Engine

An engine and wind-driven technology, which is applied in the direction of engine components, engine cooling, machine/engine, etc., can solve problems such as difficult to withstand high temperature, extremely high material requirements, and affect the thrust efficiency of aeroengines, so as to achieve high thrust efficiency and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

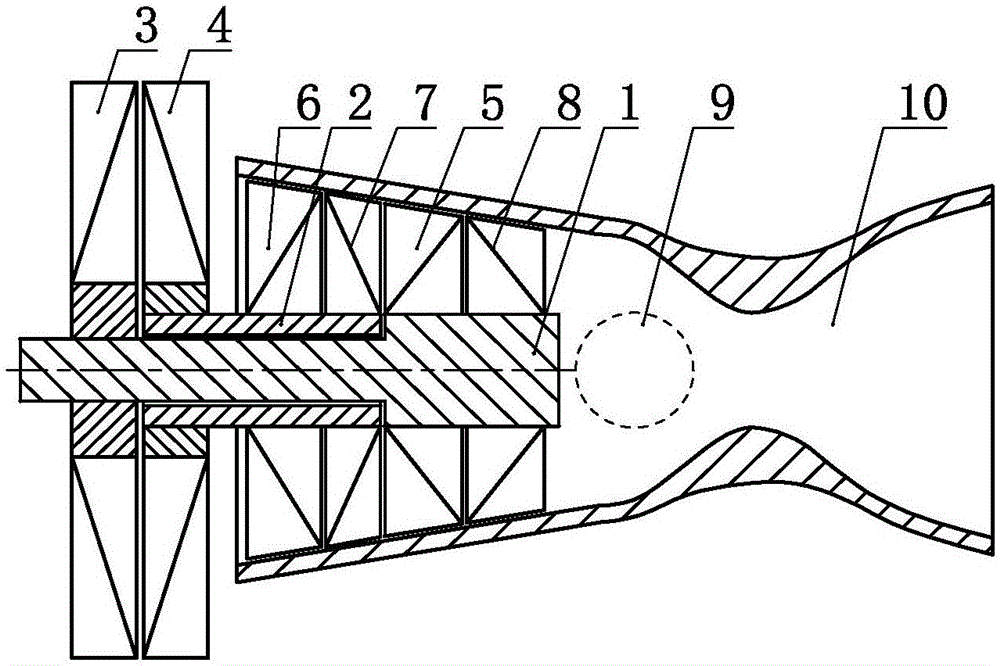

[0037] an engine such as figure 1 As shown, including power shaft A 1, power shaft B 2, wind turbine impeller A3, wind turbine impeller B 4, compressor impeller A 5, compressor impeller B 6, compressor impeller C 7, compressor impeller D 8, combustion chamber 9 and nozzle 10, the power shaft B 2 is sleeved outside the power shaft A 1, the compressor impeller A 5 is set on the power shaft A 1, and the wind turbine impeller A 3 is connected to the power shaft A 1. The power shaft A1 is set for transmission, the compressor impeller B6 is set on the power shaft B2, the wind turbine impeller B4 is set for transmission with the power shaft B2, and the compressor impeller C7 It is arranged on the power shaft B2, the compressor impeller D8 is arranged on the power shaft A1, the compressor impeller B6, the compressor C7, the compressor A5 and the compressor The impellers D 8 are sequentially connected in series, and the compressed gas outlet of the compressor impeller D 8 communicates...

Embodiment 2

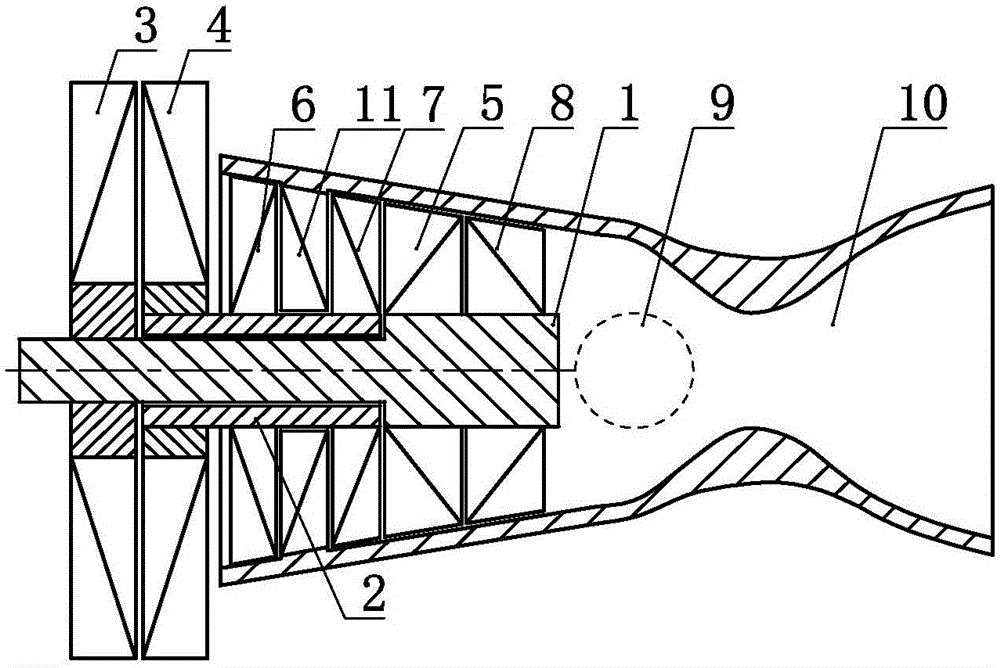

[0040] an engine such as figure 2 As shown, the difference from Embodiment 1 is that a stationary guide impeller 11 is provided between the compressor impeller B 6 and the compressor impeller C 7 .

[0041] As a transformable embodiment, embodiment 1 of the present invention and its transformable embodiment and embodiment 2 can further selectively select the wind turbine blade A 3 and the wind turbine blade B 4 Co-rotation setting or counter-rotation setting.

Embodiment 3

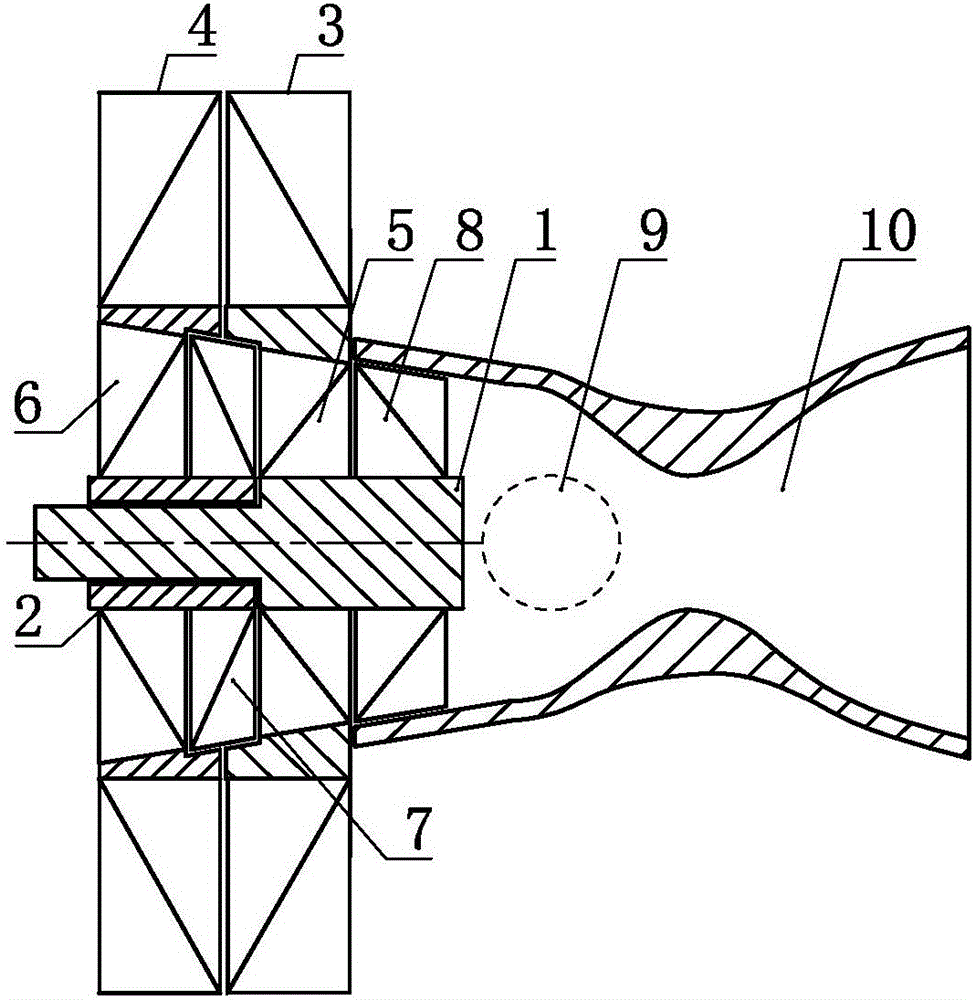

[0043] an engine such as image 3 As shown, including power shaft A 1, power shaft B 2, wind turbine impeller A3, wind turbine impeller B 4, compressor impeller A 5, compressor impeller B 6, compressor impeller C 7, compressor impeller D 8, combustion chamber 9 and nozzle 10, the power shaft B 2 is sleeved outside the power shaft A 1, the compressor impeller A 5 is set on the power shaft A 1, and the wind turbine impeller A 3 is connected to the power shaft A 1. The power shaft A1 is set for transmission, the compressor impeller B6 is arranged on the power shaft B2, the compressor impeller C7 is arranged on the power shaft B2, and the compressor impeller D8 is arranged on the On the power shaft A1, the compressed air impeller B6, the compressed air impeller C7, the compressed air impeller A5 and the compressed air impeller D8 are sequentially connected in series, and the compressed gas outlet of the compressed air impeller D8 passes through the The combustion chamber 9 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com