Crude oil automatic sampling and moisture content determining instrument

An automatic sampling and water content technology, applied in sampling devices, instruments, measuring devices, etc., can solve the problems of inaccurate monitoring results, many distillation and testing procedures, and large human influence factors, so as to avoid the influence of human factors and achieve high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

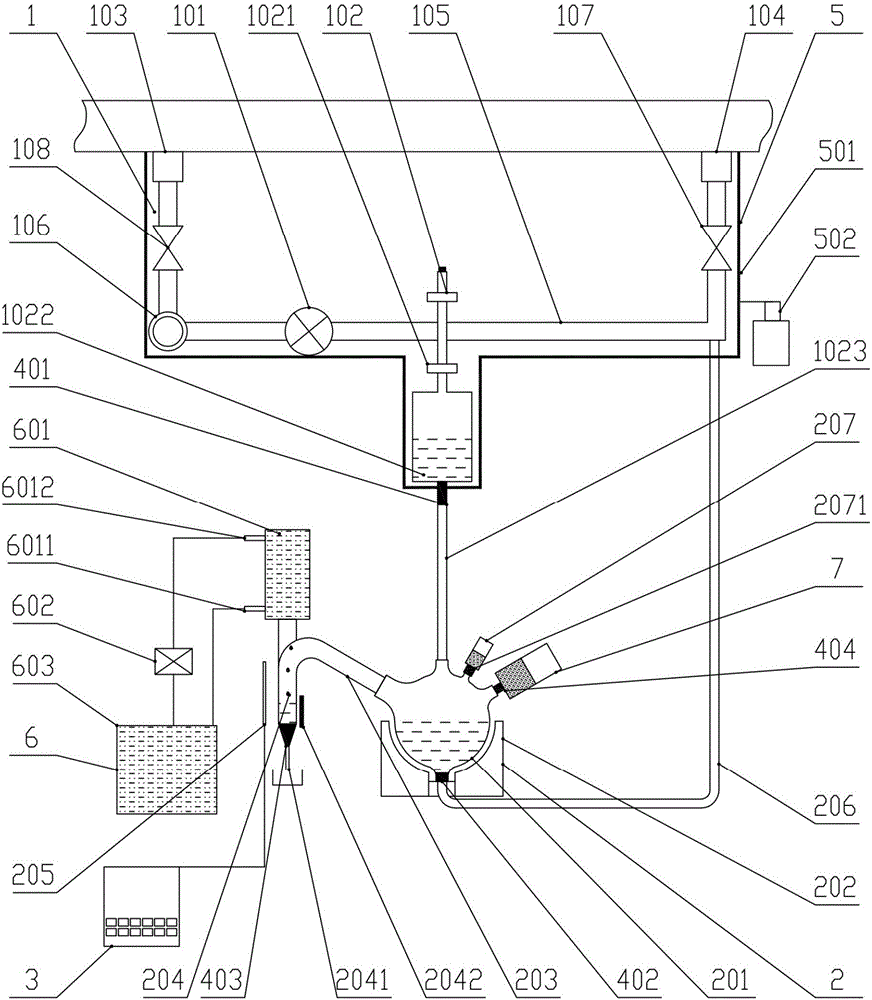

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] figure 1 It schematically shows a crude oil automatic sampling and water content measuring instrument device according to an embodiment of the present invention. This measuring instrument comprises automatic sampling unit 1, and automatic sampling unit 1 comprises circulation pump 101, sampler 102 and bypass oil pipe 105, and bypass oil pipe 105 is communicated with main oil pipe by oil inlet 103, oil return port 104, and oil inlet 103 , circulating pump 101, filter 106, sampler 102 and oil return port 104 are communicated in sequence through bypass oil pipe 105,

[0026] The sampler 102 is provided with a sampling pump 1021, and the sampling pump 1021 is communicated with the bypass oil pipe 105, and the sampling pump 1021 can extract the crude oil in the bypass oil pipe 105, and the sampling pump 1021 is also communicated with the sampling container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com