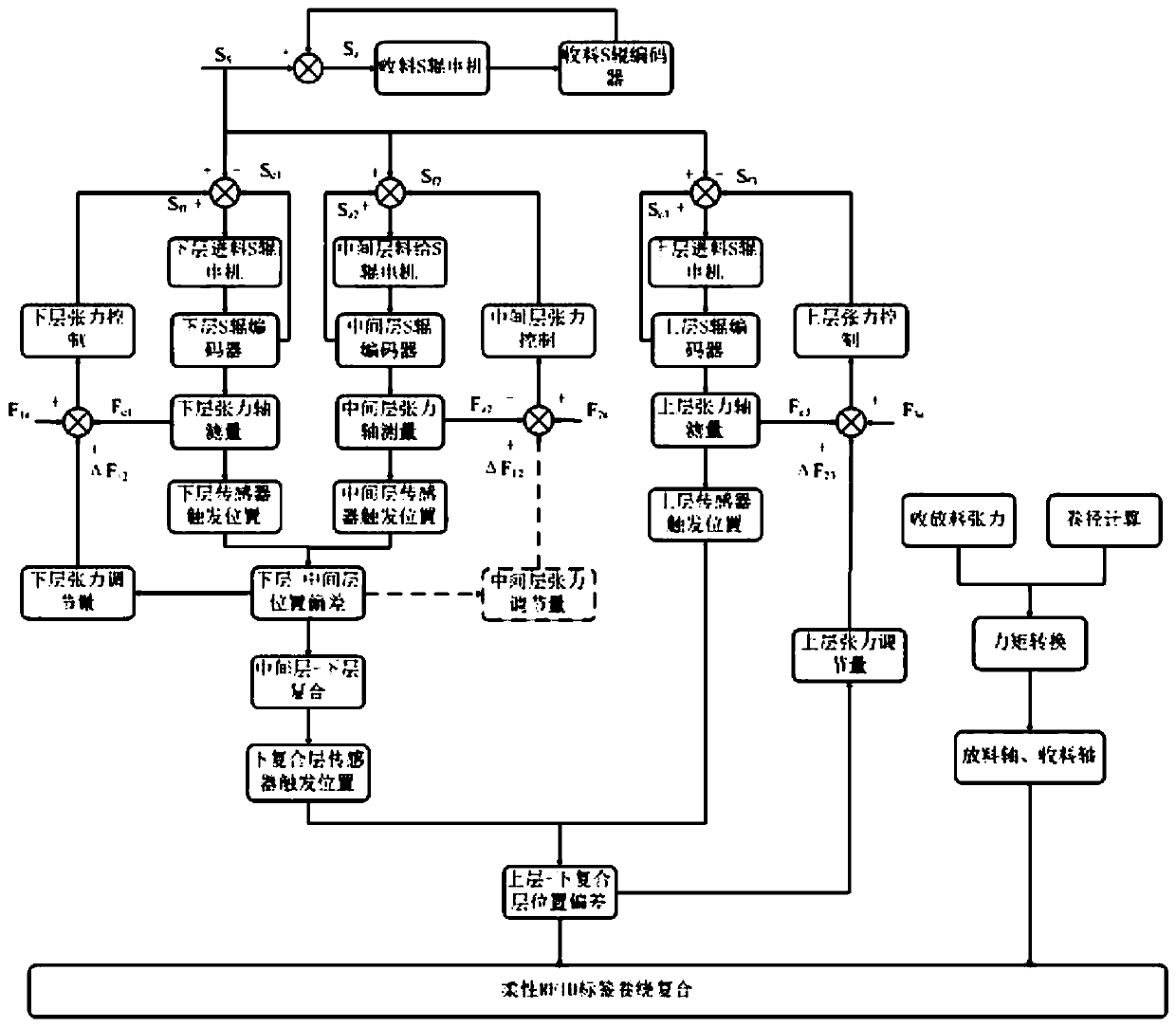

Multi-layer registration control system and method for flexible label winding lamination

A control system and label roll technology, applied in the field of RFID electronic label compounding, can solve problems such as inability to use multi-layer films for high-speed compounding, inability to effectively predict tension changes, and unsatisfactory response speed, and achieve accurate and direct data and stable operation. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

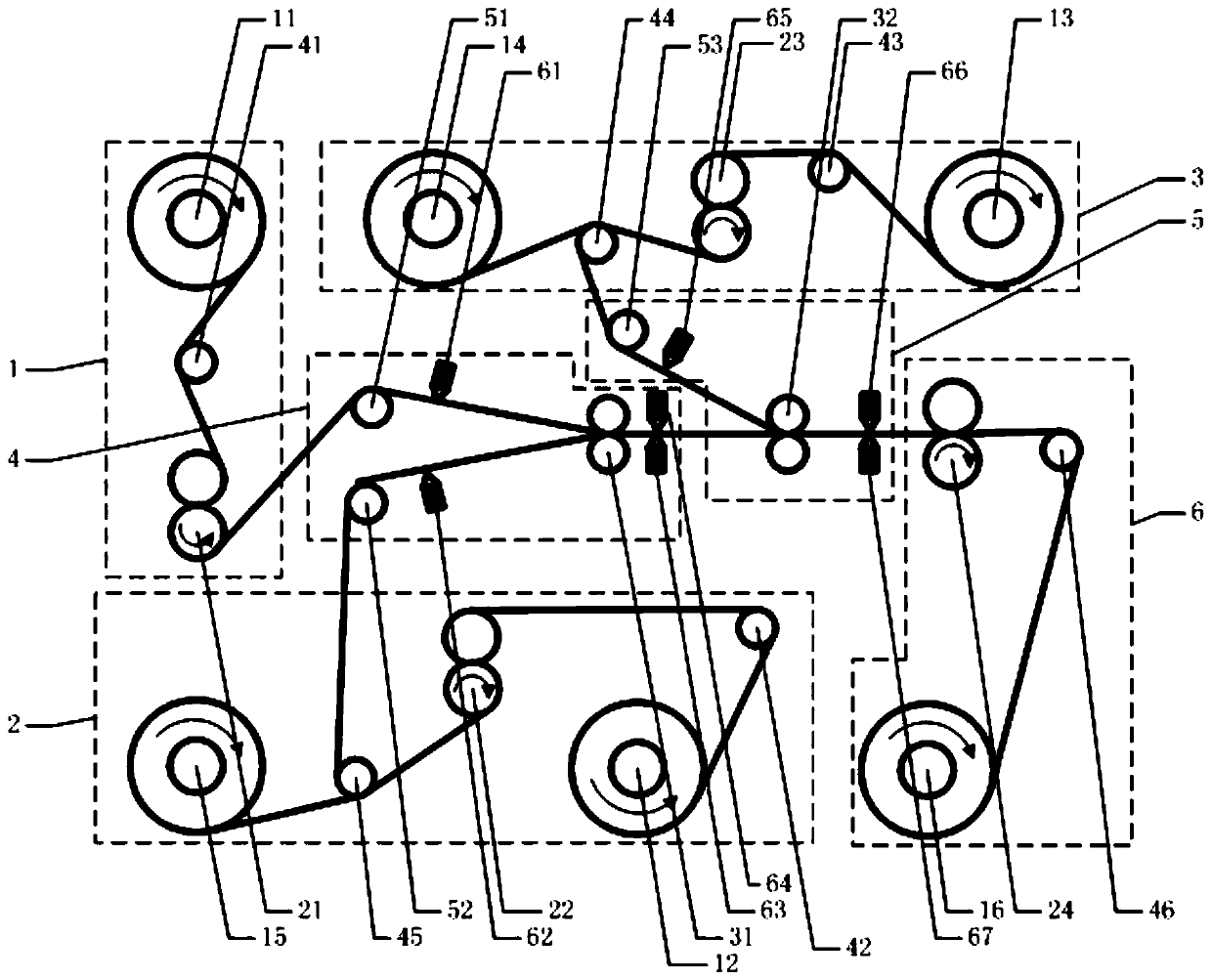

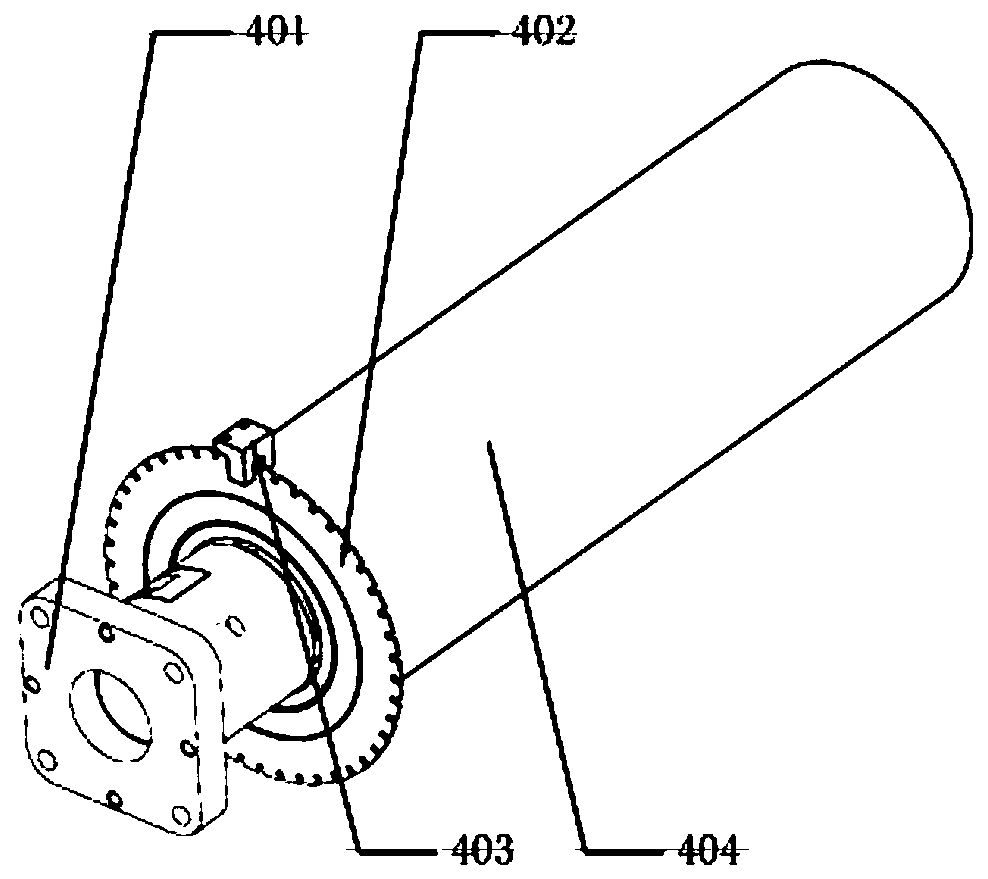

[0031] figure 1 It is a schematic diagram of the system structure according to the preferred embodiment of the present invention. It is divided into six units. Among them, the middle layer unwinding unit (1) consists of an Inlay unwinding shaft (11), an Inlay unwinding linear speed detection idler roller and (41). )Inlay feeding S roller (21); lower film unwinding unit (2), composed of lower film unwin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com