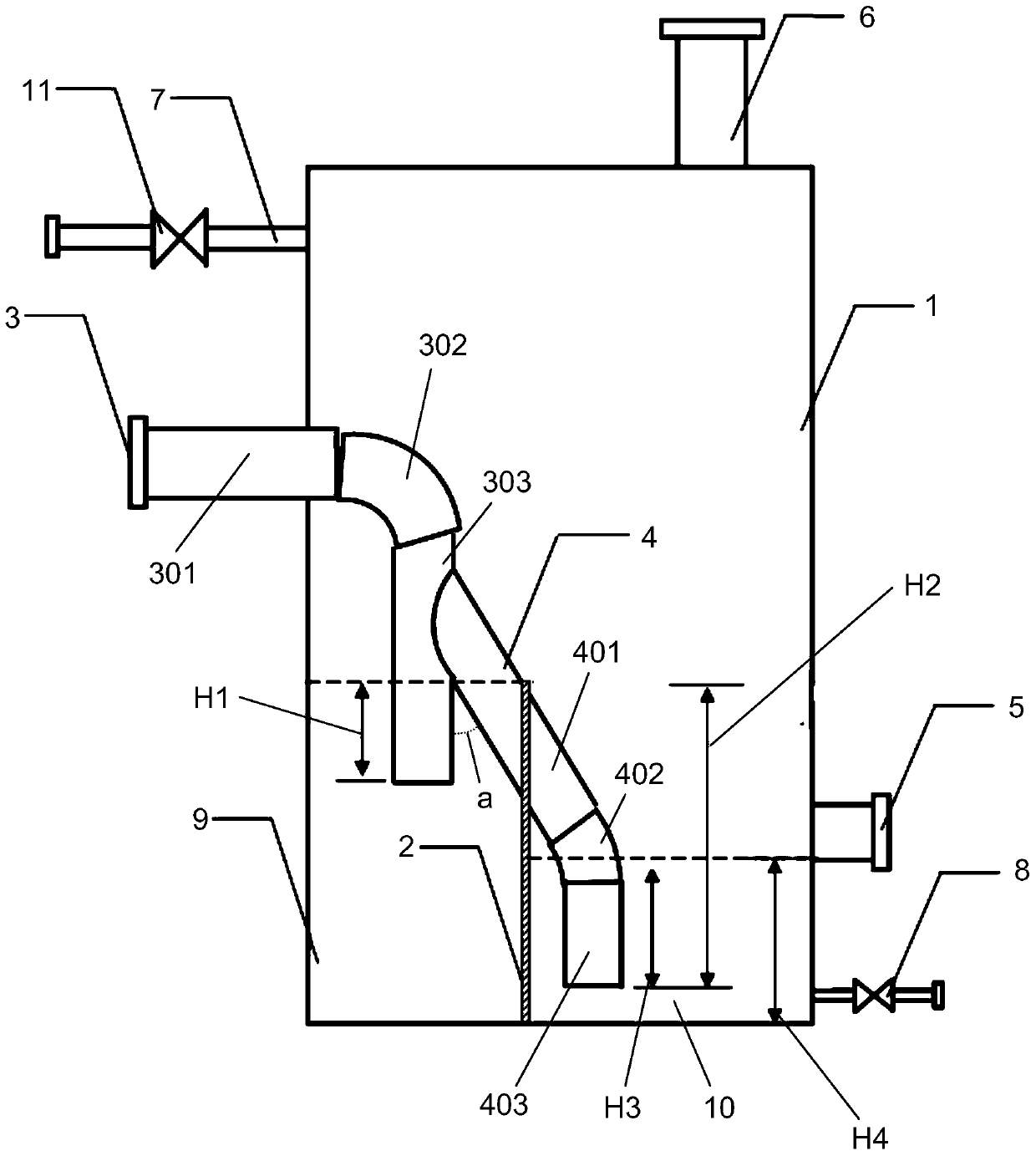

[0025] Please combine figure 2 As shown, a kind of water sealing device used for purification of tail gas in chemical storage tanks of the present invention is the same as the prior art in that it also includes a water tank 1 and an exhaust pipe 6 connected to the top of the water tank, which will not be repeated here. Different from the prior art, it also includes a baffle 2, an intake pipe 3, a water storage pipe 4, a water supply pipe 7, an overflow pipe 5 and a sewage pipe 8, and the baffle 2 is erected at the inner bottom of the water tank 1 to The interior of the water tank is divided into a water purification chamber 9 and a sewage chamber 10. The air intake pipe 3 includes an air intake horizontal pipe 301, an air intake elbow 302 and an air intake vertical pipe 303. One end of the air intake horizontal pipe 301 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com