Full-automatic polarizer attaching machine

A partial sticking machine and fully automatic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of low processing flow efficiency, low product quality, slow speed, etc., reduce the workload and labor costs of personnel, and improve processing Quality, fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

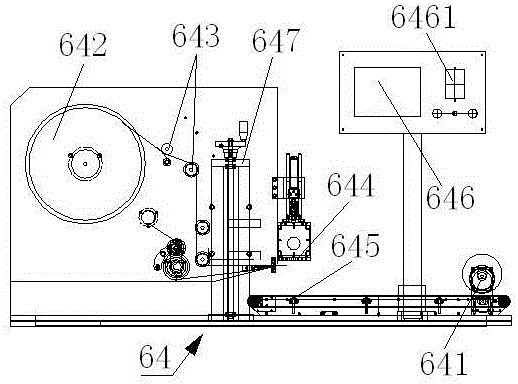

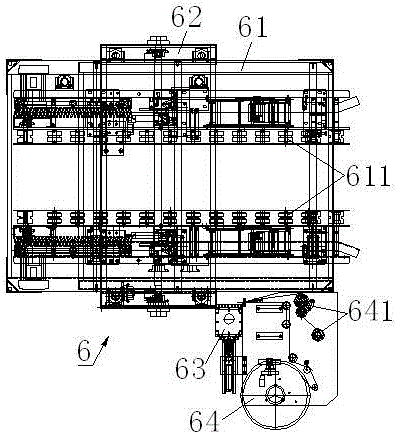

[0016] refer to Figure 1 to Figure 2 , a full-automatic biasing machine for attaching polarizers to LCD substrates, including a body 64, the body 64 is located in the biasing production line 6, and the biasing production line 6 includes a support wall 61, a conveying device 62, a driving mechanism 63, and a body 64, the conveying device 62 is installed on both sides of the supporting wall 61 and can slide relative to the supporting wall 61, the driving mechanism 63 is fixedly installed on one side edge of the supporting wall 61, and the body 64 is connected to the driving mechanism 63, in this embodiment , the drive mechanism 63 is an air cylinder.

[0017] There are two rows of rolling pulleys 611 inside the supporting wall 61 , a patch conveying assembly 641 is installed on the body 64 , and the driving mechanism 63 drives the patch conveying assembly 641 to move. Specifically, the LCD substrate to be mounted is moved into the conveying area of the conveying device 62 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com