Cylindrical battery comprising pressurizing part and method of manufacturing same

A cylindrical battery, cylindrical container technology, applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, battery, etc., can solve problems such as battery life characteristics reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] 90% by weight LiNi as positive electrode active material 0.5 mn 1.5 o 4 , 5% by weight of a conductive agent (Super-P) and 5% by weight of a binder (PVdF) were mixed with N-methyl-2-pyrrolidone (NMP) to prepare a positive electrode mixture. Subsequently, on an aluminum foil having a thickness of 20 μm, the positive electrode mixture was coated, pressed, and dried to manufacture a positive electrode.

[0104] 90% by weight of the negative electrode active material (Li 1.33 Ti 1.67 o 4 ), 5% by weight of a conductive agent (Super-P) and 5% by weight of a binder (PVdF) were mixed with NMP to prepare an anode mixture. Subsequently, on a copper foil having a thickness of 20 μm, the anode mixture was coated, pressed, and dried to manufacture an anode.

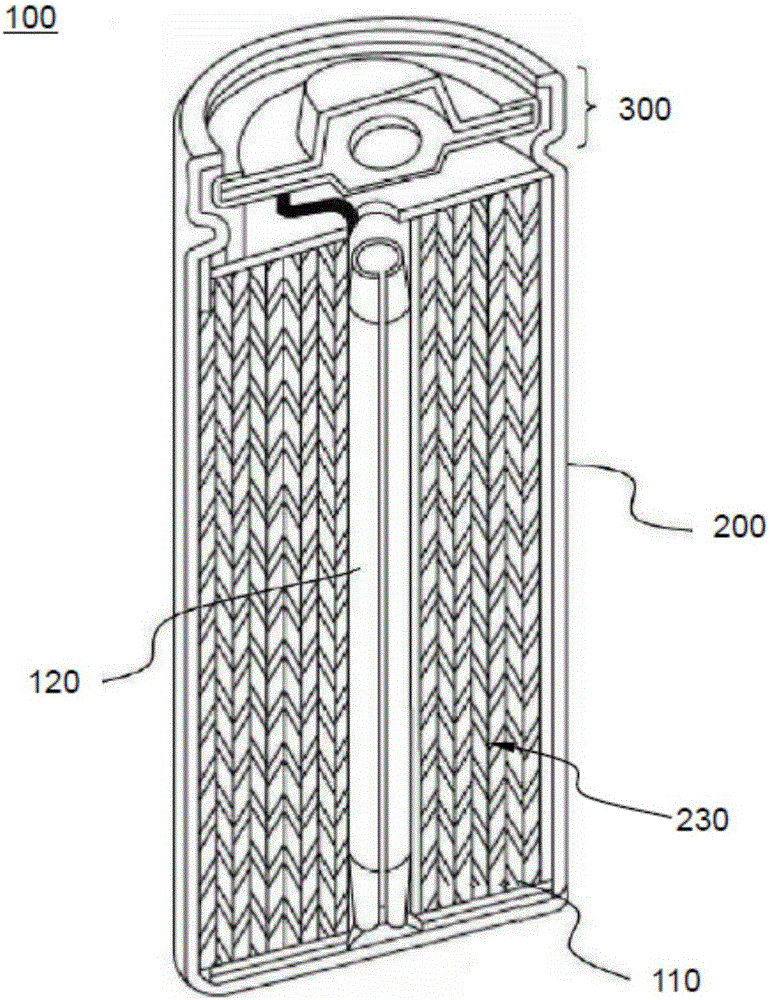

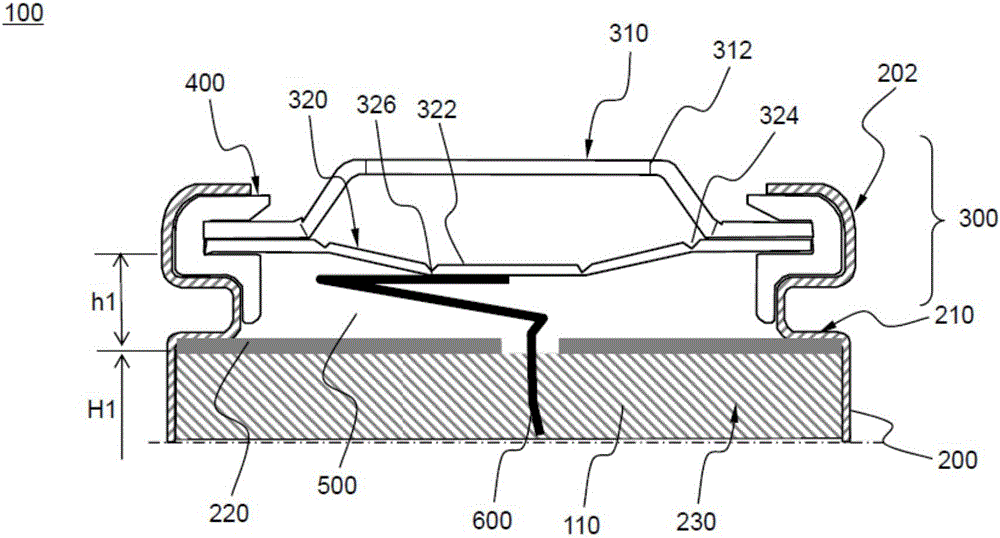

[0105] A separator having a thickness of 20 μm was inserted between the cathode and anode manufactured as described above to manufacture an electrode assembly. Subsequently, the electrode assembly was housed in a cylind...

Embodiment 2

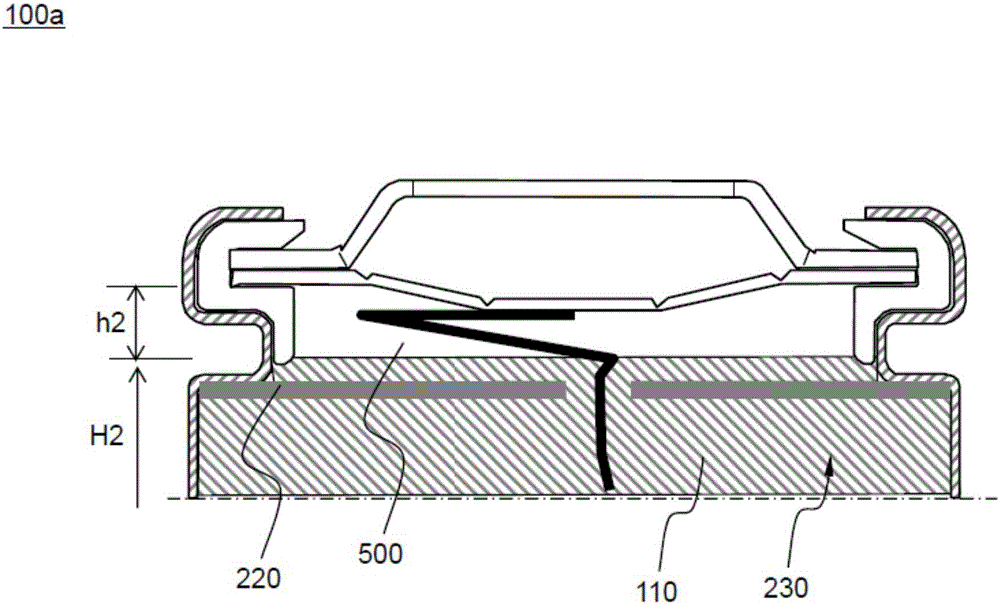

[0107] A cylindrical battery was fabricated in the same manner as in Example 1 except that 3.5 g of the electrolytic solution was injected into the cylindrical container. At this time, the volume of the pressurizing portion was 2.5% of the volume of the housing portion.

experiment Embodiment 1

[0111] The batteries manufactured according to Example 1, Example 2, and Comparative Example 1 were charged and discharged at 1C in a chamber at a temperature of 25°C to measure the capacity retention ratio of the batteries. The result is shown in Figure 8 and Figure 9 .

[0112] refer to Figure 8 , the capacity of the pouch-shaped battery fabricated according to Comparative Example 1 suddenly decreased as the pouch-shaped battery was repeatedly charged and discharged, while the cylindrical battery fabricated according to Example 1 exhibited high capacity retention even after 100 cycles Rate.

[0113] These results show that the use of a positive electrode active material containing a high content of Mn in a cylindrical battery including a pressurizing part is more effective than the case of using a positive electrode active material containing a high content of Mn in a pouch-shaped battery not including a pressurizing part. In this case, the life characteristics of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com