Auxiliary clamping device for turning steam turbine rotor on horizontal lathe

A steam turbine rotor and auxiliary clamping technology, which is applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of secondary injury to personnel and equipment, indentation on the finished surface of the rotor, and shaft channeling of copper gaskets, etc. Achieve the effect of avoiding the hidden danger of loosening, low cost and easy production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

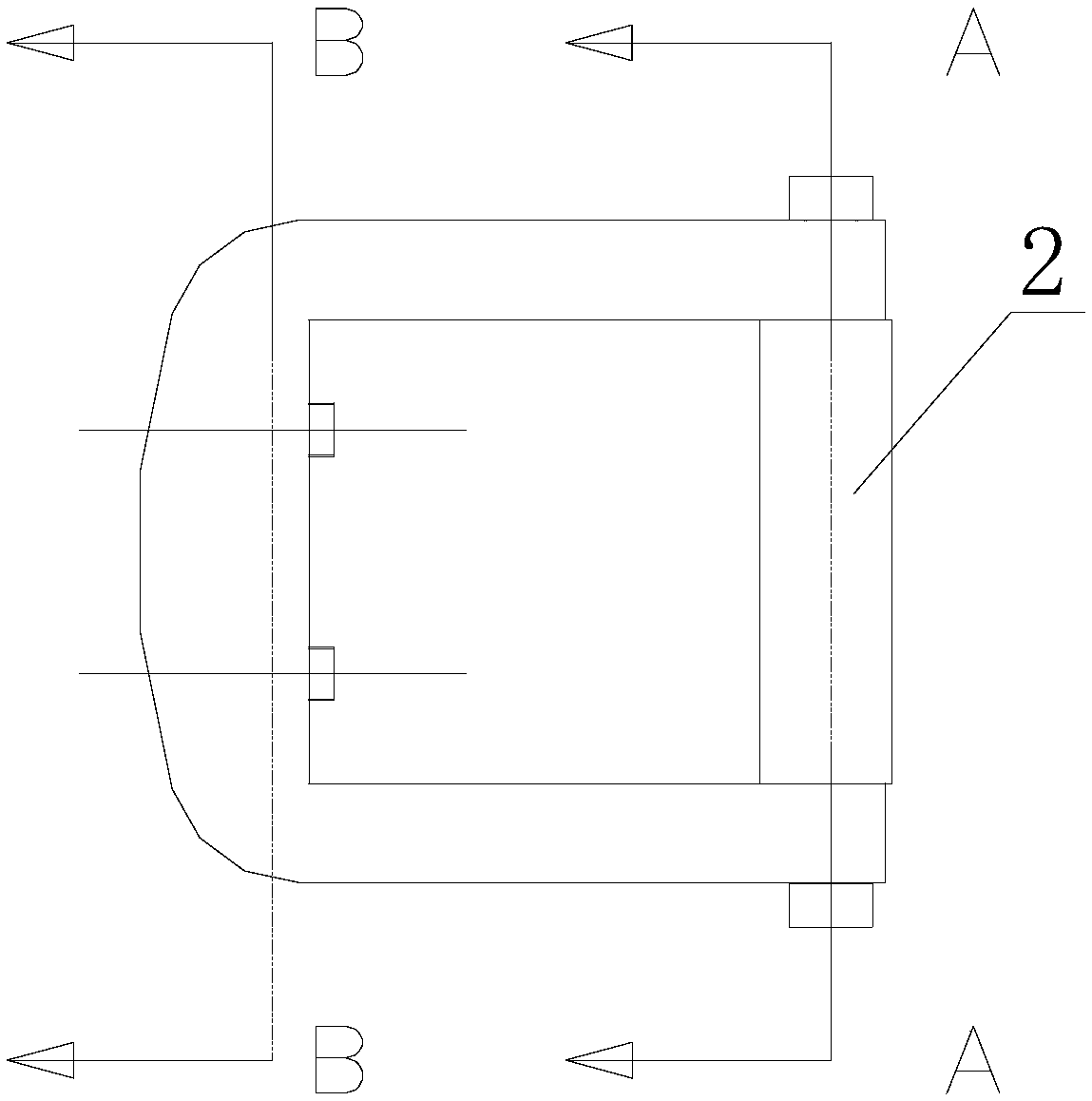

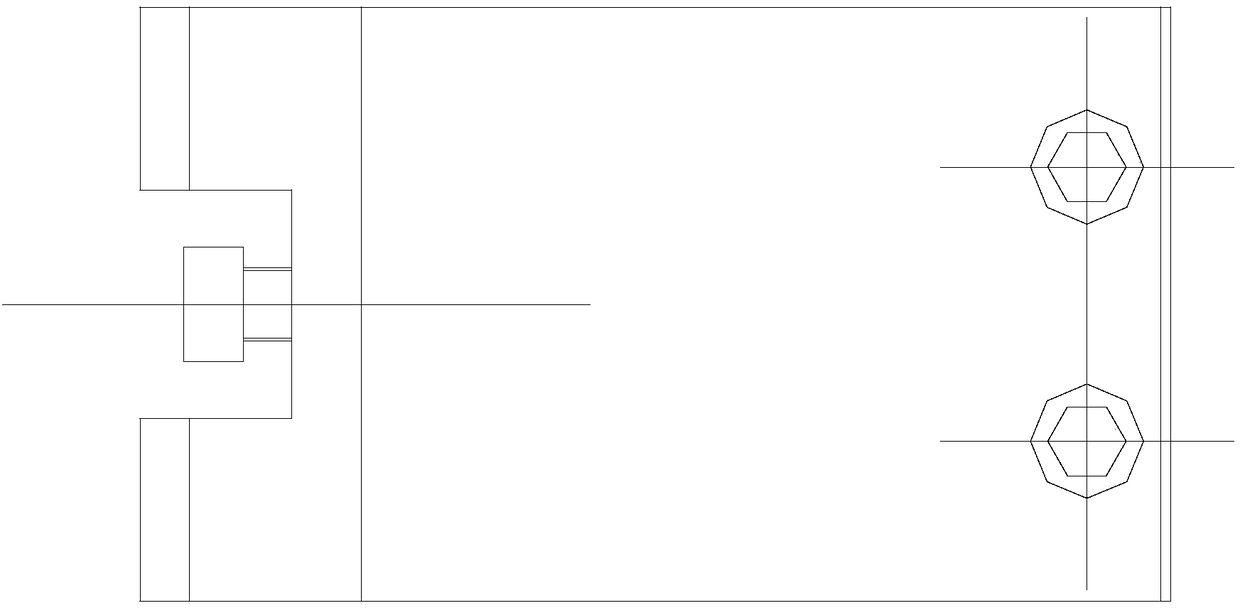

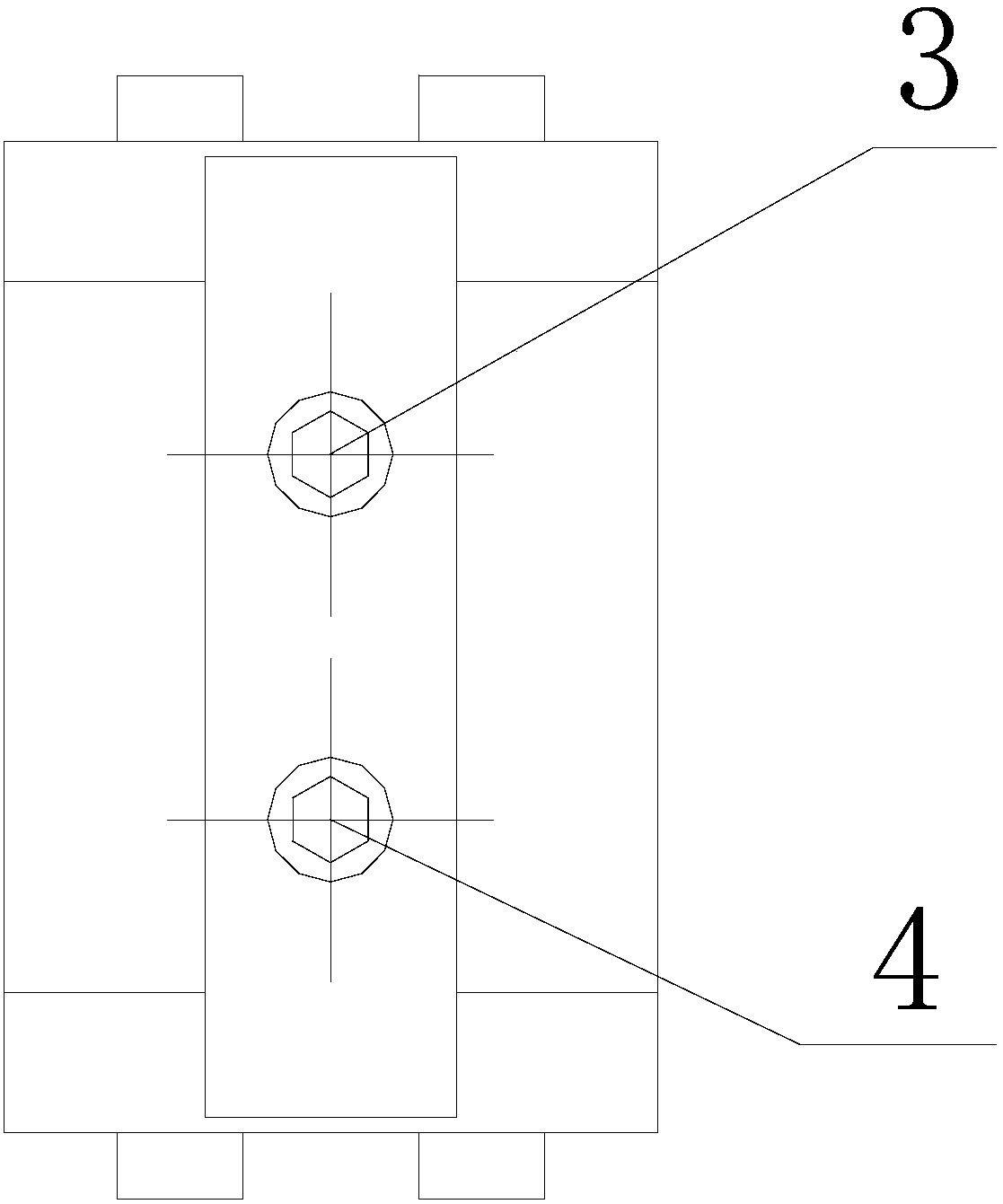

[0024] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, this embodiment horizontal lathe turning steam turbine rotor auxiliary clamping device, this device consists of U-shaped plate 1, cuboid copper gasket 2, first bolt 3, second bolt 4, third bolt 5, The fourth bolt 6, the fifth bolt 7 and the sixth bolt 8 are formed;

[0025] The cuboid copper gasket 2 is arranged in the opening of the U-shaped plate 1, and the inner surface of the U-shaped plate 1 and the inner surface of the rectangular parallelepiped copper gasket 2 are enclosed to form a cuboid hole; the rectangular parallelepiped copper gasket 2 and the inner surface of the U-shaped plate 1 Among the two contacting end faces, one of the end faces is provided with a first threaded blind hole 21 and a second threaded blind hole 22, and the other end face is provided with a third threaded blind hole 23 and a fourth threaded blind hole 24; The connecting line of the center of the blind hole ...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Image 6 This embodiment is described. The difference between this embodiment and the first embodiment is that the nut of the fifth bolt 7 and the nut of the sixth bolt 8 are arranged inside the elongated notch 11 . Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first or second embodiment is that the screw head of the fifth bolt 7 protrudes outside the first threaded through hole 13 . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com