Injection type stirring device

A stirring device and a jetting technology, applied in the field of machinery, can solve the problems of difficult operation and insufficient stirring, and achieve the effect of simple operation and freedom from splashing around.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

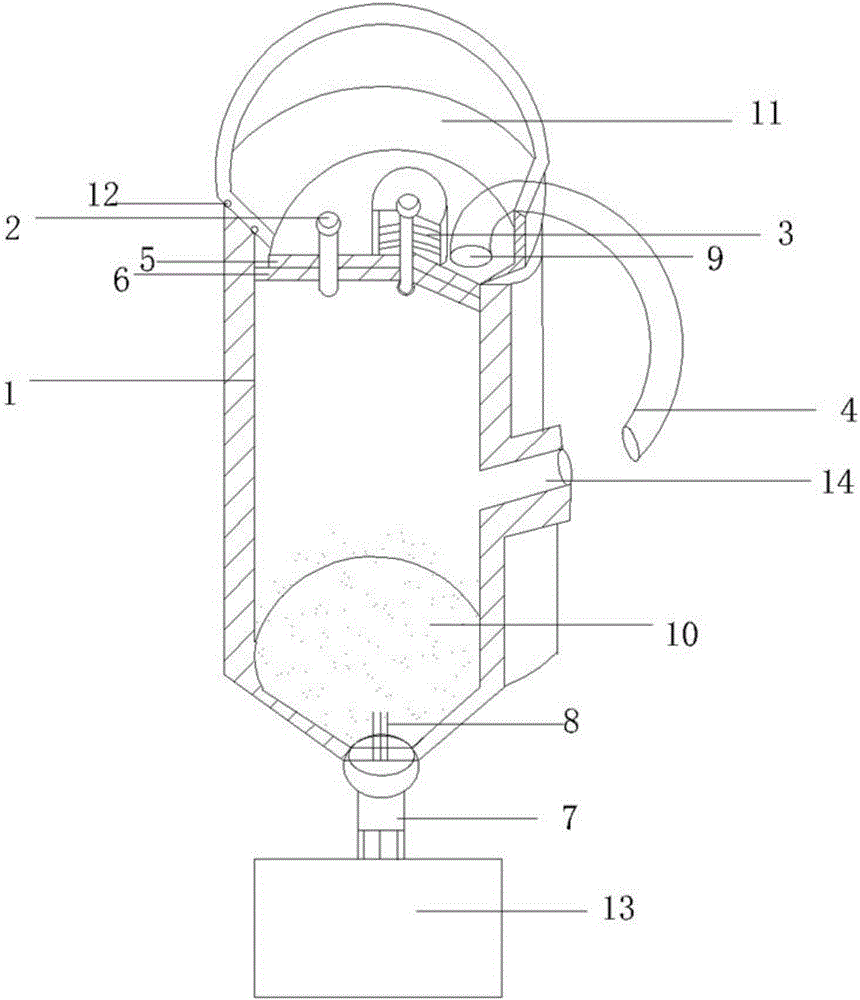

[0014] The reference signs in the drawings of the description include: housing 1, positioning pin 2, compression spring 3, conduit 4, pressure plate A5, pressure plate B6, air pipe 7, air injection head 8, opening 9, powder 10, hopper 11, Living hinge 12, cylinder 13, chute 14.

[0015] Example basic reference figure 1 Shown: a jet stirring device, including a housing 1, a conduit 4 and an air pipe 7, the upper end of the housing 1 is connected to a hopper 11 through a living hinge, and the bottom of the hopper 11 and the top of the housing 1 are respectively arranged There are a pressure plate A5 and a pressure plate B6, the pressure plate A5 and the pressure plate B6 are provided with a compression spring 3 and a positioning sheath 2, and the pressure plate A5 and the pressure plate B6 are respectively provided with corresponding openings 9, and the air pipe 7 is arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap