Construction method for reducing damaged segments and offset deformation by small-radius curved shield tunneling

A technology of small radius curve and construction method, applied in mining equipment, earthwork drilling, vertical shaft equipment, etc., can solve the problems of line deformation, low efficiency, excessive deviation correction, etc., to reduce lateral force, technical safety and reliability, reduce negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

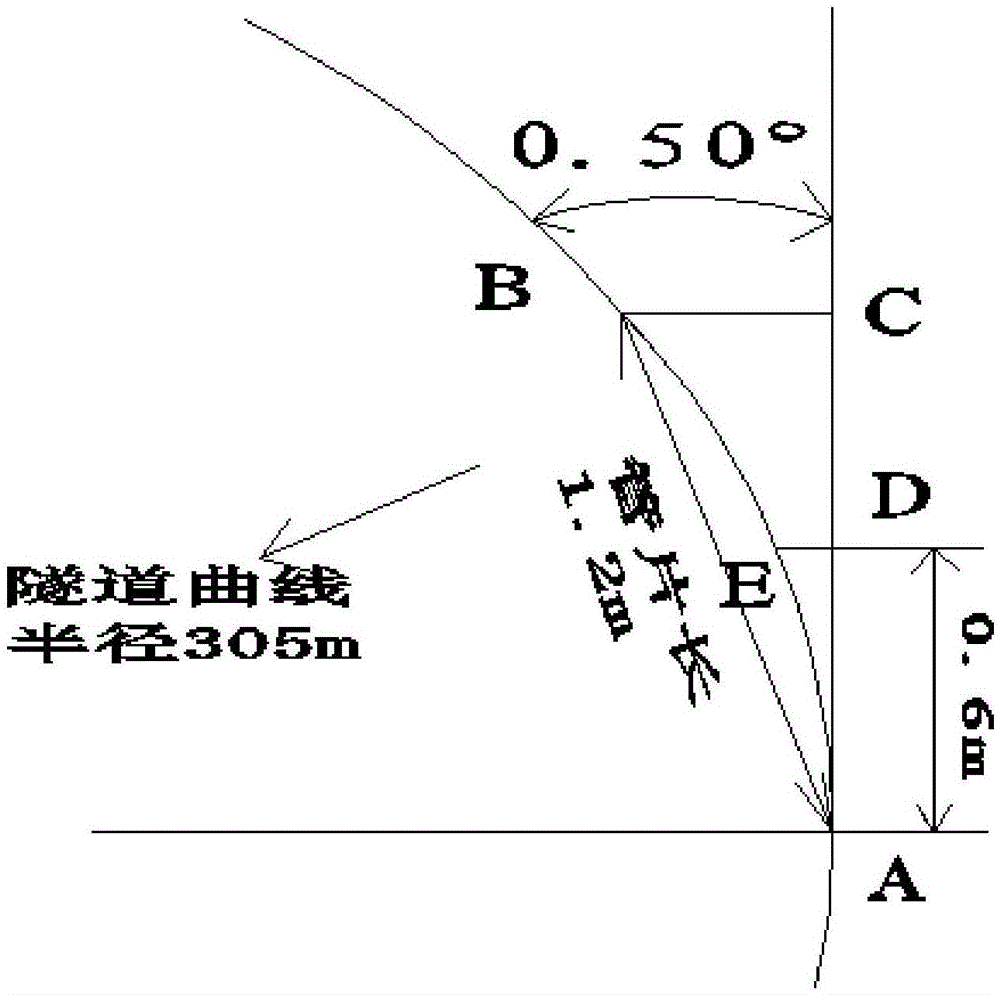

[0011] 1. Segment damage analysis of small radius curve segment

[0012] When the shield excavates on straight lines, transitional curves and large-radius curves, the shoe brace of the propulsion cylinder is usually not easy to crush the segment, but when the shield machine excavates on a curve section with a radius of R305m, the shoe brace of the propulsion cylinder The probability of destroying segments is much higher than other line segments. This is mainly because the gap between the shield tail and the segment of the small radius curve is too small, which causes the shield tail and the segment to get stuck and the segment has a large displacement under the action of the horizontal force component of the thrust, resulting in the gap between the jack and the segment, and between the segment and the segment. Line or surface contact between them will cause the segment to be damaged after being stressed. The following detailed analysis.

[0013] 1.1 The large displacement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com