Split type cooling stove shell and cooling stove

A split type and shell technology, which is applied in the direction of fluid heaters, lighting and heating equipment, water heaters, etc., can solve the problems of unfavorable enterprises with diversified production structures, difficulties in ensuring the accuracy of production processes, and limitations in process processing, etc., to achieve Conducive to production innovation and progress, increase practicality, and reduce the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

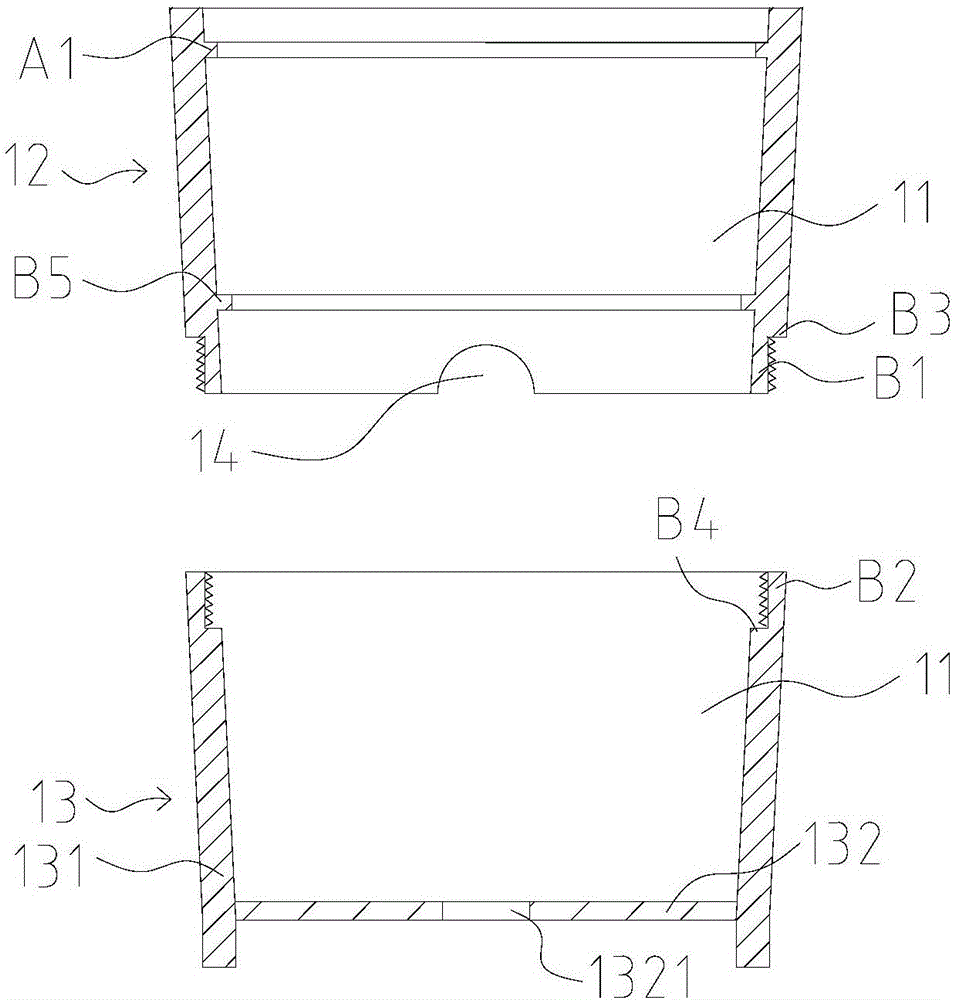

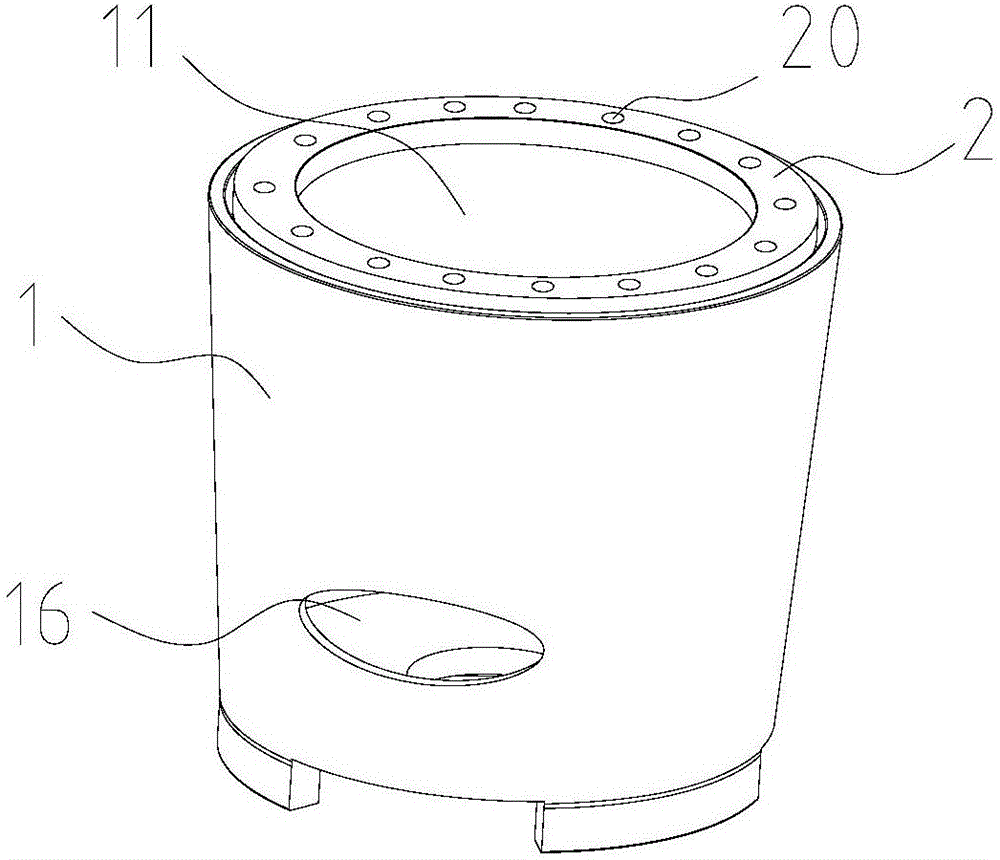

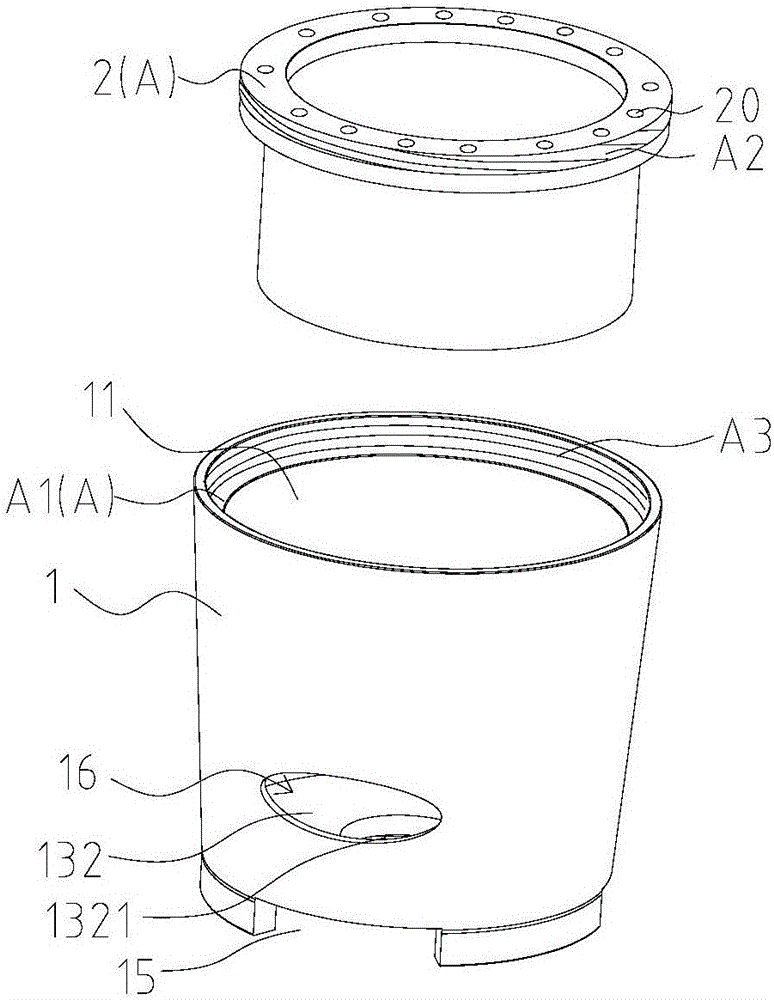

[0045] see Figures 1 to 4 , the split-type cooler shell of the present invention includes a shell main body 1, and the shell main body 1 is provided with a shell cavity 11 for accommodating the core of the cool stove. The upper casing 12 and the lower casing 13, the lower end of the upper casing 12 and the upper end of the lower casing 13 are connected by a threaded connection structure, the upper casing 12 and the lower casing 13 are connected by relative rotation, the upper casing 12 and the lower casing 13 Relative rotation in the opposite direction realizes disassembly.

[0046] Compared with existing products, the upper casing 12 and the lower casing 13 of the design of the present invention are connected by a threaded connection structure, so that the shell body 1 can be detached into the upper casing 12 and the lower casing 13 through the threaded connection structure, free from Limited by the overall height of the shell body 1, the upper shell 12 and the lower shell ...

Embodiment 2

[0079] This embodiment is another setting method relative to Embodiment 1, see Figure 12, the main difference between this embodiment and Embodiment 1 is that a circular upper connecting portion B6 is provided on the inner side of the lower end of the upper housing 12, and a circular lower connecting portion B7 is provided at the upper end of the lower housing 13. The upper connecting portion B6 is provided with an internal thread, the lower connecting portion B7 is provided with an external thread, and the upper connecting portion B6 is threaded with the lower connecting portion B7; the threaded connection is simple and reliable in structure.

[0080] see Figure 12 , the inner side of the lower end of the upper housing 12 is provided with a round of upper steps B8, and the outer side of the upper end of the lower housing 13 is provided with a round of lower steps B9, the upper steps B8 and the lower steps B9 are adapted, the side walls of the upper steps B8 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com