An automated surface treatment workstation

A surface treatment and workstation technology, applied in the field of automated surface treatment workstations, can solve the problems of operator health damage, large equipment footprint, poor working environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

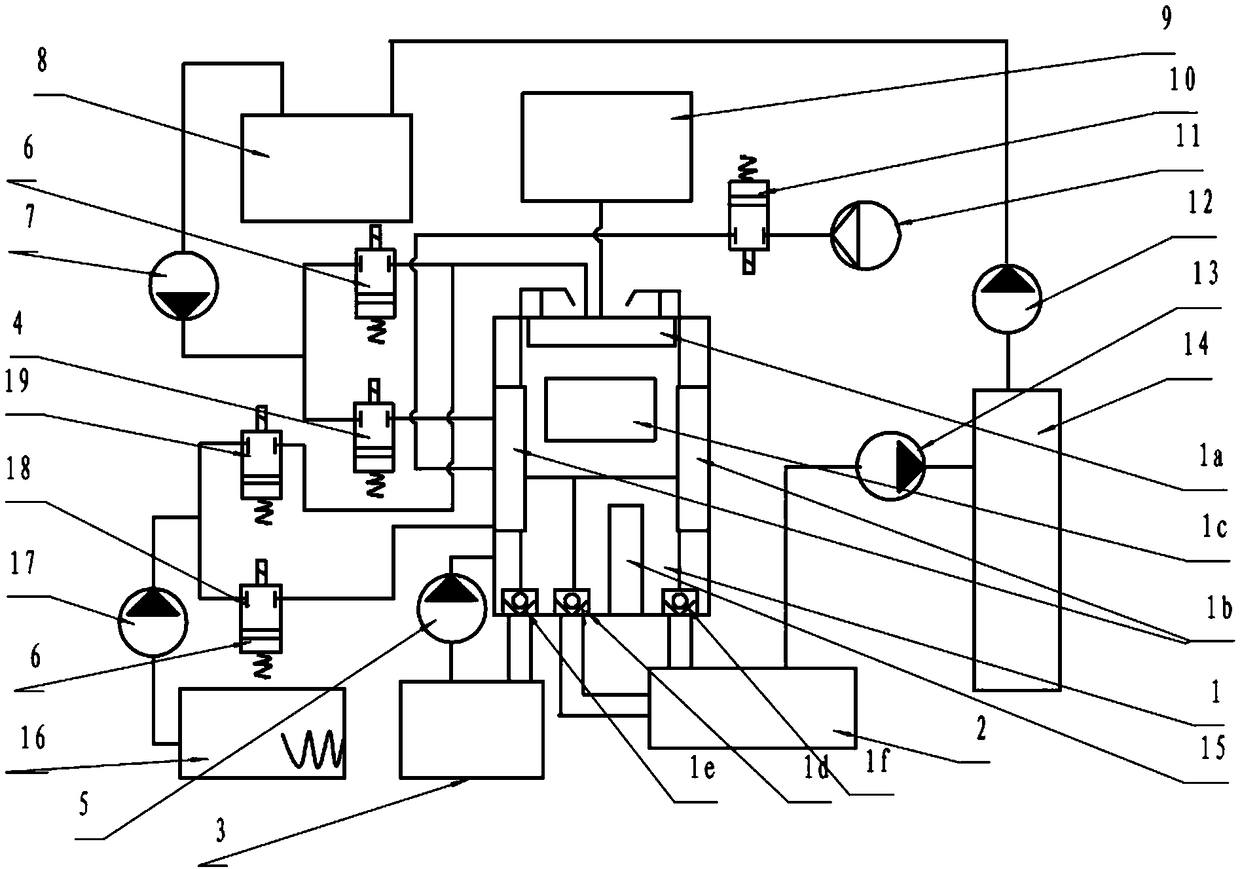

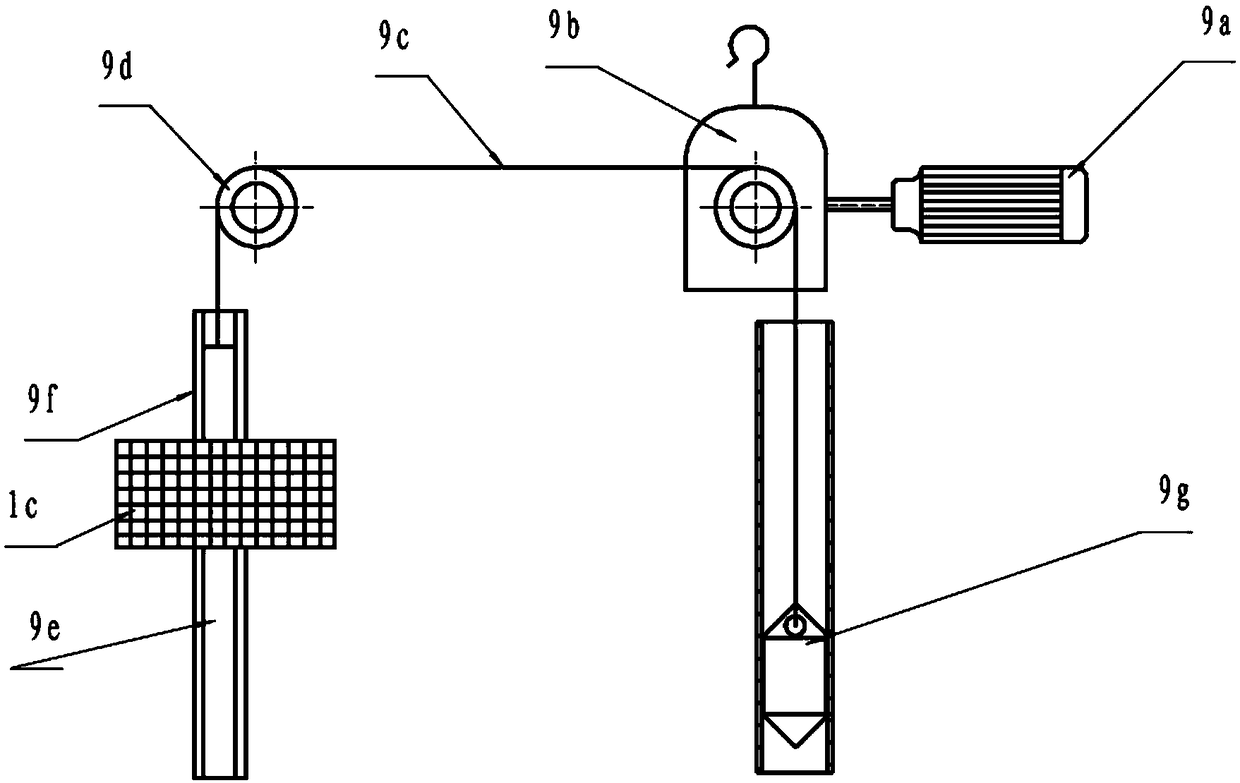

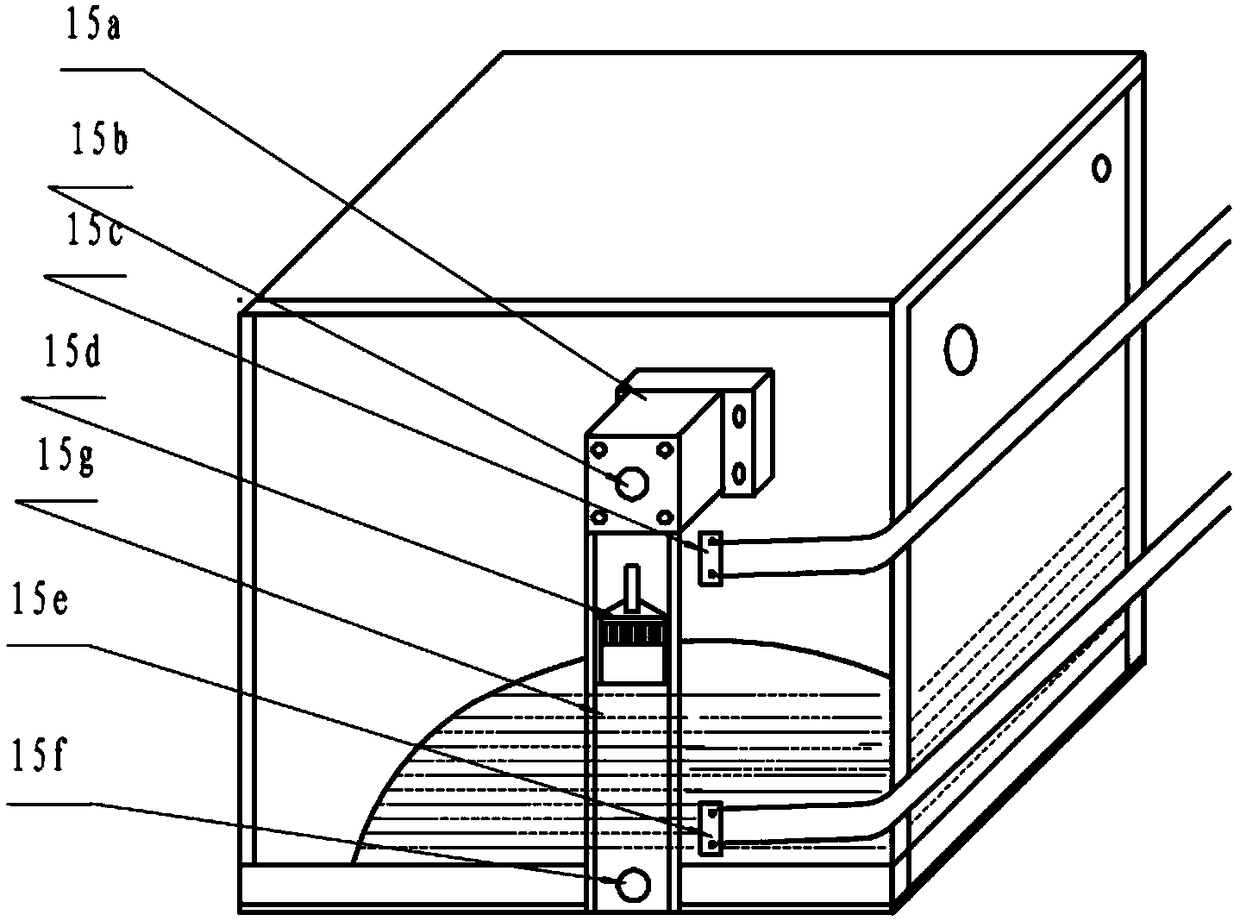

[0020] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

[0021] An automatic surface treatment workstation, including a working box 1, a sewage tank 2, a treatment liquid tank 3, a clean water tank 8, an electromechanical transmission device 9, a sewage processor 14, and a hot water tank 16. The working box 1 includes two The left and right spraying devices 1b on the side, the upper spraying device 1a arranged on the top of the working box 1, the parts hanger 1c is arranged under the upper spraying device 1a, the liquid level controller 15 is arranged on the outside of the working box 1, and the working box The bottom of 1 is provided with a left discharge valve 1e, a middle discharge valve 1d and a right discharge valve 1f, wherein the left discharge valve 1e communicates with the processing liquid tank 3, and the processing liquid tank 3 inputs the processing liquid into the In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com