Stacking platform of stacking production line for bagged cargoes

A technology of production line and loading platform, which is applied in the direction of object stacking, packaging, packaging machines, etc. It can solve the problems of uneven stacking of bagged goods, easy to generate noise, and easy to shake, etc., and achieve good quality and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

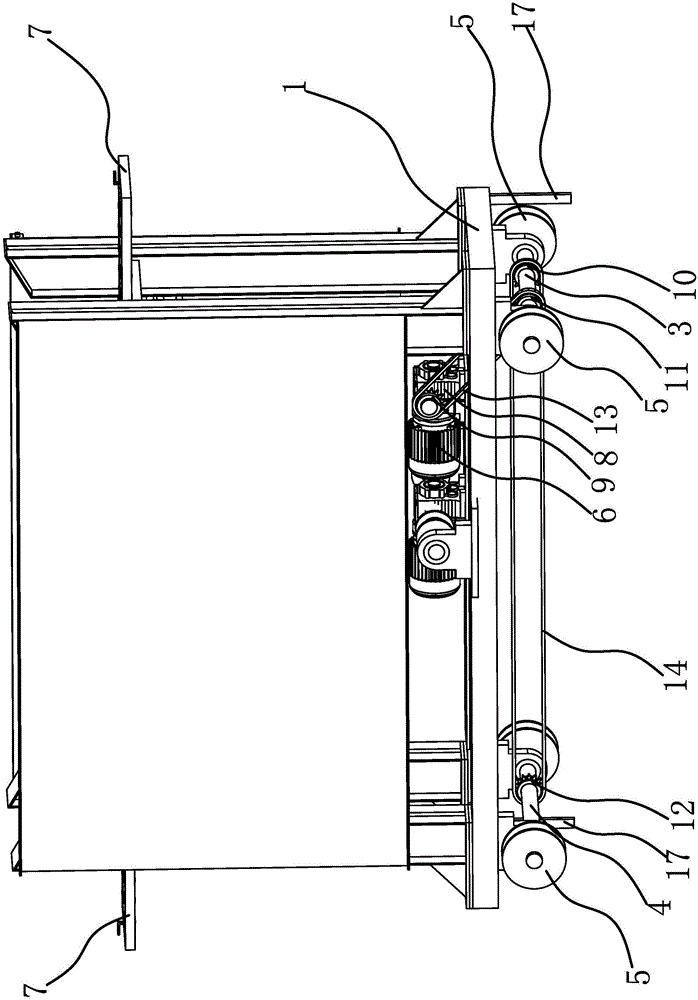

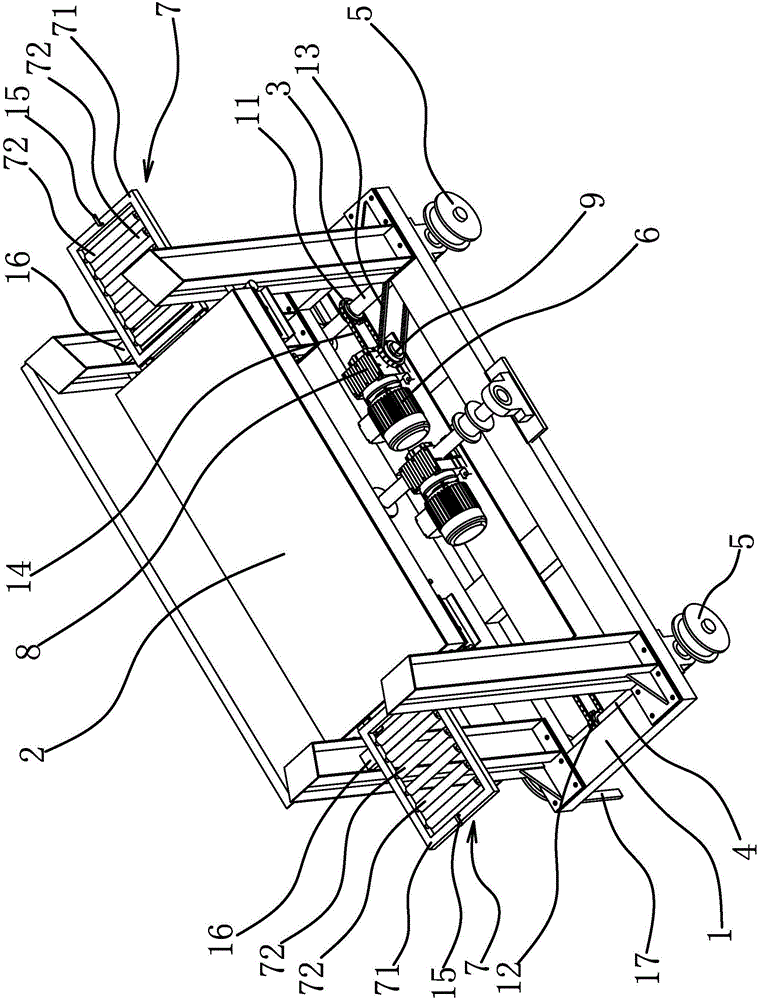

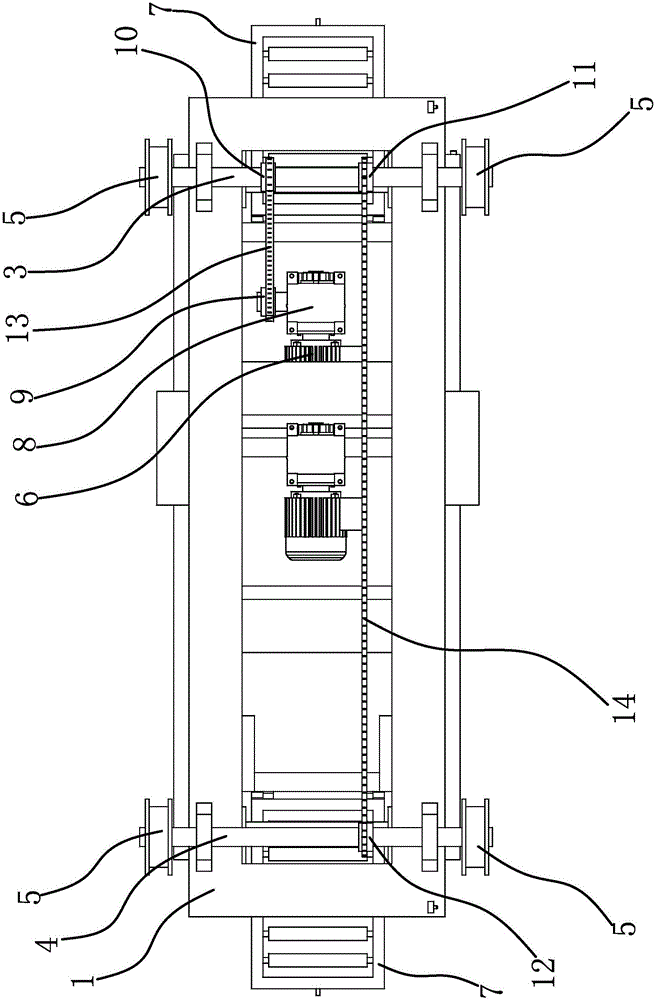

[0025] The stacking loading platform of this stacking production line for bagged goods includes a vehicle frame 1, a stacking platform 2, a drive shaft 3, a drive shaft 2 4, a roller 5, a drive motor 6, a supporting splint 7, a frame body 71, and a roller 72. Gearbox 8, driving wheel 9, driven wheel one 10, driven wheel two 11, driven wheel three 12, chain one 13, chain two 14, hook 15, guide bar 16, sensor mounting frame 17, photoelectric sensor 18, Touch sensor 19.

[0026] Specifically, as figure 1 , figure 2 with image 3 As shown, the stacking platform of the bagged goods stacking production line includes a vehicle frame 1 and a stacking platform 2 that is arranged in the vehicle frame 1 and can be lifted up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com