Electric vehicle vibration integrated test platform

A comprehensive test and electric vehicle technology, which is applied in vibration testing, vehicle testing, machine/structural component testing, etc., can solve problems such as user inconvenience, inability to accurately control the operation status of electric vehicles, safety accidents, etc., and achieve operational simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

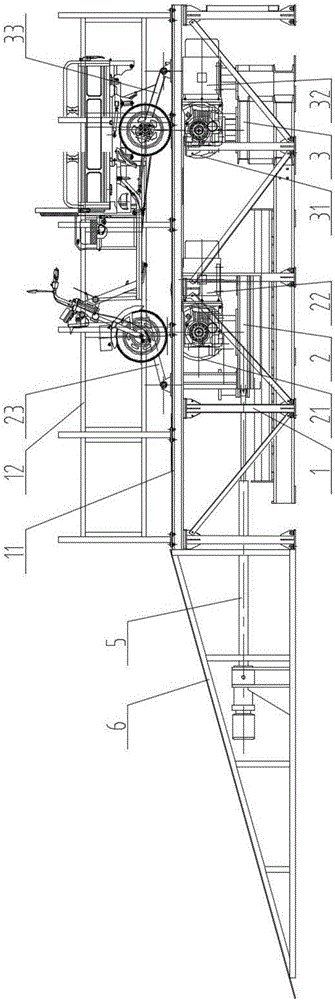

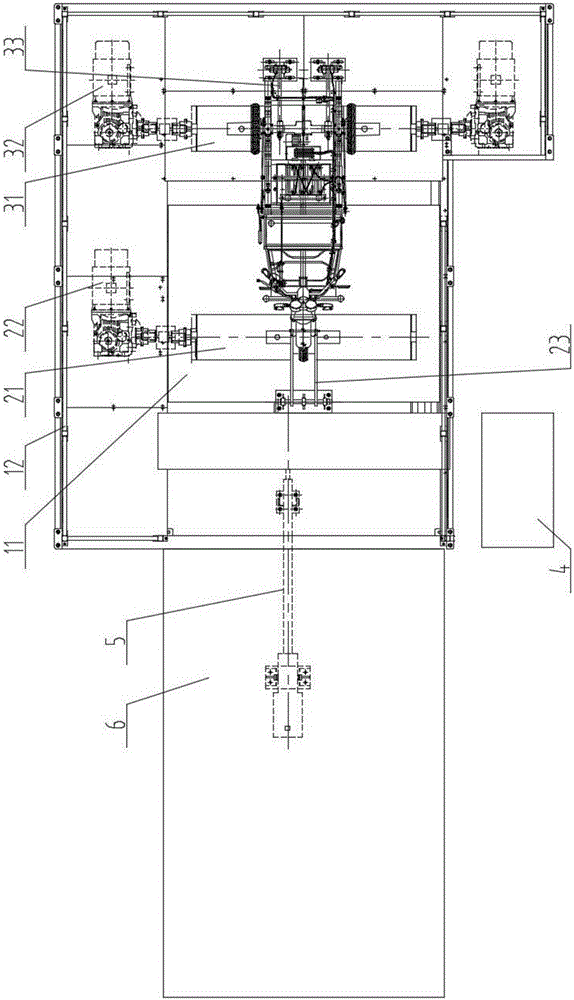

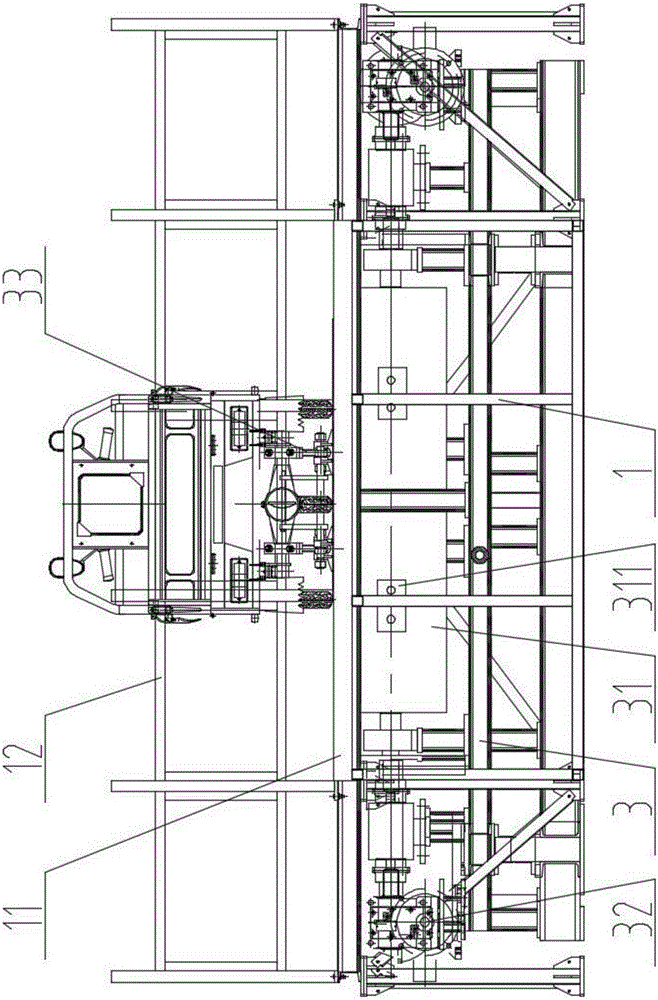

[0024] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 shown on the left is the front description).

[0025] Such as Figure 1 to Figure 3 As shown, the electric vehicle vehicle vibration comprehensive test platform includes a support frame 1, a front wheel support frame 2, a rear wheel support frame 3 and an electric control device 4.

[0026] The upper plane of the support frame 1 is covered with a platform panel 11 .

[0027] The front wheel support frame 2 is installed on the front part of the support frame 1, and includes a front roller 21, a front roller drive 22 and a front axle positioning mechanism 23; , and the distance between the axis center of the front roller 21 and the upper surface of the platform panel 11 is smaller than the radius of the front roller 21, that is, the roller surface of the front roller 21 protrudes from the upper surface of the platform panel 11, and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com