Connection head of assembling POGO PIN with high efficiency and production method thereof

A production method and connector technology are applied in the field of high-efficiency assembly of POGOPIN connectors, which can solve the problems of unfavorable multi-PIN short-circuit connection, high production defect rate and cost, and small welding space, and achieve good sealing, simple process, and welding. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

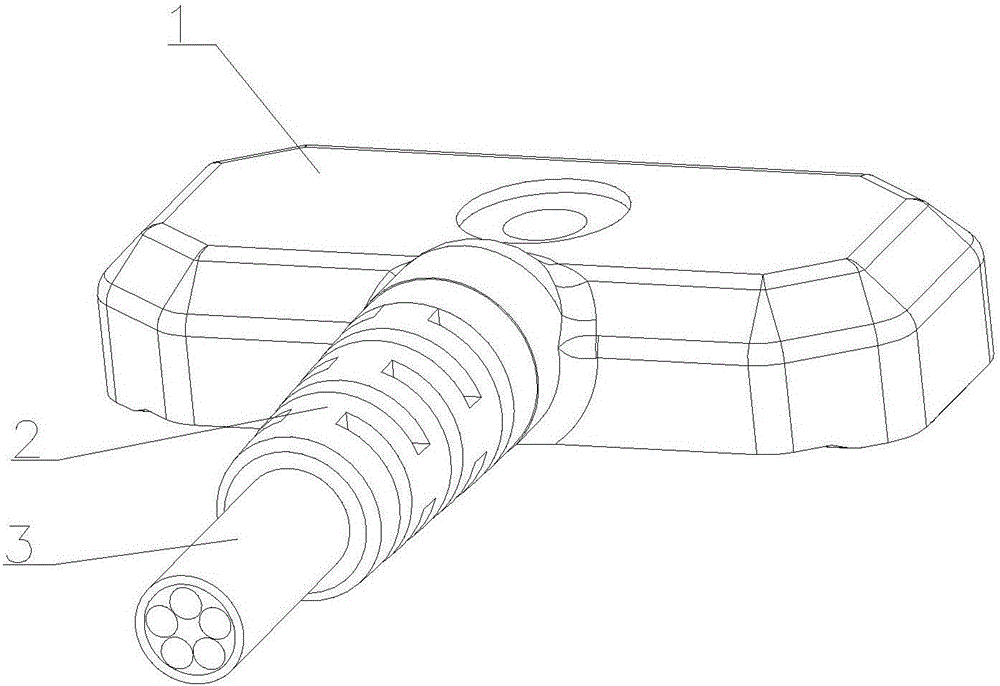

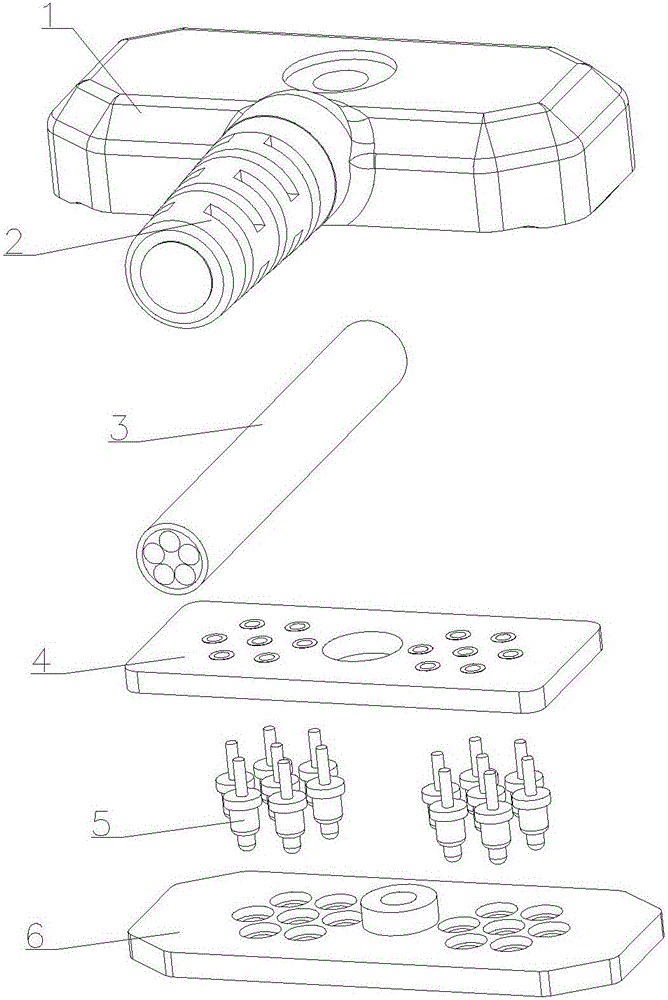

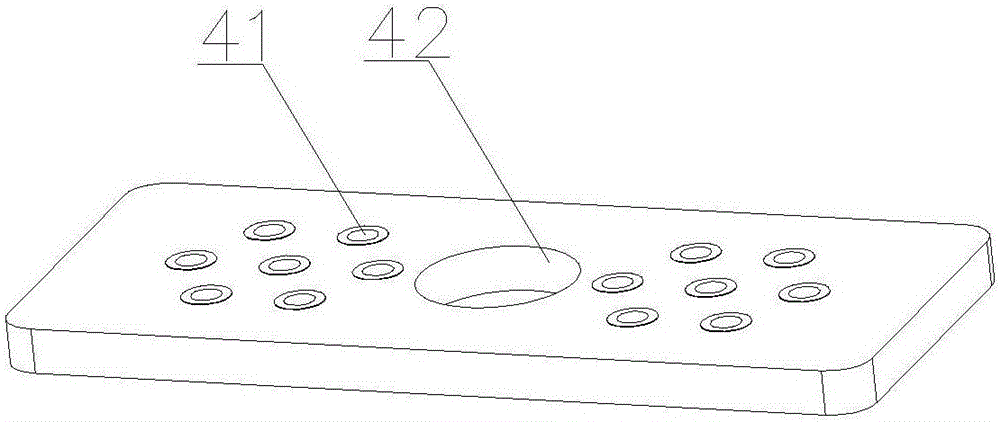

[0039] refer to Figure 1-Figure 5 , an efficient assembly POGO PIN connector of the present invention, comprising an outer shell 1, a foldable protective cover 2, a wire 3, a positioning plate 4, a pogo pin 5 and a circuit board 6, one end of the pogo pin 5 passes through the positioning plate 4, and the other end Through the circuit board 6, the pogo pin5 is electrically connected to the circuit board 6, and the wire 3 is electrically connected to the circuit board 6 through the outer shell 1 and the foldable protective cover 2, and the foldable protective cover 2 sets On the wire 3 and fixedly connected with the outer casing 1. The positioning plate 4 is provided with a pogo pin mounting hole and a positioning hole 42, the pogo pin5 mounting hole is used to insert the pogo pin5 and limit the position, and the positioning hole 42 is used to cooperate with the positioning protrusion 62 on the circuit board 6 for positioning The relative positions of the circuit board 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com