A kind of catalyst for the semihydrogenation of acetylenic alcohol to enol and its preparation method

A catalyst and semi-hydrogenation technology, applied in the direction of hydrogenation preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unsuitable for industrialization and adverse environmental effects, and achieve high product selectivity and yield, The effect of long service life and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

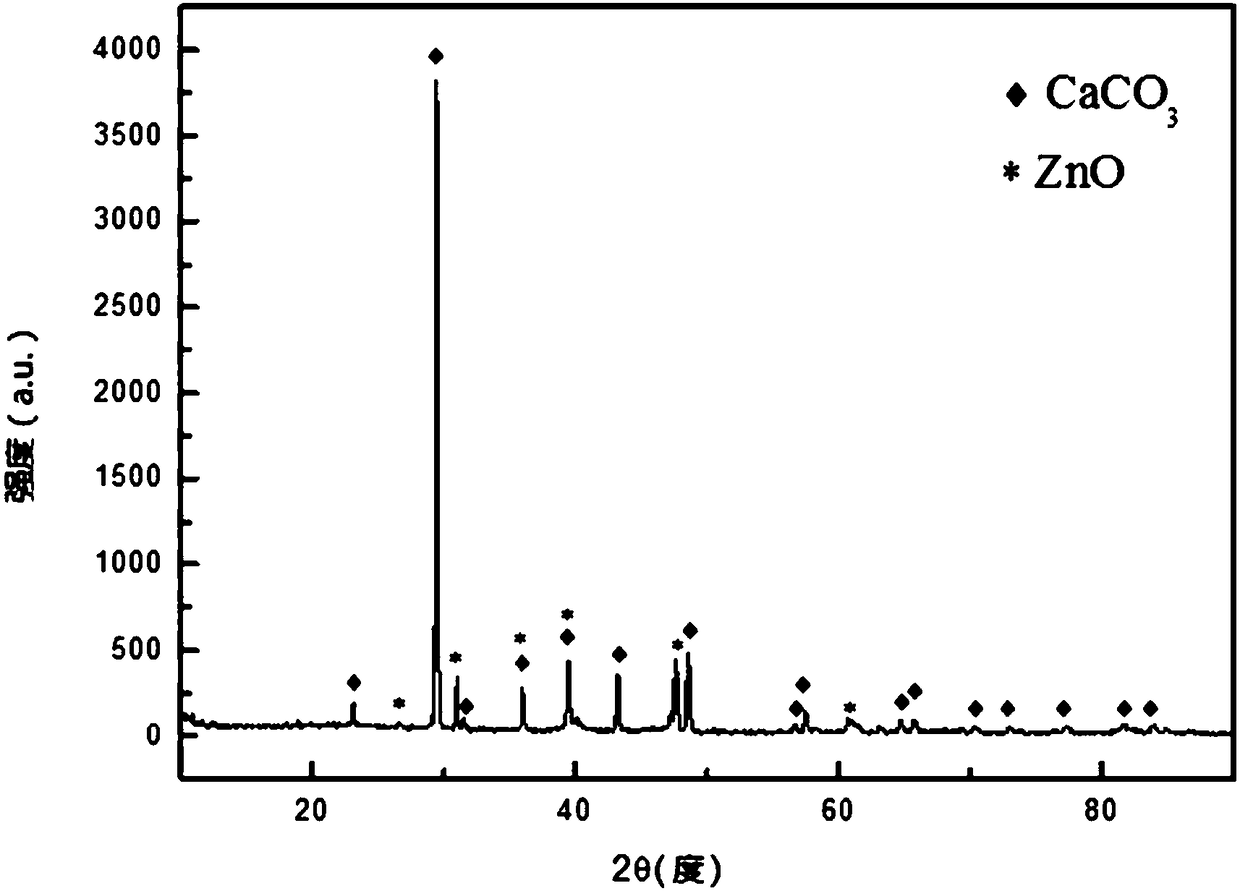

Image

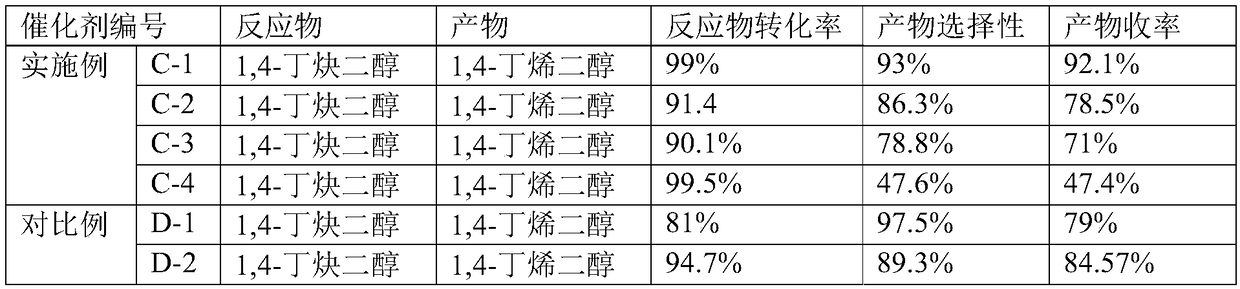

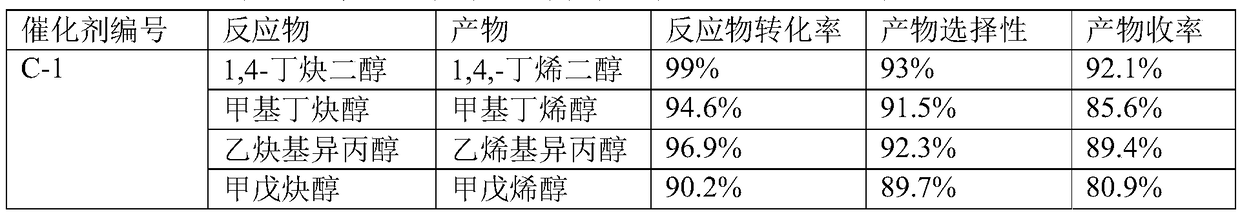

Examples

Embodiment 1

[0054] Add 400mL of concentrated hydrochloric acid with a concentration of 37% to 0.45kg of palladium chloride powder and heat to 60°C to dissolve to form solution A; add 10L of deionized water to 5kg of calcium carbonate with a particle size of 200 mesh and stir for 30min to form a milky white milky cloud Solution B; Dissolve 375g of anhydrous sodium carbonate with 7.5L of deionized water at room temperature and slowly add 305mL of formic acid dropwise until no gas is released (at this time the temperature is about 60°C) to form solution C; then add solution A to In emulsion B, after stirring for 5 minutes, heat up to 80°C and keep warm for 10 minutes to obtain brownish-yellow emulsion AB; then quickly add solution C with a temperature of about 60°C to emulsion AB at one time, and heat up to 85°C , then keep warm and stir for 30min until no gas is released, filter while hot, and wash the filter cake 3 times with deionized water until there is no Cl - , dried and weighed to ob...

Embodiment 2

[0056] Add 400mL of concentrated hydrochloric acid with a concentration of 37% to 0.45kg of palladium chloride powder and heat to 60°C to dissolve to form solution A; add 10L of deionized water to 5kg of calcium carbonate with a particle size of 200 mesh and stir for 30min to form a milky white milky cloud Solution B; Dissolve 375g of anhydrous sodium carbonate with 7.5L of deionized water at room temperature and slowly add 305mL of formic acid dropwise until no gas is released (at this time the temperature is about 60°C) to form solution C; then add solution A to In emulsion B, after stirring for 5 minutes, heat up to 80°C and keep warm for 10 minutes to obtain brownish-yellow emulsion AB; then quickly add solution C with a temperature of about 60°C to emulsion AB at one time, and heat up to 85°C , then keep warm and stir for 30min until no gas is released, filter while hot, and wash the filter cake 3 times with deionized water until there is no Cl - , dried and weighed to ob...

Embodiment 3

[0058] Add 400mL of concentrated hydrochloric acid with a concentration of 37% to 0.45kg of palladium chloride powder and heat to 60°C to dissolve to form solution A; add 10L of deionized water to 5kg of calcium carbonate with a particle size of 200 mesh and stir for 30min to form a milky white milky cloud Solution B; Dissolve 375g of anhydrous sodium carbonate with 7.5L of deionized water at room temperature and slowly add 305mL of formic acid dropwise until no gas is released (at this time the temperature is about 60°C) to form solution C; then add solution A to In emulsion B, after stirring for 5 minutes, heat up to 80°C and keep warm for 10 minutes to obtain brownish-yellow emulsion AB; then quickly add solution C with a temperature of about 60°C to emulsion AB at one time, and heat up to 85°C , then keep warm and stir for 30min until no gas is released, filter while hot, and wash the filter cake 3 times with deionized water until there is no Cl - , dried and weighed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com