Liquid crystal coating device and liquid crystal coating method

A technology of coating device and coating method, which is applied to the device, coating, optics and other directions of coating liquid on the surface, which can solve the problems of long injection time, bubble coating, expensive equipment and process, etc., and achieve the improvement of bubble or liquid crystal Effects of non-uniform film, labor and time saving, and simplification of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

[0035] In the figures, structurally similar units are denoted by the same reference numerals.

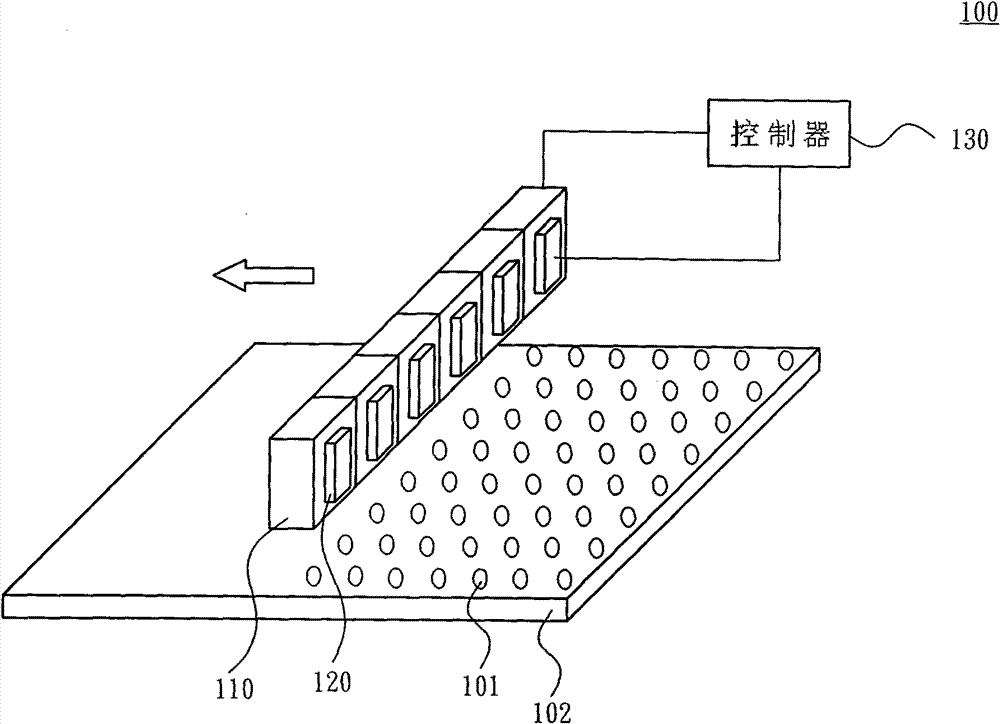

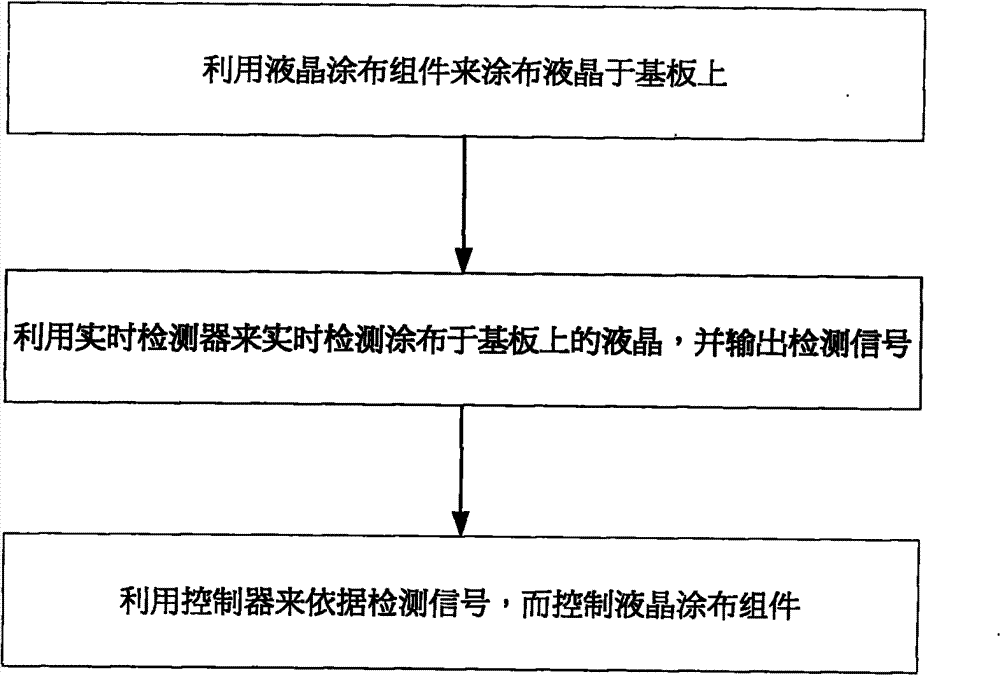

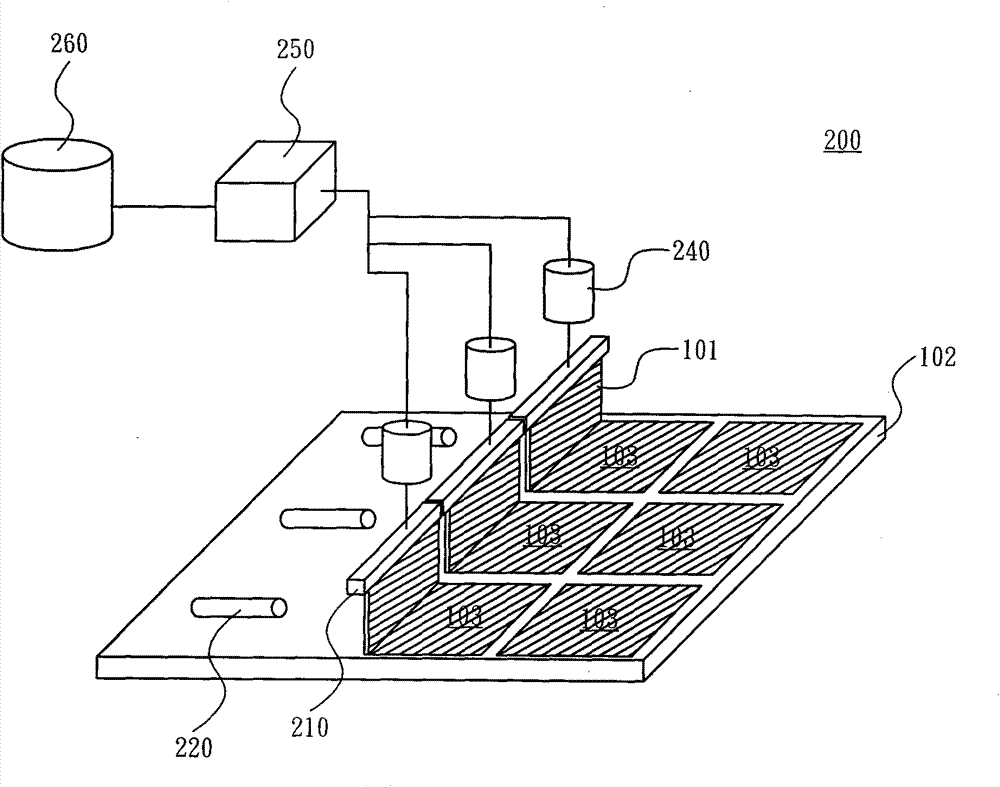

[0036] Please refer to figure 1 , which shows a schematic diagram of a liquid crystal coating device according to a first embodiment of the present invention. The liquid crystal coating device 100 of this embodiment is used to coat and form a liquid crystal 101 between two transparent substrates 102 to form a liquid crystal display panel. The liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com