Collagen spray drying device

A collagen and drying device technology, applied in the direction of animal/human protein, peptide preparation method, connective tissue peptide, etc., can solve the problem of affecting the efficiency of evacuation, fan service life, reducing collagen drying yield, collagen adhesion, etc. problem, to achieve the effect of guaranteed service life, convenient cleaning, and improved sticking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

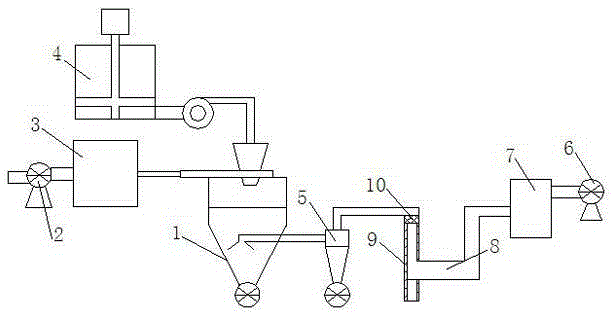

[0016] The present invention comprises centrifugal spray tower 1, and described centrifugal spray tower 1 passes hot gas into it by air blower 2, heater 3, and collagen protein is passed into centrifugal spray tower 1 through hopper 4; Described centrifugal spray tower 1 passes cyclone The separator 5 is connected to an induced fan 6, and a bag filter 7 is arranged between the induced fan 6 and the cyclone separator 5.

[0017] The bag filter 7 and the induced draft fan 6 are connected by a U-shaped pipe 8, and openings are provided at the corners of the vertical and horizontal parts of the U-shaped pipe 8, and a vertically arranged pipe 9 is provided to extend into the opening Inside, the upper part of the pipe 9 is provided with a filter ring 10, and the pipe 9 extends into the U-shaped pipe 8 so that the filter ring 10 is located at the longitudinal part of the U-shaped pipe 8, and the pipe 9 is located at the joint of the longitudinal part and the transverse part of the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com