Coconut shucking machine

A coconut shelling machine and coconut technology, which are applied in the fields of shelling, pod removal, food science, etc., can solve the problems of poor shelling effect and other problems, and achieve the effect of high shelling efficiency and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

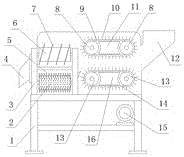

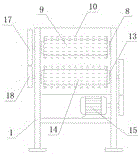

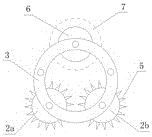

[0016] Such as figure 1 , figure 2 and image 3 Shown, a kind of coconut peeling machine comprises frame 1, feed hopper 12 and discharge opening 4, and described frame 1 is provided with power machine 15, mounting base 3, upper grinding disc 11 and lower grinding disc 16, and described power machine 15 refers to machines that generate power, including electric motors, internal combustion engines or other devices that can provide rotational power. One pair of rollers 2a, two pairs of rollers 2b and shifting rollers 6 are installed on the mounting base 3, nail claws 5 are set on the one pair of rollers 2a and the second pair of rollers 2b, the one pair of rollers 2a and the pair of rollers 2b Roller two 2b relatively rotates under the drive of described power machine 15, and described shifting roller 6 is arranged on described pair of rollers 2a and described pair of rollers 2b above, and described shifting roller 6 is provided with screw dial 7; Roller one 2a and described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com