Upper electrode component and semiconductor processing equipment

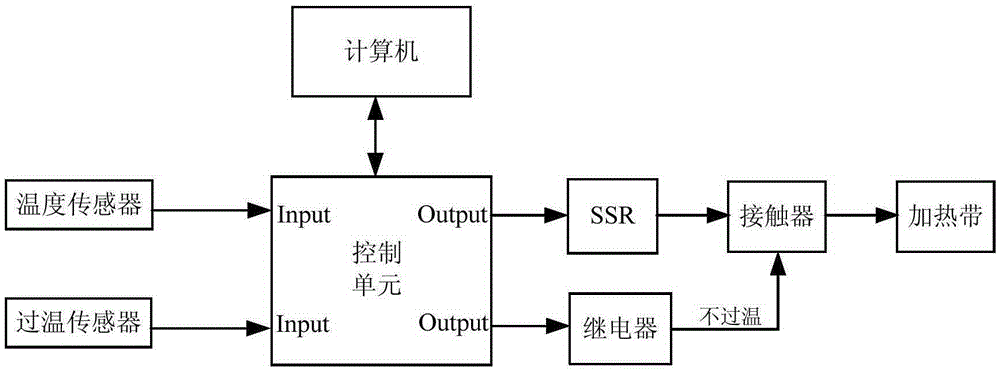

A technology of electrode components and heating belts, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of uneven temperature distribution, inaccurate temperature control methods, and low heat transfer efficiency of the ceramic barrel 2, and achieve improved The effect of temperature control accuracy and temperature uniformity, improving heat transfer efficiency, and improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order for those skilled in the art to better understand the technical solutions of the present invention, the upper electrode assembly and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

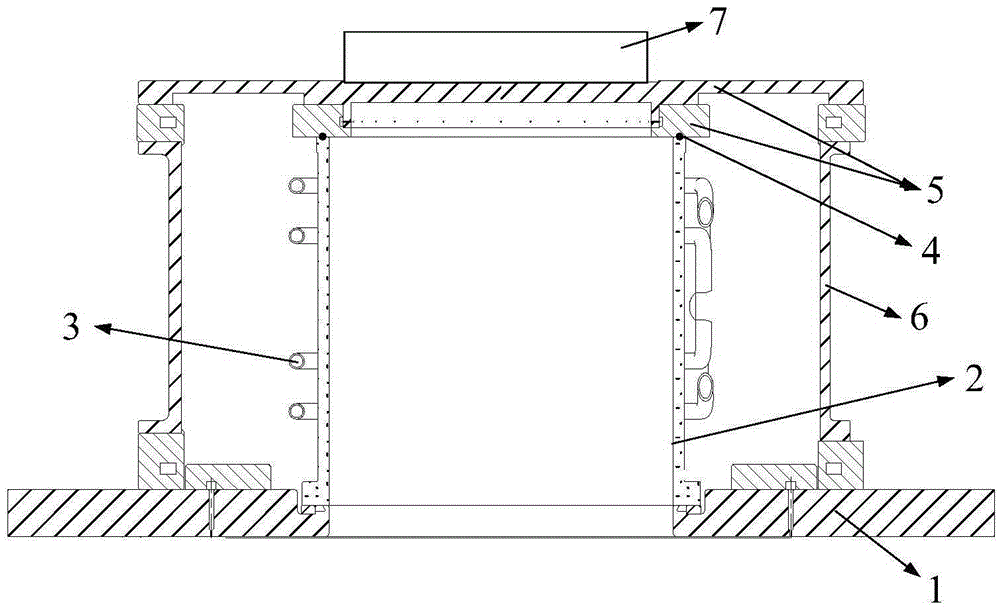

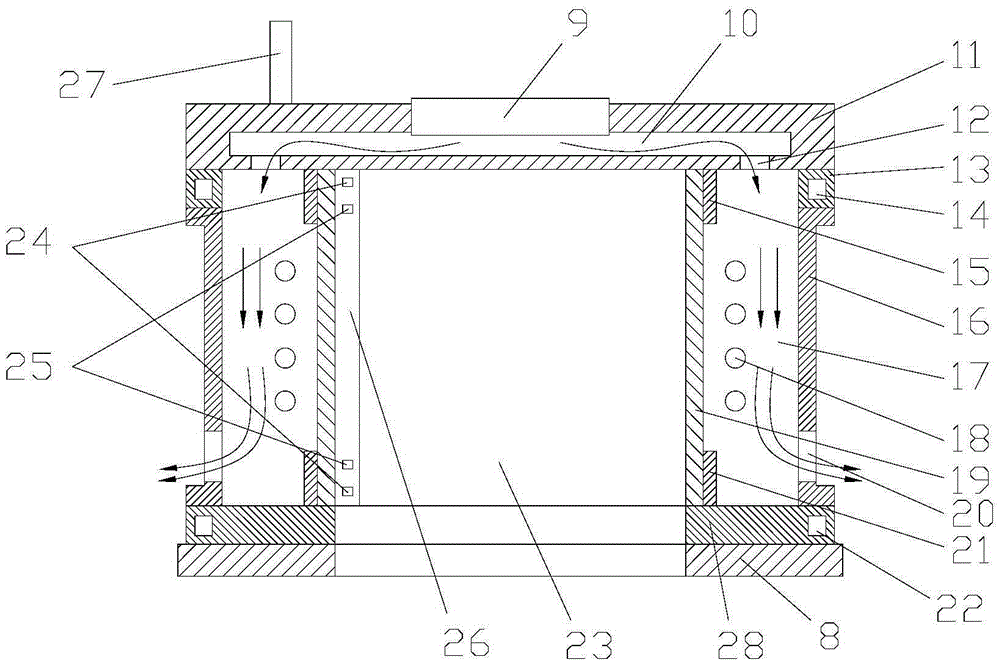

[0028] figure 2 A cross-sectional view of an upper electrode assembly provided by an embodiment of the present invention. see figure 2 , the upper electrode assembly includes a medium barrel 19, a coil 18, a heating mechanism and a cooling mechanism. Wherein, the medium barrel 19 is arranged on the chamber cover plate 8, which is made of insulating material such as ceramics, and is used to isolate the plasma generation environment from the atmospheric environment; the coil 18 is a three-dimensional coil, and surrounds the medium barrel 19 The surrounding area is used to convert the process gas in the dielectric barrel 19 into high-energy plasma under the action of high radio fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com