Gasoline hydrogenation catalyst and preparation method thereof

A gasoline hydrogenation and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low hydrodesulfurization activity, improve catalytic activity, reduce Interaction, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

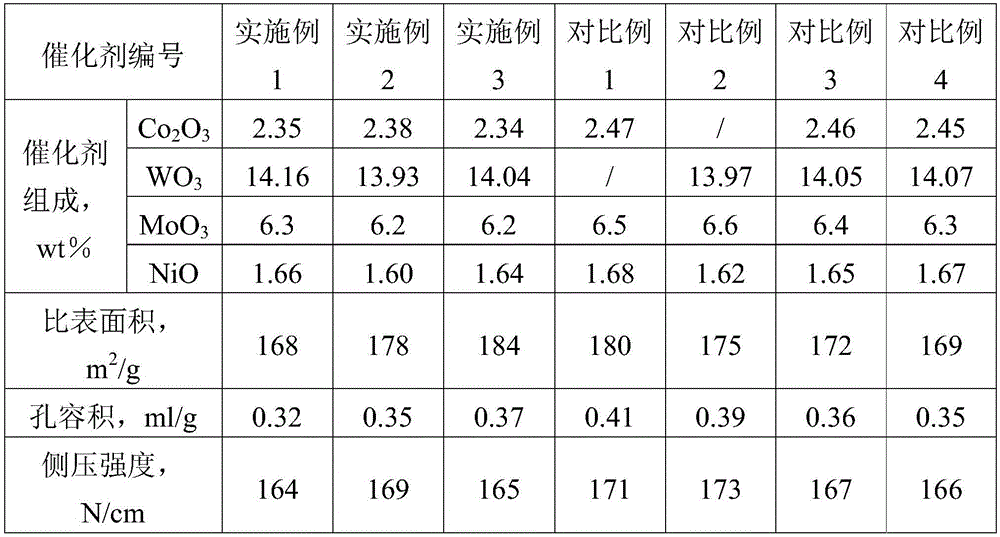

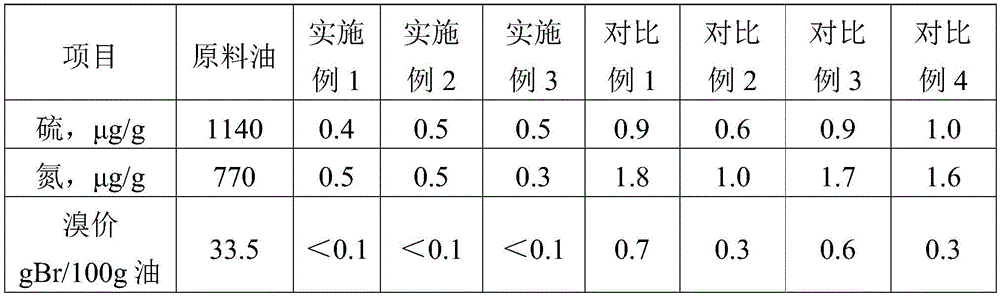

Examples

Embodiment 1

[0045] (1) γ-Al 2 o 3 Vector preparation

[0046] Take by weighing 500g of silicon-free pseudo-boehmite powder, 30g of turmeric powder, 30g of citric acid, 300ml of 3-5% dilute nitric acid and mix evenly, extrude with extruder, dry at 120°C for 4 hours, and roast at 550°C for 5 After hours, get γ-Al 2 o 3 carrier.

[0047] (2) Get the γ-Al that 150g step (1) obtains 2 o 3 , with 150g mesoporous Al 2 o 3 Mix well (mesoporous Al 2 o 3 Specific surface area 250~350m 2 / g, pore volume 0.2~0.3m 3 / g, pore size 3~5nm), the mixture of the two is used as a composite carrier, denoted as F1.

[0048] (3) Preparation of Co / F1

[0049] Prepare 500ml impregnation solution: weigh 60g of tartaric acid and add it to 400ml of deionized water, stir and heat to 50°C, weigh 23.1g of cobalt nitrate (industrial grade) and 16.3g of ammonium dihydrogen phosphate (industrial grade) into the solution , boil for 0.5 hours. After cooling to room temperature, the solution was transferred to...

Embodiment 2

[0058] (1) γ-Al with TS molecular sieve 2 o 3 Preparation of vector

[0059] Weigh 450g of silicon-free pseudo-boehmite powder, 50g of TS molecular sieve, 30g of turnip powder, 30g of citric acid, 300ml of 3-5% dilute nitric acid and mix evenly, extrude with extruder, dry and roast to obtain γ-Al with TS molecular sieve 2 o 3 Carrier, abbreviated as TSA.

[0060] (2) Get the TSA that 200g step (1) obtains, and 100g mesoporous Al 2 o 3 Mix evenly (specific surface area 250~350m 2 / g, pore volume 0.2~0.3m 3 / g, pore size 3~5nm), the mixture of the two is used as a composite carrier, denoted as F2.

[0061] (3) Preparation of Co / F2

[0062] The preparation of the dipping solution is the same as step (3) of Example 1.

[0063] Weigh 300g of the TSA carrier prepared in step (1), measure 230ml of the cobalt-containing impregnation solution prepared above, impregnate with equal volume for 1h, dry and roast to obtain a semi-finished catalyst.

[0064] (4) Preparation of Co-...

Embodiment 3

[0071] (1) γ-Al 2 o 3 Preparation of vector

[0072] Weigh 300g of silicon-containing pseudo-boehmite, 40g of fenugreek powder, 23g of oxalic acid, and 200ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry and roast them to obtain γ-Al 2 o 3 carrier.

[0073] (2) Get the γ-Al that 250g step (1) obtains 2 o 3 , with 50g mesoporous Al 2 o 3 Mix evenly (specific surface area 250~350m 2 / g, pore volume 0.2~0.3m 3 / g, pore size 3~5nm), the mixture of the two is used as a composite carrier, denoted as F3.

[0074] (3) Preparation of Co / F3

[0075]Prepare 500ml impregnation solution: weigh 80.0g oxalic acid and add it to 400ml water, stir and heat to 60°C, weigh 30g basic cobalt carbonate (industrial grade) and 21g phosphoric acid (industrial grade) into the solution, boil for 0.5 hours , cooled to room temperature, the solution was transferred to a volumetric flask, and water was added to make up to 500ml to obtain a cobalt-containing impre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap