Phase delay film and three-dimensional display device

A technology of a stereoscopic display device and a phase retardation film, which is applied in the direction of instruments, polarizing elements, optics, etc., can solve problems affecting the stereoscopic display effect, uneven light and dark stripes, large signal delay, etc., and achieve the effect of improving the stereoscopic display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

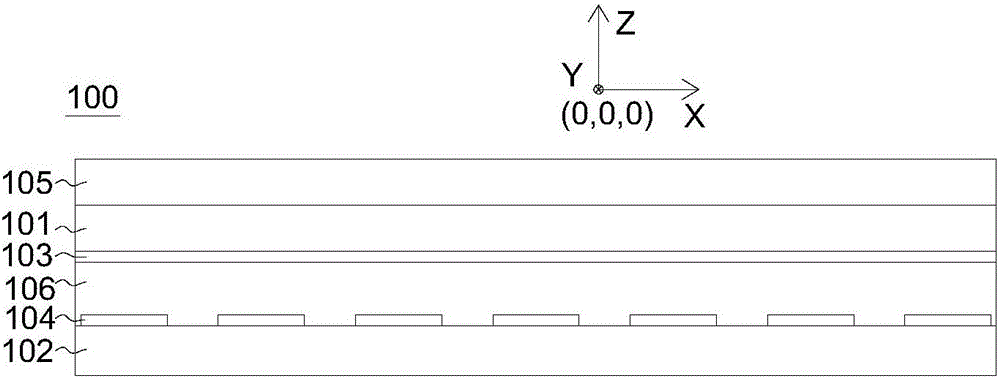

[0038] figure 1 A schematic structural diagram of an existing liquid crystal slit grating 100 is shown. see figure 1 , the liquid crystal slit grating 100 mainly includes an upper substrate 101 and a lower substrate 102 facing to each other, a liquid crystal layer 106 arranged between the upper substrate 101 and the lower substrate 102, and a liquid crystal layer 106 arranged on the surface of the upper substrate 101 away from the lower substrate 102. The upper polarizer 105. A first electrode 103 is provided on the surface of the upper substrate 101 close to the lower substrate 102 , and the first electrode 103 is a full-surface electrode. A second electrode 104 is provided on the side of the lower substrate 102 close to the upper substrate 101, and the second electrodes 104 are several figure 1 The shown strip electrodes have the same width in the X direction and are separated by a certain gap. These strip electrodes are arranged in parallel in the X direction and extend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com