Wind grid device and method for cooling hyperbolic curved tempered glass by using same

A wind grille and grid technology, applied in the field of double-curved tempered glass production, can solve the problem that the shape of the double-curved glass on the air outlet surface is very different, reduce the yield of double-curved tempered glass, and the heat of the double-curved tempered glass is not good. Equal problem, to achieve the effect of speeding up the transfer rate of cold and heat, shortening the replacement time and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

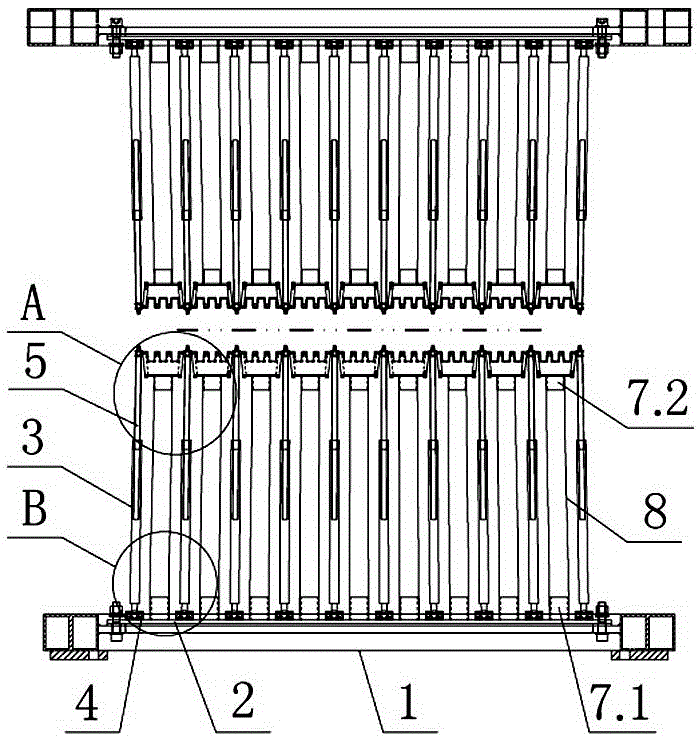

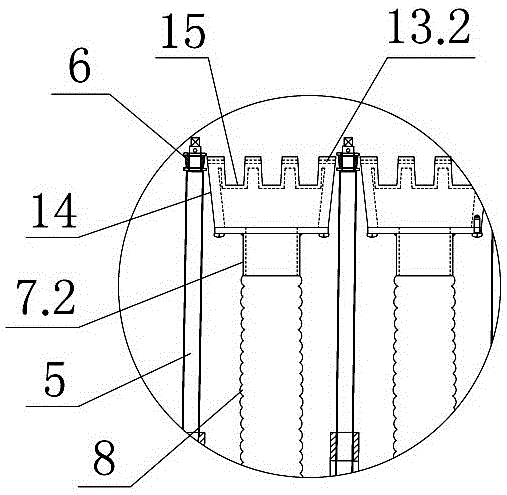

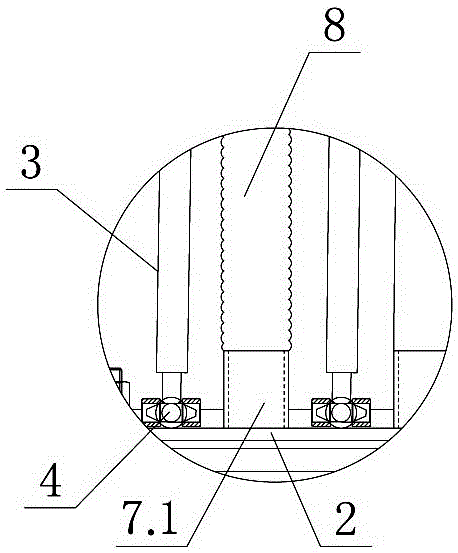

[0036] Such as figure 1 As shown, the air grid device of the present invention includes an upper air grid and a lower air grid that are arranged symmetrically at intervals above and below and have the same structure. The inside of the air outlet plate 2 is provided with a cavity communicating with the external air duct system, and 42 height adjustment units arranged in six rows and seven columns with the same structure are arranged on the surface of the air outlet plate 2: the height of the present invention The adjustment unit includes an adjusting screw sleeve 3 arranged vertically. The lower end of the adjusting screw sleeve 3 is hinged with the air outlet plate 2 through a hinge 4. The upper end of the adjusting screw sleeve 3 is screwed with an adjusting screw 5. The top of the adjusting screw 5 is set There are connecting blocks 6, and correspondingly, the connecting blocks 6 are also arranged in six rows and seven columns (of course, according to actual needs, the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com