A polycar carboxylic acid system polymer water reduction agent and its preparation method

A polycarboxylic acid series and polymer technology, which is applied in the field of polycarboxylate polymer water reducing agent and its preparation, water reducing agent and its preparation field, can solve the problem of late start of research on polycarboxylate water reducing agent, etc. Conducive to industrialization and application, simple production process, strong steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

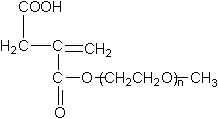

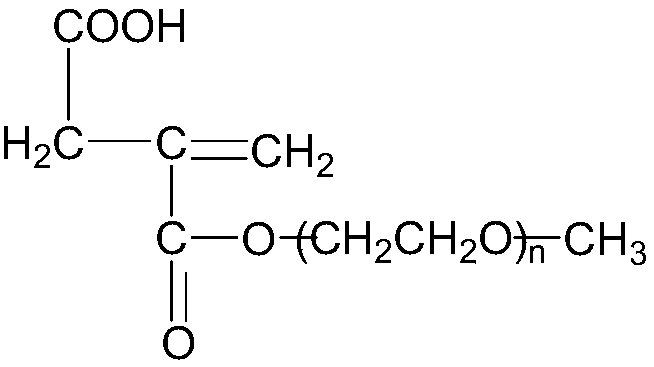

Method used

Image

Examples

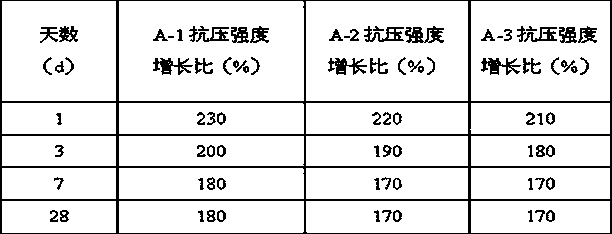

Embodiment 1

[0027] Molar ratio: N-[4-(sulfonamide)phenyl]acrylamide:polyethylene glycol monomethyl ether itaconate (n=20-30):polyethylene glycol monomethyl ether methacrylate (m= 20-30)=1.0:1.2:1.2 Prepare the raw materials. The above raw materials and the initiator ammonium persulfate are diluted with deionized water to form an aqueous solution with a mass concentration of 32%. In the reaction kettle equipped with electric stirrer, condenser, thermometer and water bath heating conditions, add polyethylene glycol monomethyl ether itaconate and N-[4-(sulfonamide)phenyl ] acrylamide aqueous solution, stir and heat up to 70°C, add polyethylene glycol monomethyl ether methacrylate aqueous solution, then open the pear-shaped separatory funnel, add diluted ammonium persulfate aqueous solution to the reaction kettle dropwise, pass through before diluting Ammonium sulfate consumption is 0.5% of the total mass of the monomer. The drip control speed is completed within 2 hours. After dripping, ke...

Embodiment 2

[0030] Molar ratio: N-[4-(sulfonamide)phenyl]methacrylamide: polyethylene glycol monomethyl ether itaconate

[0031] (n= 30-40): Polyethylene glycol monomethyl ether methacrylate (m= 30-40)=1:1.3:1.2 Prepare the raw materials, the above raw materials and initiator potassium persulfate are separated with deionized water Diluted into an aqueous solution with a mass concentration of 35%. In the reaction kettle equipped with electric stirrer, condenser, thermometer and water bath heating conditions, add polyethylene glycol monomethyl ether itaconate and N-[4-(sulfonamide)phenyl ] methacrylamide aqueous solution, stir and heat up to 60 ° C, add polyethylene glycol monomethyl ether methacrylate aqueous solution, then open the pear-shaped separatory funnel, drop diluted potassium persulfate aqueous solution into the reaction kettle, dilute The amount of pre-persulfate potassium is 1% of the total mass of the monomer. The drip control speed is completed within 2 hours. After drippi...

Embodiment 3

[0034] Molar ratio: N-[4-(sulfonamide)phenyl]methacrylamide: polyethylene glycol monomethyl ether itaconate (m=30-40): allyl polyoxyethylene ether x = 30-40) = 1:0.9:1.2 Prepare the raw materials. The above raw materials and the initiator sodium persulfate are diluted with deionized water to form an aqueous solution with a mass concentration of 40%. In the reaction kettle equipped with electric stirrer, condenser, thermometer and water bath heating conditions, add polyethylene glycol monomethyl ether itaconate and N-[4-(sulfonamide)phenyl ] methacrylamide aqueous solution, stir and heat up to 90 ° C, add allyl polyoxyethylene ether aqueous solution, then open the pear-shaped separatory funnel, add the diluted sodium persulfate aqueous solution dropwise to the reaction kettle, and dilute the persulfuric acid before The amount of sodium is 3% of the total mass of the monomer. The drip control speed is completed within 2 hours. After dripping, keep the temperature and react for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com