Splicing-type wall body structure with fireproof and purifying functions and preparation method

A wall structure, splicing technology, applied in the direction of fire prevention, walls, building components, etc., can solve the problems of no purification, flammability, not strong and reliable, save labor and cost, easy and simple installation, and reduce human fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of a spliced wall structure with fire prevention and purification functions, characterized in that the preparation method comprises the following steps:

[0036] (1) Take chromium slag and activated carbon separately, crush them into 3~10mm granular, and set aside;

[0037] (2) Take 10-15 parts of tourmaline solution, 35-40 parts of chromium slag crushed in step (1), 25-30 parts of activated carbon, put chromium slag and activated carbon into tourmaline solution and mix evenly, soak Fill the pores of chromium slag and activated carbon with tourmaline solution for 24 hours, pull out and drain to obtain chromium slag regenerated aggregate and activated carbon aggregate for subsequent use;

[0038] (3) Take 20~25 parts of cement and 5~10 parts of fly ash, put them into a mixing pot and mix evenly, and weigh 10~15% of the weight of cement and fly ash in water, add 3~5 parts of admixture, After stirring evenly, pour it into the mixing pot and mix for ...

Embodiment 1

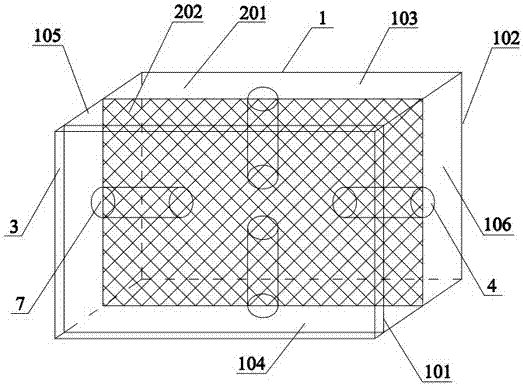

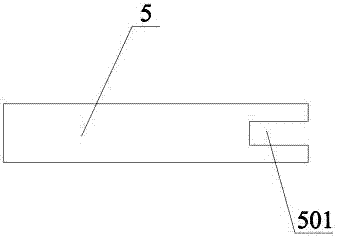

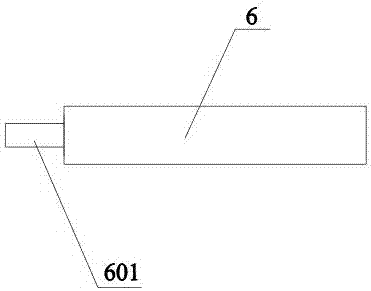

[0050] A spliced wall structure with fire prevention and purification functions, the spliced wall 1 includes a fireproof layer 2, a purification layer 3 and a connector 4, the fireproof layer 2 is a cubic structure, including opposite inner surfaces 101 and The outer side 102, the upper side 103 and the lower side 104, and the left side 105 and the right side 106, the fireproof layer 2 is composed of a concrete matrix 201 and a steel wire mesh 202 laid in the concrete matrix 201, the The purification layer 3 is coated on the inner side 101 of the fireproof layer 2, the connecting piece 4 includes the first connecting piece 5 and the second connecting piece 6, the upper side 103 and the lower side of the fireproofing layer 2 104. The centers of the left side 105 and the right side 106 are provided with connecting holes 7, and the connecting holes 7 of the upper side 103 and the left side 105 are installed with a first connecting hole 7 having the same length and depth as the...

Embodiment 2

[0060] A spliced wall structure with fire prevention and purification functions, the spliced wall 1 includes a fireproof layer 2, a purification layer 3 and a connector 4, the fireproof layer 2 is a cubic structure, including opposite inner surfaces 101 and The outer side 102, the upper side 103 and the lower side 104, and the left side 105 and the right side 106, the fireproof layer 2 is composed of a concrete matrix 201 and a steel wire mesh 202 laid in the concrete matrix 201, the The purification layer 3 is coated on the inner side 101 of the fireproof layer 2, the connecting piece 4 includes the first connecting piece 5 and the second connecting piece 6, the upper side 103 and the lower side of the fireproofing layer 2 104. The centers of the left side 105 and the right side 106 are provided with connecting holes 7, and the connecting holes 7 of the upper side 103 and the left side 105 are installed with a first connecting hole 7 having the same length and depth as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com