Preparation method of modified zeolite and modified zeolite prepared by method

A modified zeolite and modification technology, which is applied in chemical instruments and methods, silicate, inorganic chemistry, etc., can solve the problems of high modification cost, collapse of internal structure, expensive raw materials, etc., and achieve reduction of material cost and personnel cost , improved adsorption performance, and simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Weigh several grams of NaCl into a watch glass, place in a drying oven, set the temperature at 105°C, and dry to constant weight. Use the dried above-mentioned crystals to prepare 500 mL of solutions with 0.1 mol / L and 1 mol / L concentrations respectively.

[0041] The zeolite and the above-mentioned prepared inorganic salt solution are transferred into a 250mL conical flask according to a solid-to-liquid ratio of 1:30 (g / mL), covered with a stopper, and transferred to a constant temperature oscillating pot, and the temperature is set at 60°C. at 150r·min -1 rate of oscillation. Take out the Erlenmeyer flask at 1 hour, rinse it repeatedly with deionized water, place it in an oven after rinsing, adjust the drying temperature to 105° C., and dry until constant weight. Carefully take out the dry zeolite sample, put it into a plastic bag, and label it, so that only inorganic salt-modified zeolite samples can be obtained.

[0042] The SEM picture of natural zeolite and the ...

Embodiment 2

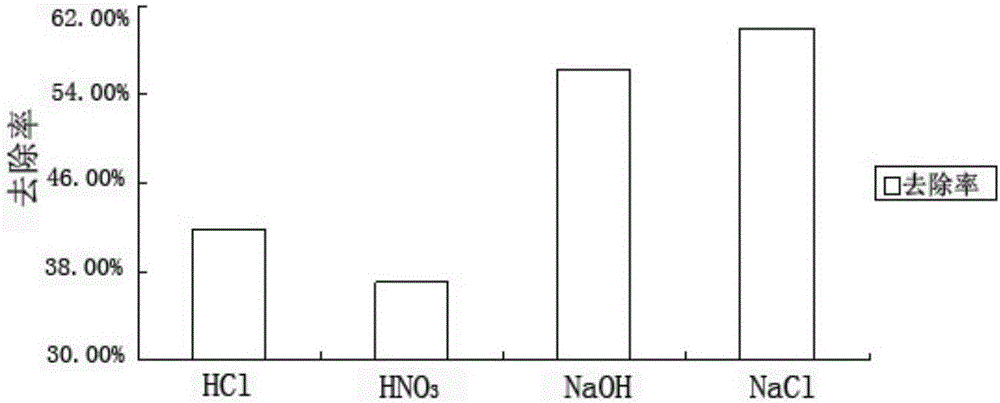

[0057] With reference to the steps of Example 1, an orthogonal experiment was carried out to the zeolite mesh number, salt reagent, modified activation solution concentration, activation time, activation temperature and activation solid-to-liquid ratio, and the same method as in Example 1 was adopted for the measurement of the modified zeolite.

[0058] Use L 9 (3 4 ) orthogonal table, select the above four modification conditions, and set up three gradients respectively, from Table 4: modification time (0.5h, 1h, 1.5h), NaCl concentration (0.2mol / L, 0.4mol / L, 0.6mol / L), solid-to-liquid ratio of zeolite to NaCl solution (1:10, 1:20, 1:30), modification temperature (60°C, 70°C, 80°C). Activate the corresponding zeolite according to the orthogonal table, and activate three copies of the corresponding zeolite (to reduce the influence of activation operation errors on the experimental results).

[0059] Table 4 Gradient Classification of Orthogonal Optimization Modification Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com