Long zhuang bun production method

A production method and technology of steamed buns, which are applied in the field of making Changzhuang steamed buns, can solve the problems of time-consuming, inconvenient selling, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

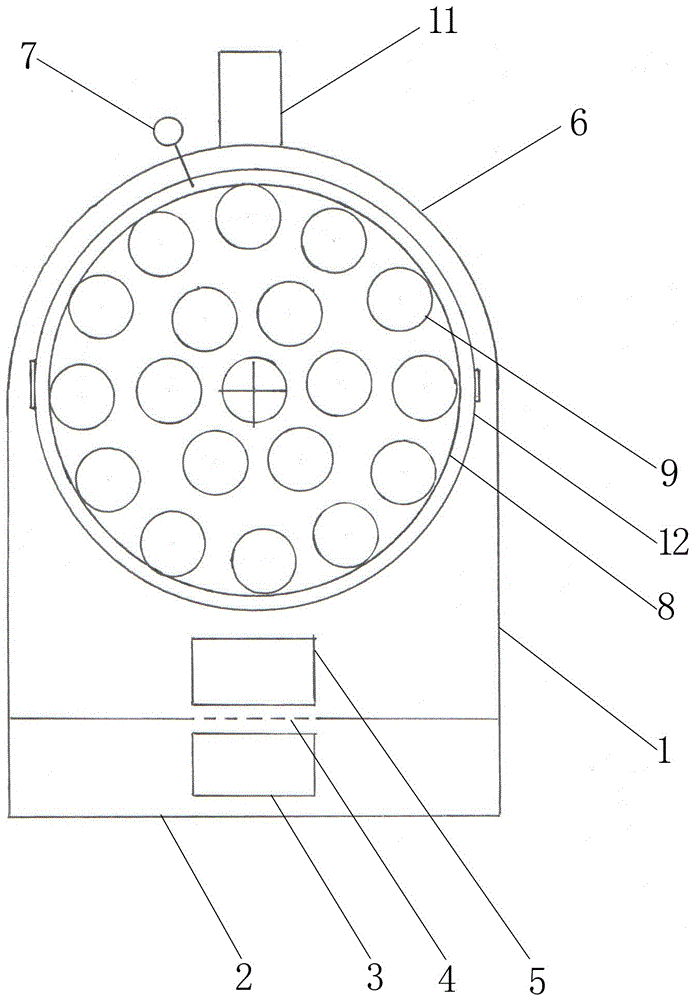

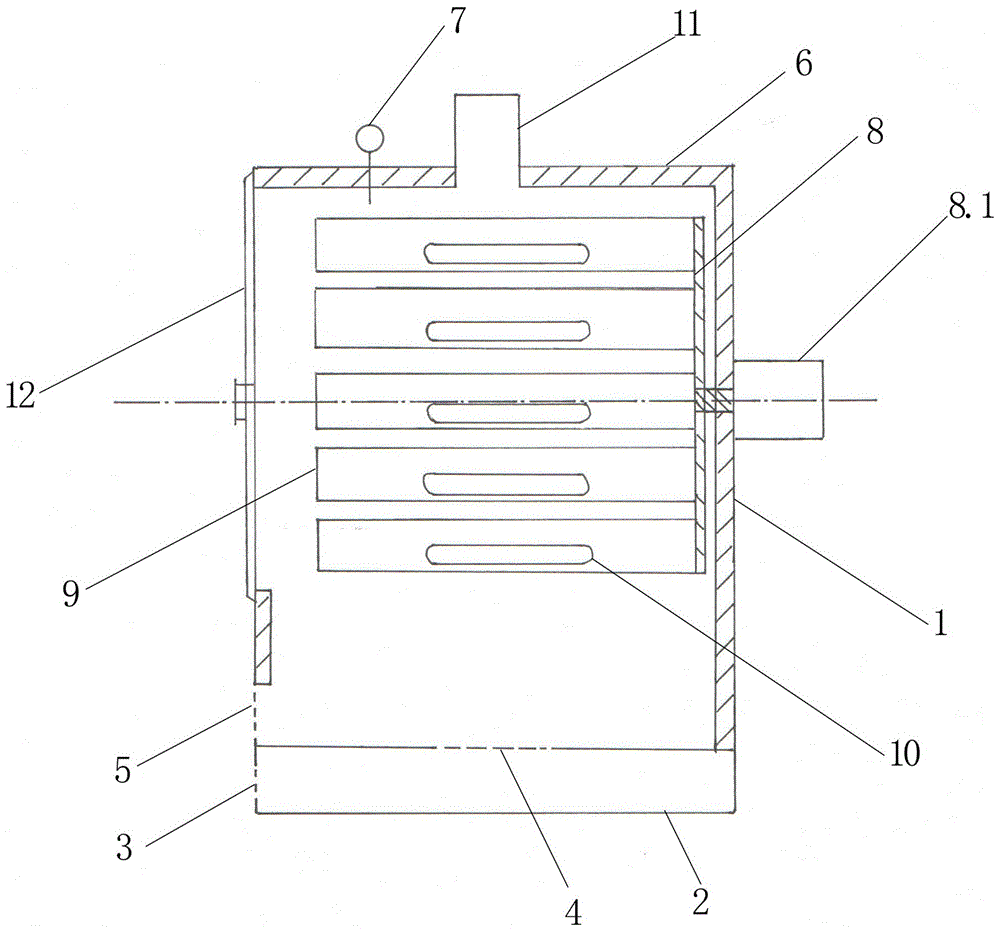

[0010] The specific production process of the Changzhuang steamed bun of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The method of making Changzhuang steamed buns is characterized in that it consists of four steps: kneading noodles, making steamed buns, rotating and baking in a tube, and taking out of the oven: ①Kneading noodles, adding 1 part of high-gluten wheat flour, adding 0.3-0.4 parts of warm water and Make dough into dough for later use; ②Make steamed buns (10), take the dough in step ① to make 50-100 grams of dough, knead it on the chopping board to form a strip-shaped steamed bun with a diameter of 15-25mm and a length of 120-200mm Blank (10); ③Rotate and bake in the tube, scoop up the strip-shaped steamed bun (10) with a semicircular steamed bun shovel, put it into the rotating stainless steel tube, and bake it in a baking oven at 220-240°C; ④ out of the oven, through the glass door (12), when the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com