Manufacturing process of canned air

A production process and air canning technology, which are applied to fixed-capacity air storage tanks, container discharge methods, and equipment loaded into pressure vessels, etc., can solve the problems of air cans that have not passed sterilization and antivirus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

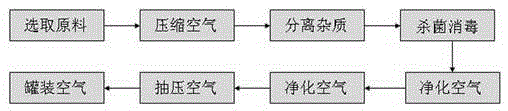

[0019] A manufacturing process of air cans, characterized in that: the alpine air is used as raw material to collect air→compress air→separate impurities→sterilize→purify air→pump→fill; the specific operating points and steps are:

[0020] (1) Raw material selection, select the fresh air from high mountains, and select the block with high negative oxygen ion content to collect the air through the detector.

[0021] (2) Compressed air is compressed into the air storage tank through an air compressor;

[0022] (3) Separating impurities, separating small particles such as moisture, pollen, and impurities in the air through the impurity separator;

[0023] (4) Sterilization: The air in the air storage tank enters the transparent tube, and is sterilized by the external alpine sunlight ultraviolet rays or artificial ultraviolet rays;

[0024] (5) Purify the air; the sterilized air enters the activated carbon adsorption container for secondary impurity removal and sterilization. Act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com