Air draft dedusting device of feeding position of ring cooling machine

A technology of dust removal device and ring cooler, which is applied in the direction of furnace control device, treatment of discharged materials, furnace, etc., to achieve the effect of ensuring dust removal effect, long life and improving working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

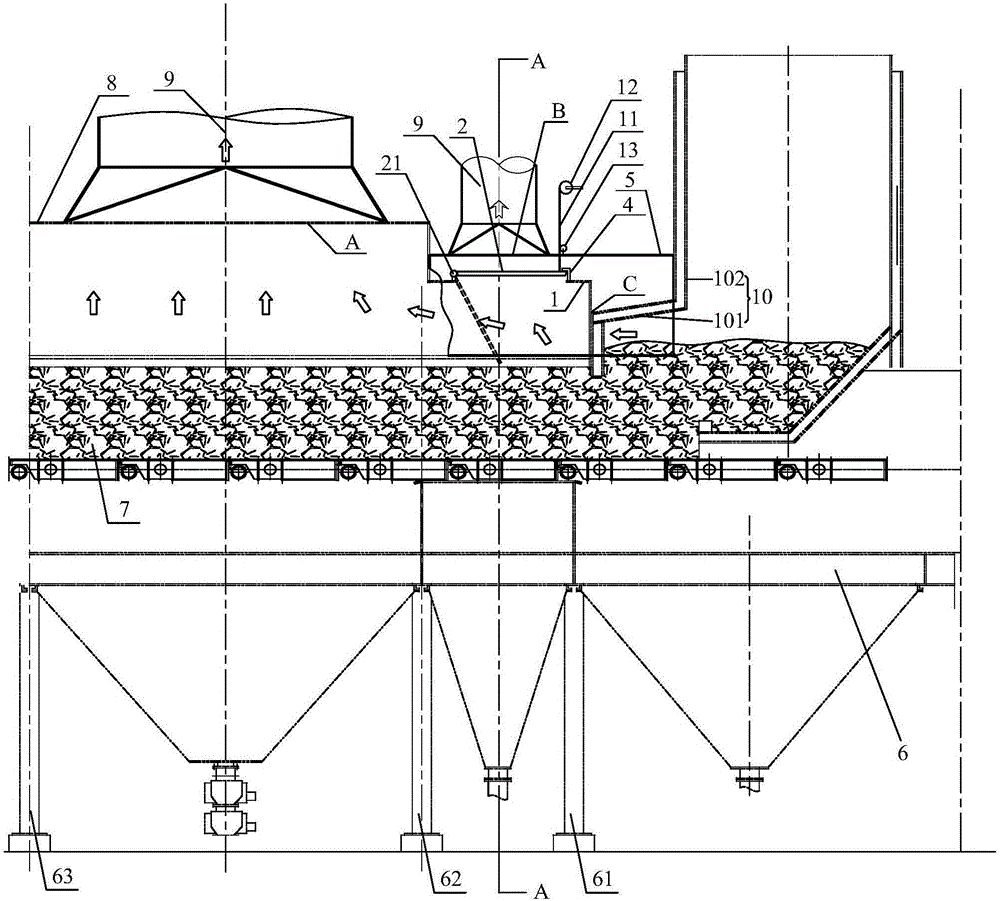

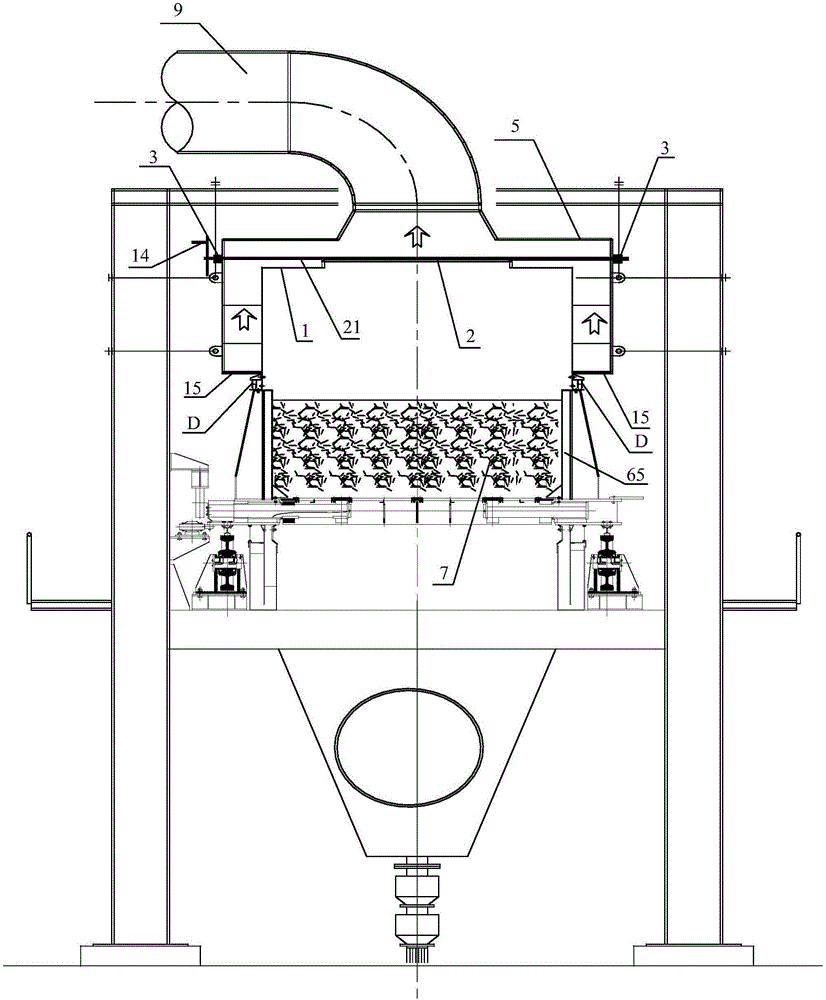

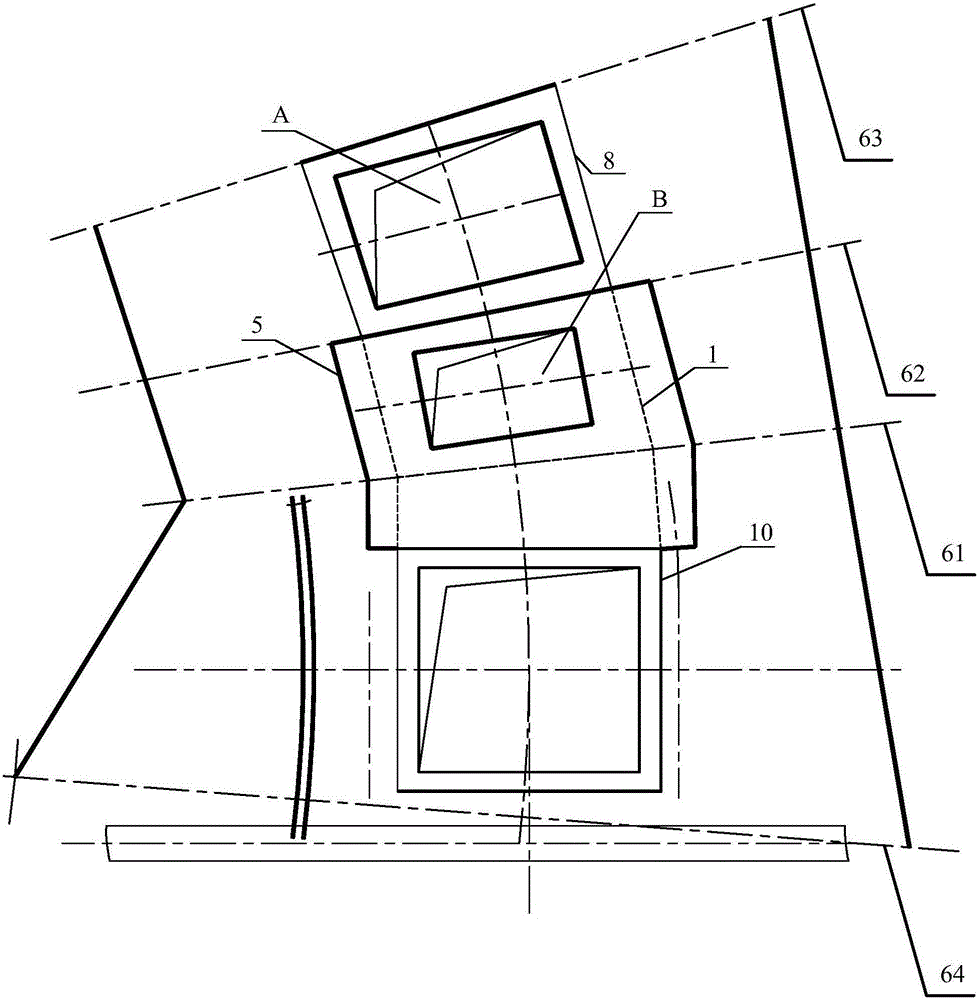

[0029] In order to solve the problem that the partitions in the prior art cannot effectively solve the problem that the dust removal air intake has an adverse effect on the high temperature air intake, and the dust will pass through the gap between the trolley and the fume hood, the horizontal section between the fume hood and the material guide chute Problems with gap overflow between, such as figure 1 shown, and see figure 2 and image 3 The embodiment of the present invention provides a suction and dust removal device for the material receiving point of the annular cooler. The suction and dust removal device for the material receiving point of the annular cooler includes: a first fume hood 1, an adjusting baffle door 2, a door shaft bearing 3, Limiting angle steel 4 and adiabatic dust cover 5;

[0030] The first fume hood 1 is covered above the sintered mineral material 7 between the second axis 61 and the third axis 62 of the annular cooler 6, and the first fume hood 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com