Optical element achieving axial uniform linear focal spots

An optical device and uniform line technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of complex optical system, limited focal depth range, and large influence on material surface, and overcome the problems of low peak power, low The effect of overcoming the limited range of depth of focus and overcoming complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings.

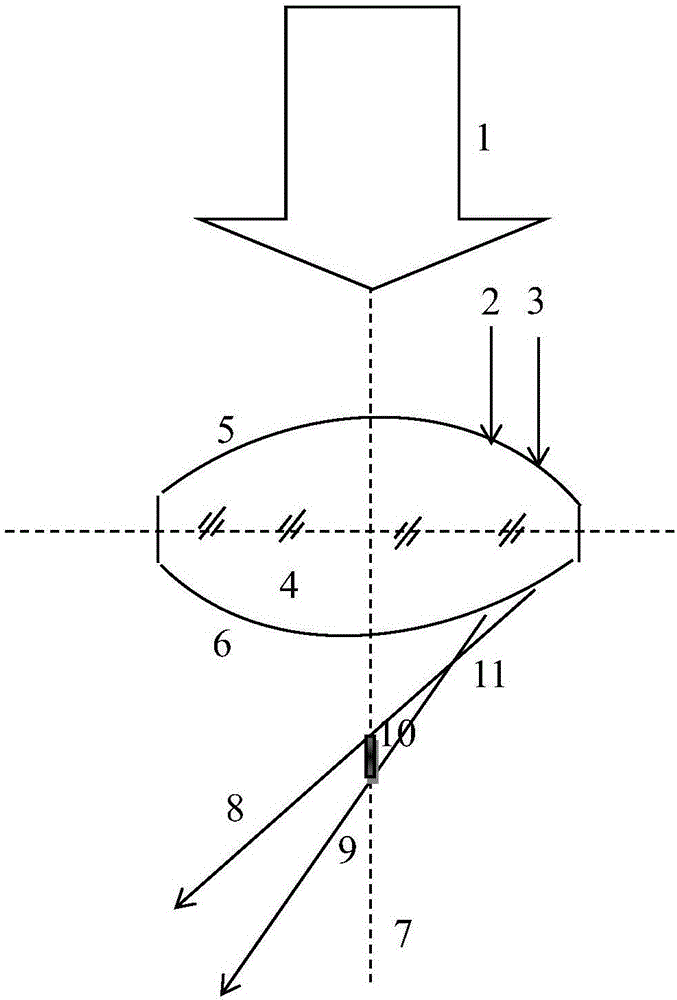

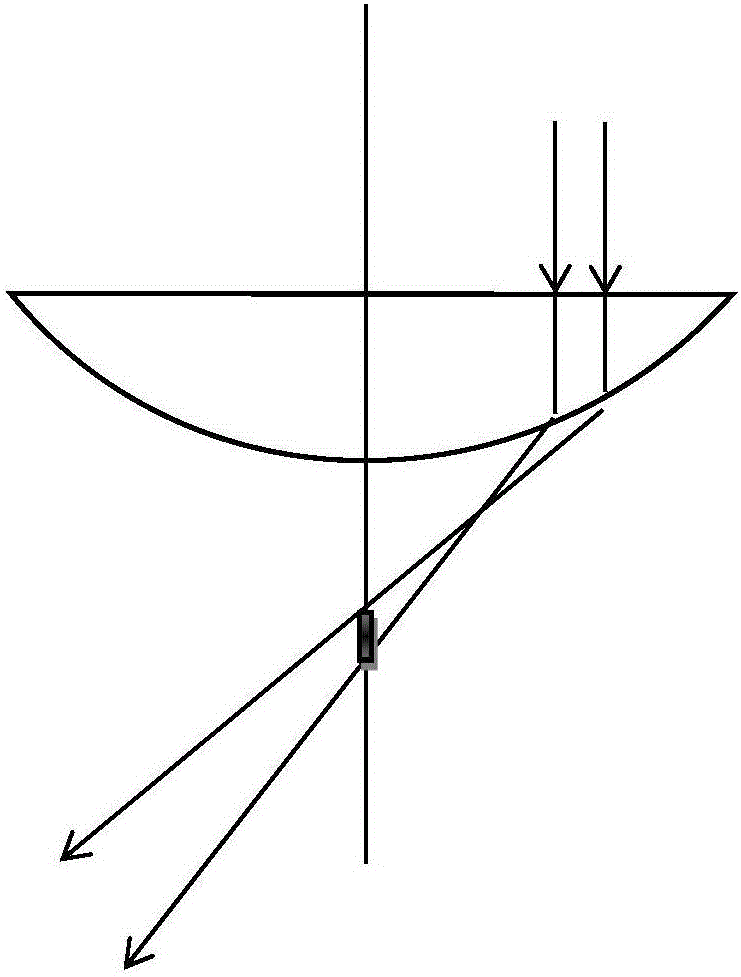

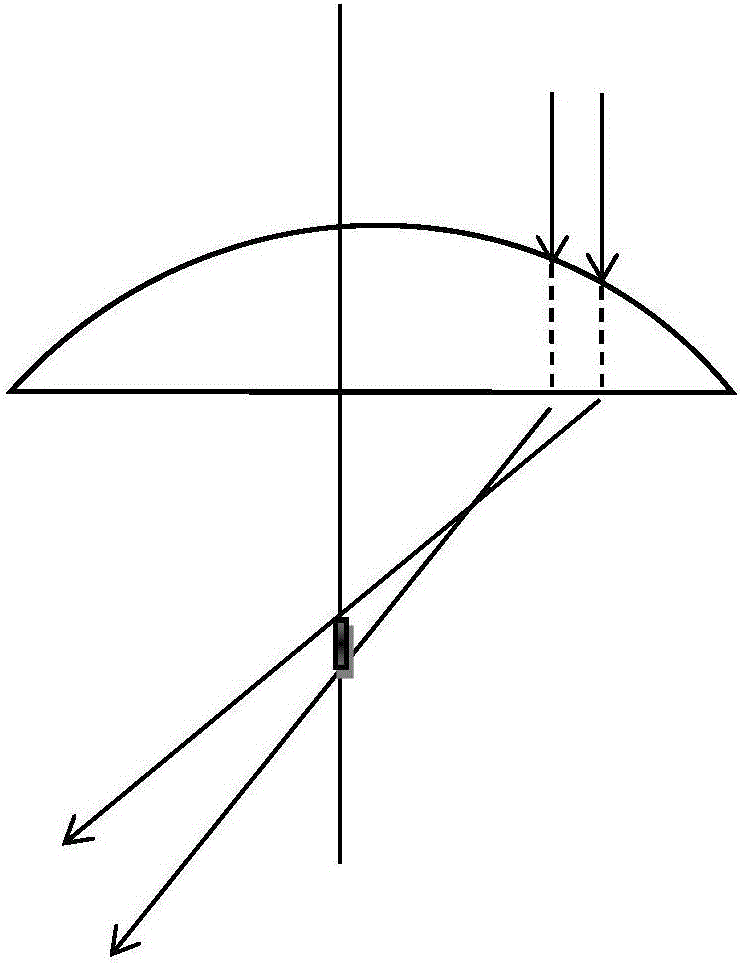

[0023] Such as figure 1 As shown, the present invention is a lens 4, which is characterized in that: the incident surface and the outgoing surface of the lens are both curved surfaces, and the incident light of any lateral distribution presents a uniform linear focus on the optical axis of the lens after being focused by the lens. spot. The lens 4 of the present invention is made of any optical material suitable for high-power laser transmission, and its incident surface 5 and outgoing surface 6 are curved surfaces, and the curved surfaces are aspherical. The laser beam 1 with any lateral distribution converges toward the optical axis 7 through the lens 4. In the laser beam 1, the ring composed of the inner circle ray 2 and the outer circle ray 3 passes through the optical lens 4 to produce refracted rays 9 and 8, and form a light beam paragraph 10. Refracted rays 8 and 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com