Automatic covering and packaging machine for carton box

An automatic buckle and packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to automatically buckle the carton cover, unable to operate continuously, and low work efficiency, saving manpower and time, and simple structure. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

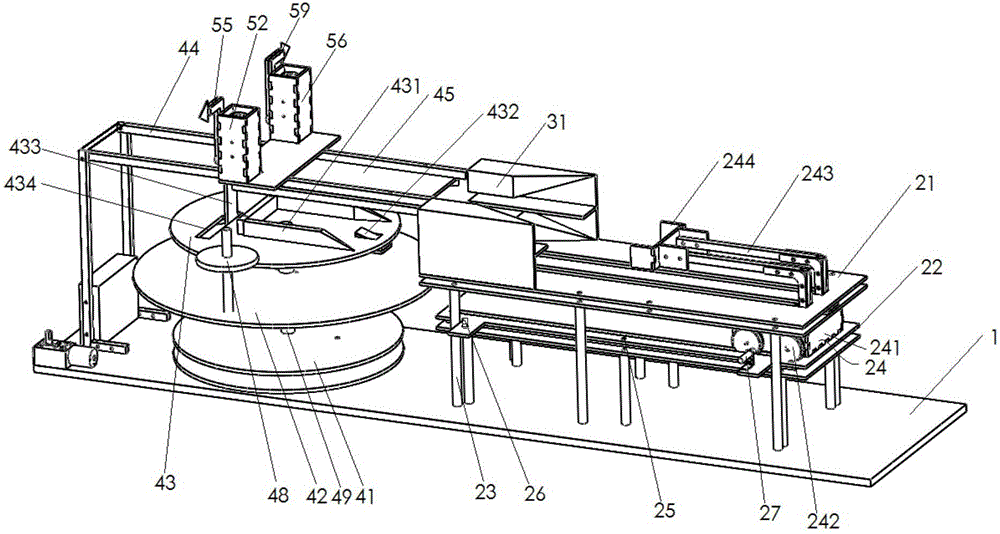

[0022] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

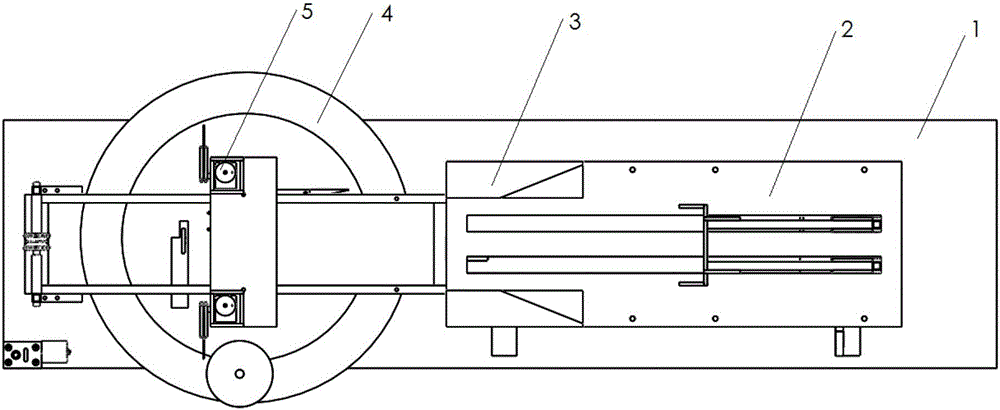

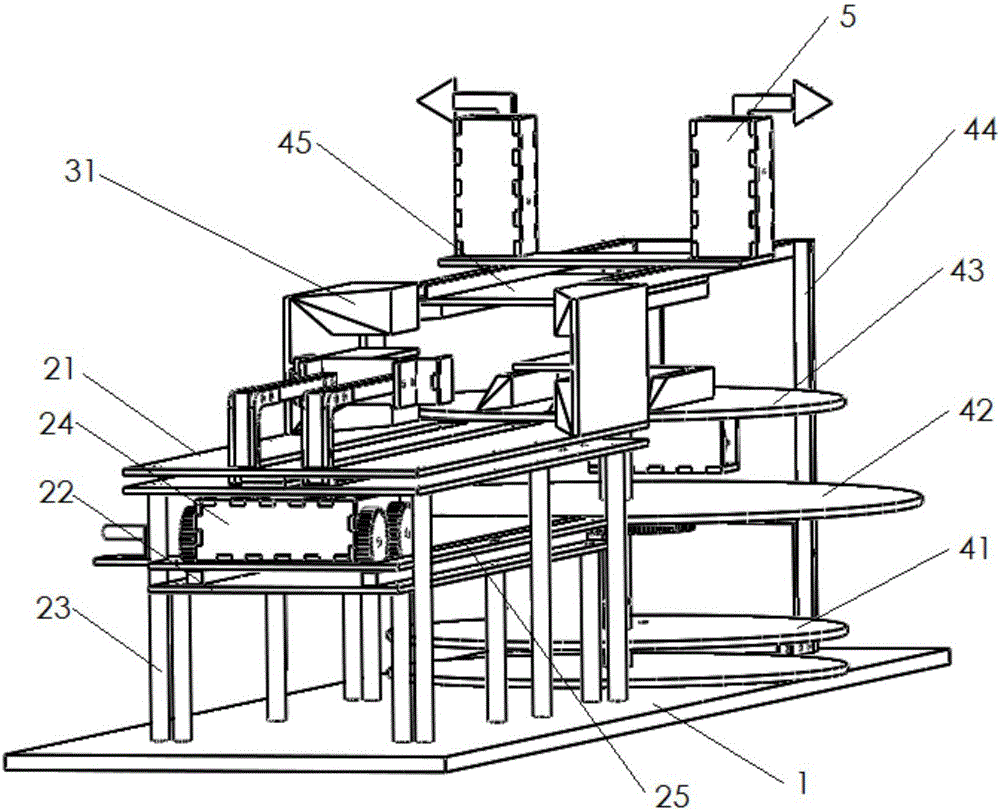

[0023] Such as Figure 1-Figure 6 , a kind of carton automatic buckle cover, sealing machine, comprise base plate 1, according to the sequence of work, the base plate is successively provided with carton box pushing device 2, box folding mechanism 3, sealing mechanism 4 and cutting mechanism 5;

[0024] The carton pushing box device 2 includes a pushing platform and a pushing box trolley 24. The pushing platform includes an upper deck 21 and a lower deck 22, and the upper deck 21 and the lower deck 22 are fixed on the base plate 1 by a column 23. Between upper floor platen 21 and lower floor platen 22, be provided with push box dolly 24, be provided with rack as dolly track 25 on lower floor platen 22, push box dolly 24 comprise car body 241, push rod 243, wheel 242, car body 241 is equipped with a dolly drive motor, and the push rod 243 is positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com