Fixing frame for glass transportation

A fixed frame and glass technology, applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of scratches, glass breakage, insufficient protection of glass plate damage, etc., and achieve the effect of reducing damage and avoiding impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

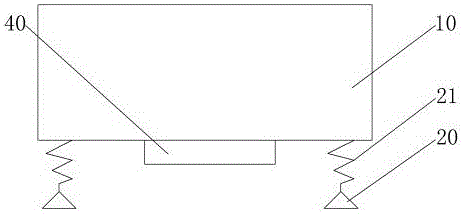

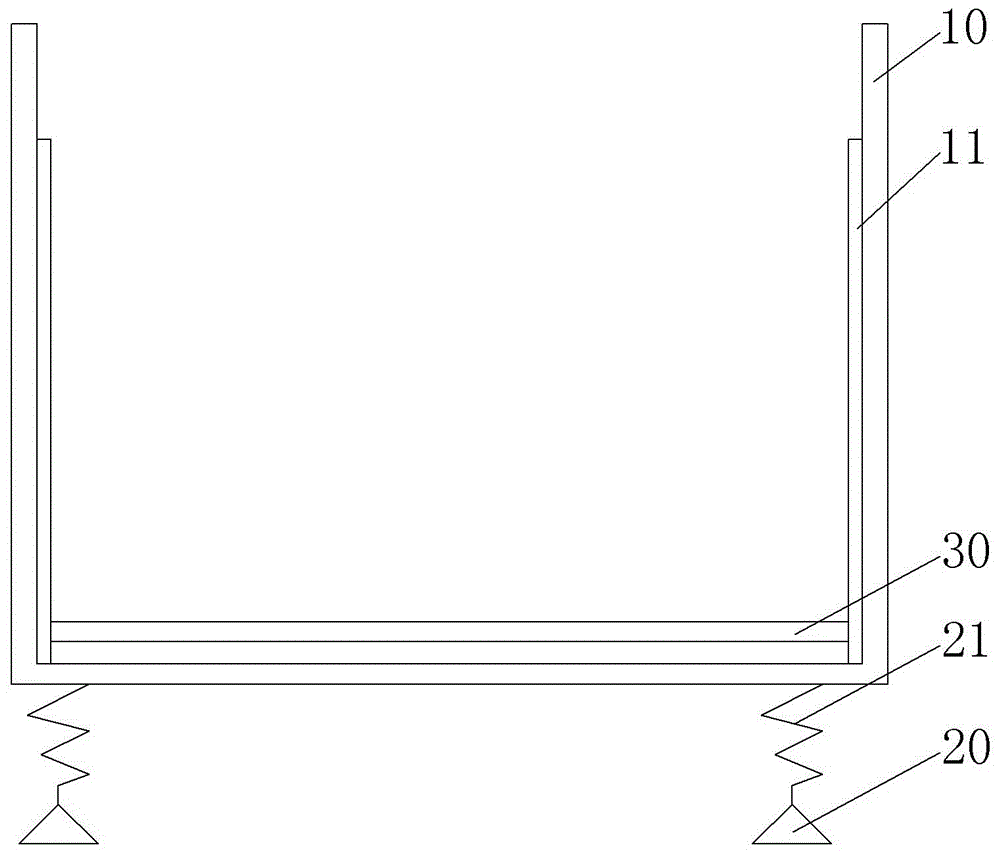

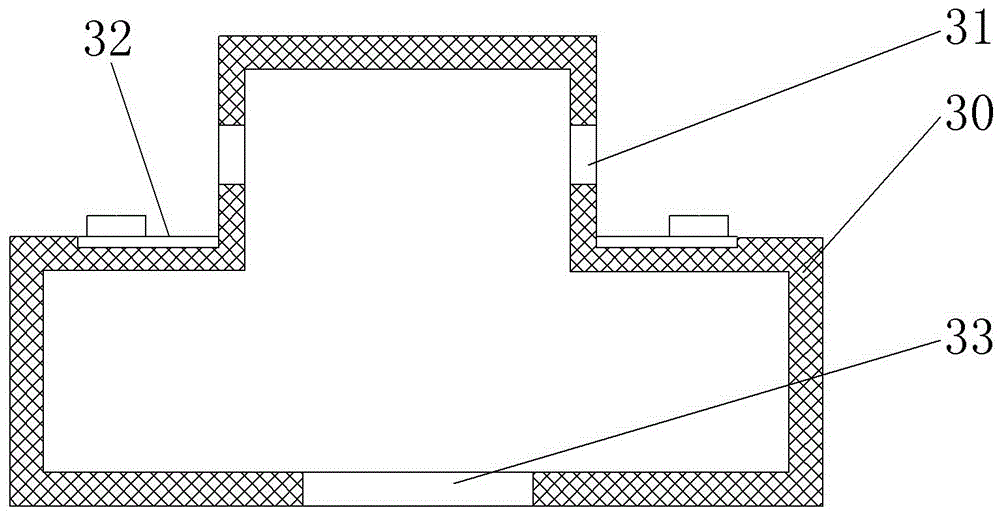

[0016] The reference signs in the accompanying drawings include: U-shaped frame 10 , rubber layer 11 , first spring 21 , suction cup 20 , rubber fixing strip 30 , suction port 31 , guide plate 32 , air outlet 33 , and vacuum pump 40 .

[0017] The embodiment is basically as attached Figure 1-3 Shown: a fixed frame for glass transportation, which includes a U-shaped frame 10, a rubber layer 11, a rubber fixing strip 30, a vacuum pump 40, and a suction cup 20, wherein the two ends and the top of the U-shaped frame 10 along the length direction are open, and the rubber The layer 11 is laid on the two inner sidewalls of the U-shaped frame 10 and several guide grooves are vertically arranged on it, and the rubber fixing strips 30 are several and are located at the inner bottom of the U-shaped frame 10 along the length direction of the U-shaped frame 10 distribution, the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com