Electrode coating method

An electrode sheet and coating technology, which is applied in the direction of electrode collector coating, electrode manufacturing, battery electrodes, etc., can solve the problem that the amount of electrode sheet coating is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

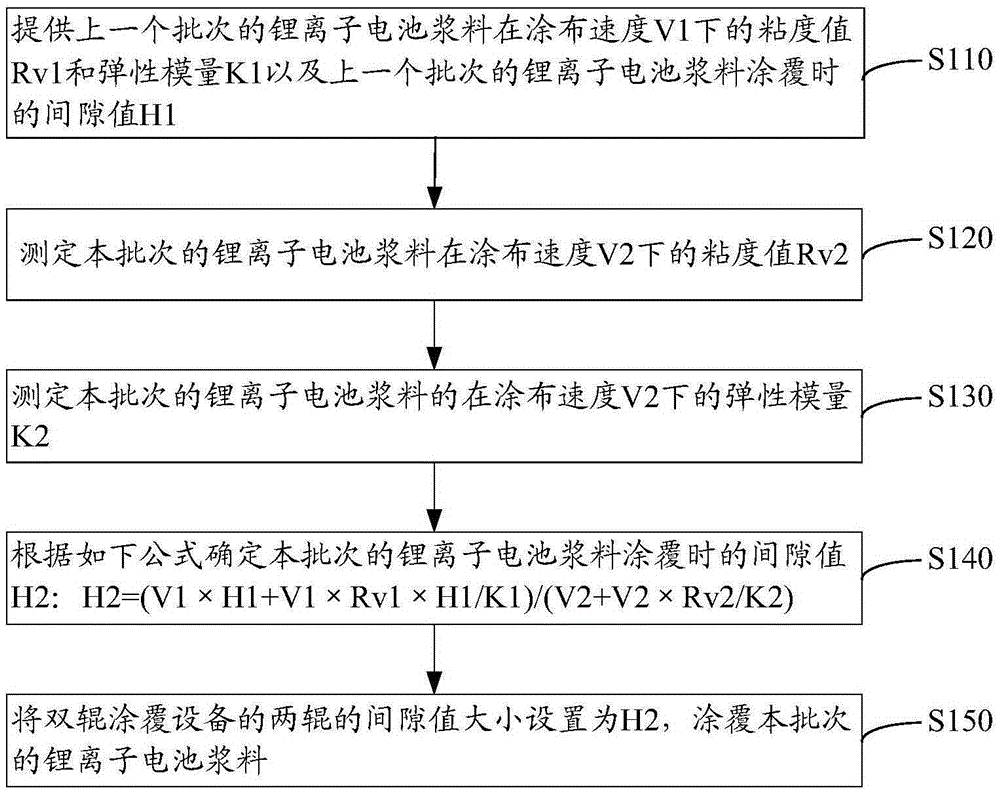

[0018] see figure 1 , an electrode sheet coating method according to an embodiment includes the following steps S110 to S150.

[0019] Step S110: Provide the viscosity value Rv1 and elastic modulus K1 of the previous batch of lithium-ion battery slurry at the coating speed V1 and the gap value H1 of the previous batch of lithium-ion battery slurry during coating.

[0020] The coating speed V1 is a set value, which is set according to the process conditions.

[0021] The viscosity value Rv1 and elastic modulus K1 at the coating speed V1 are measured values. The viscosity value Rv1 is measured by a rheometer, and the elastic modulus K1 is measured by an optical lever method measuring device.

[0022] The gap value H1 during coating is a set value, which can be directly read by the double-roller coating equipment.

[0023] Step S120: Measure the viscosity value Rv2 of this batch of lithium-ion battery slurry at the coating speed V2.

[0024] The coating speed V2 is a set valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com