vehicle stabilizer bar assembly

A stabilizer bar and assembly technology, applied in the field of auto parts, can solve the problems of expensive hollow stabilizer bar material, unfavorable vehicle lightweight design, heavy stabilizer bar quality, etc., to achieve easy design and implementation, good stability and practicability, The effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

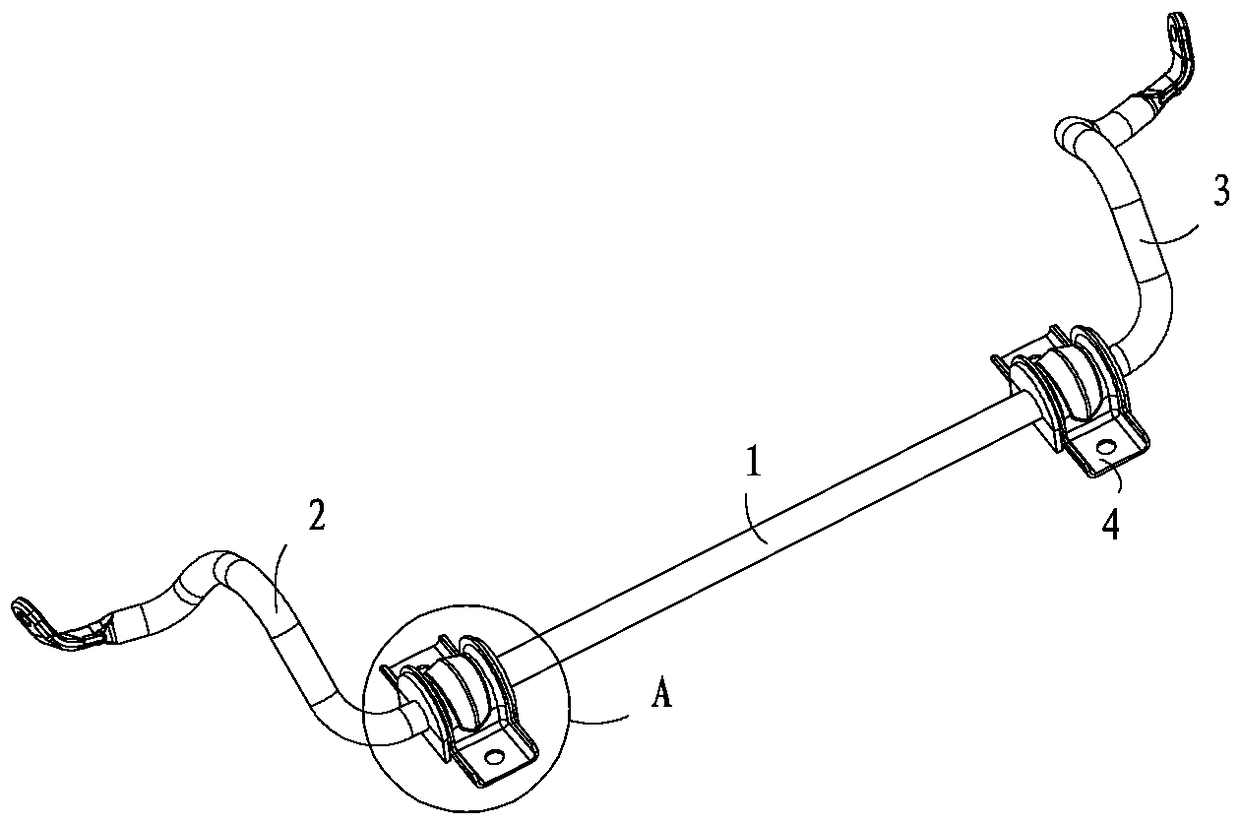

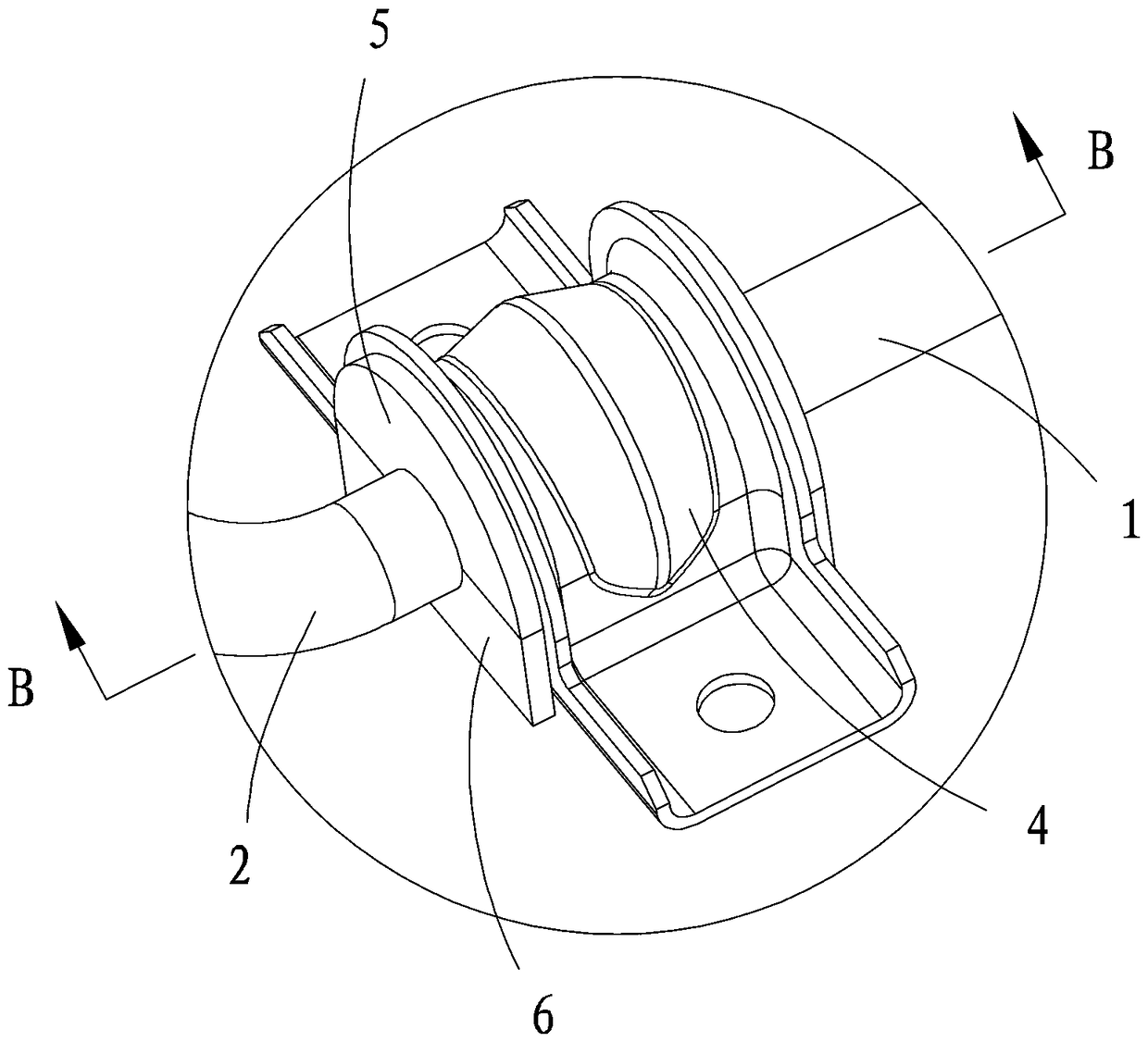

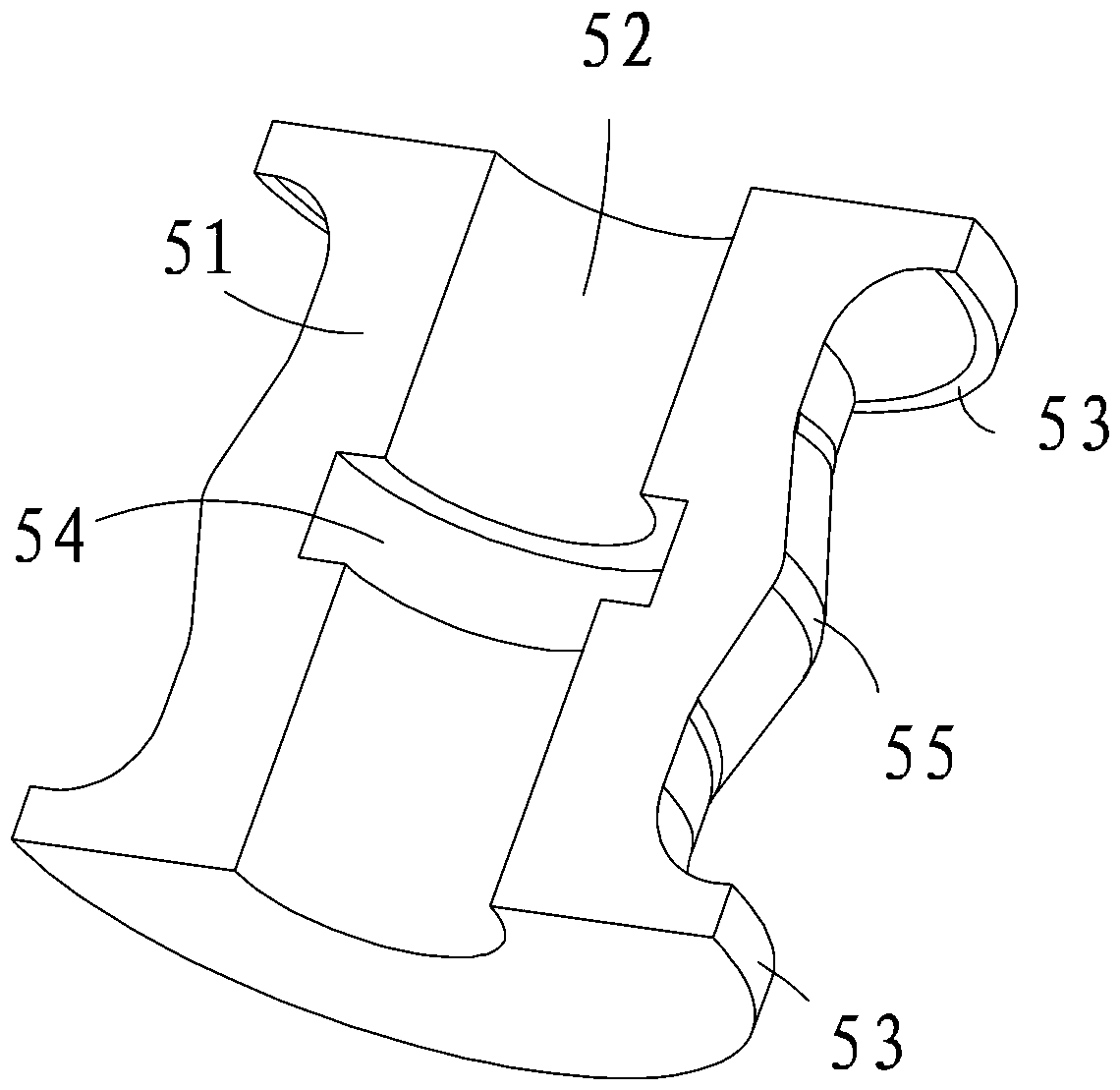

[0038] The invention relates to a vehicle stabilizer bar assembly, which includes a stabilizer bar body composed of a rod body and longitudinal arms symmetrically connected to two ends of the rod body, and an outwardly convex limiting portion is configured at the joint between the longitudinal arm and the rod body. The vehicle stabilizer bar assembly also includes a bushing fitted on the stabilizer bar body by fitting with the aforementioned limiting portion, and a stabilizer bar bracket clamped on the bushing. The vehicle stabilizer bar assembly constructs a protruding limiting portion on the stabilizer bar body, and inserts the bushing on the limiting portion. The integral structure of the limiting portion and the stabilizer bar body can avoid Disadvantages caused by installing retaining rings or clamps on the stabilizer bar body, and can also increase the contact area between the bushing and the stabilizer bar body, which is beneficial to improve the torsional stiffness of t...

Embodiment 2

[0048] This embodiment relates to a vehicle stabilizer bar assembly, which has substantially the same structure as that of the vehicle stabilizer bar assembly in Embodiment 1, except that Figure 8 As shown in , the limiting portion formed on the main body of the stabilizer bar in this embodiment is a rod body protrusion formed at the end of the rod body 1 , and the rod body protrusion can be formed at the end of the rod body 1 through a crimping process. At the end of the left trailing arm 2 there is also an embedded portion with the same outer diameter as the inner diameter of the rod body 1 , and the embedded portion can be formed at the end of the left trailing arm 2 by turning and milling. When the vehicle stabilizer bar assembly is assembled, the embedded part of the end of the left trailing arm 2 is embedded in the rod body 1, and the left trailing arm 2 and the rod body 1 are welded together, and then the groove on the bushing is aligned with the end of the rod body 1. ...

Embodiment 3

[0050] This embodiment relates to a vehicle stabilizer bar assembly, which has substantially the same structure as that of the vehicle stabilizer bar assembly in Embodiment 1, except that Figure 9 As shown in , the limit part formed on the main body of the stabilizer bar in this embodiment is a snap ring 7 snapped on the end of the rod body 1, and an outer diameter and an inner diameter of the rod body 1 are also formed at the end of the left longitudinal arm 2 The same embedded part, which can be formed at the end of the left trailing arm 2 by turning and milling process. When the vehicle stabilizer bar assembly is assembled, the embedded part at the end of the left trailing arm 2 is embedded in the rod body 1, and the left trailing arm 2, the rod body 1 and the snap ring 7 are welded together, and then the groove on the bush is aligned with the rod body The snap ring 7 at the end of 1 can be embedded and fitted. The above is an example of the limiting part on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com