High-rigidity frame bed body for aluminum piston blank casting machine

A technology of frame bed and casting machine, which is applied in the field of aluminum piston blank casting equipment, and can solve problems such as enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

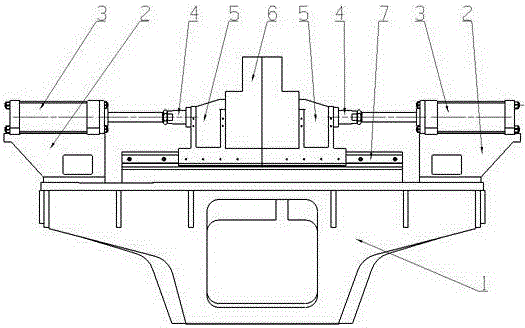

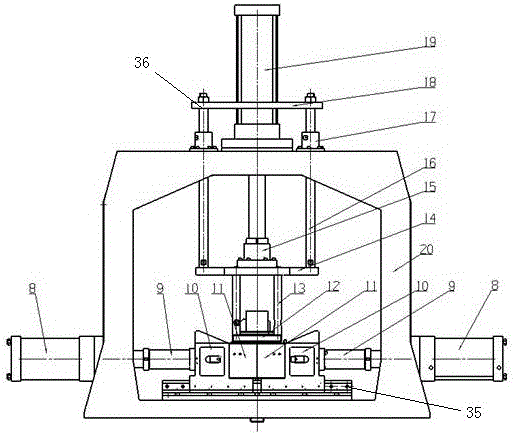

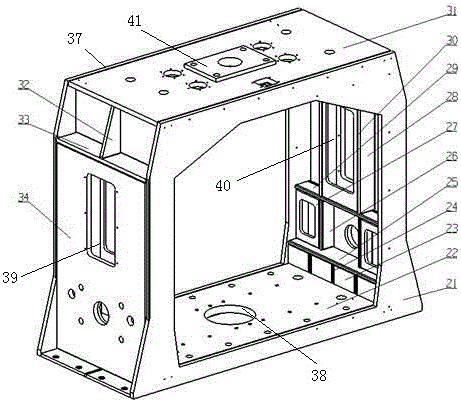

[0021] The high-rigidity frame bed for an aluminum piston blank casting machine of the present invention comprises a frame bed 20, and an outer mold opening and closing device and a top mold opening and closing device installed on the frame bed, and the outer mold opening and closing device laterally drives the outer mold to open The top mold opening and closing device vertically drives the top mold to open and close; the outer mold opening and closing device includes two outer mold oil cylinders 8 symmetrically fixed on the left and right sides of the frame bed, each outer mold oil cylinder is connected with half of the outer mold 11, and the outer mold The mold oil cylinder drives the left and right halves of the outer molds to move horizontally to join or separate; the top mold opening and closing device includes a top mold cylinder 19 fixed on the top of the frame bed, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com