Die-casting mould for automobile filter shell body

A technology of filters and die-casting molds, which is applied in the field of casting, can solve the problems of poor crystallization and compactness of castings, and easy generation of pores, etc., and achieve the effect of reasonable distribution, good compactness, and not easy to produce pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

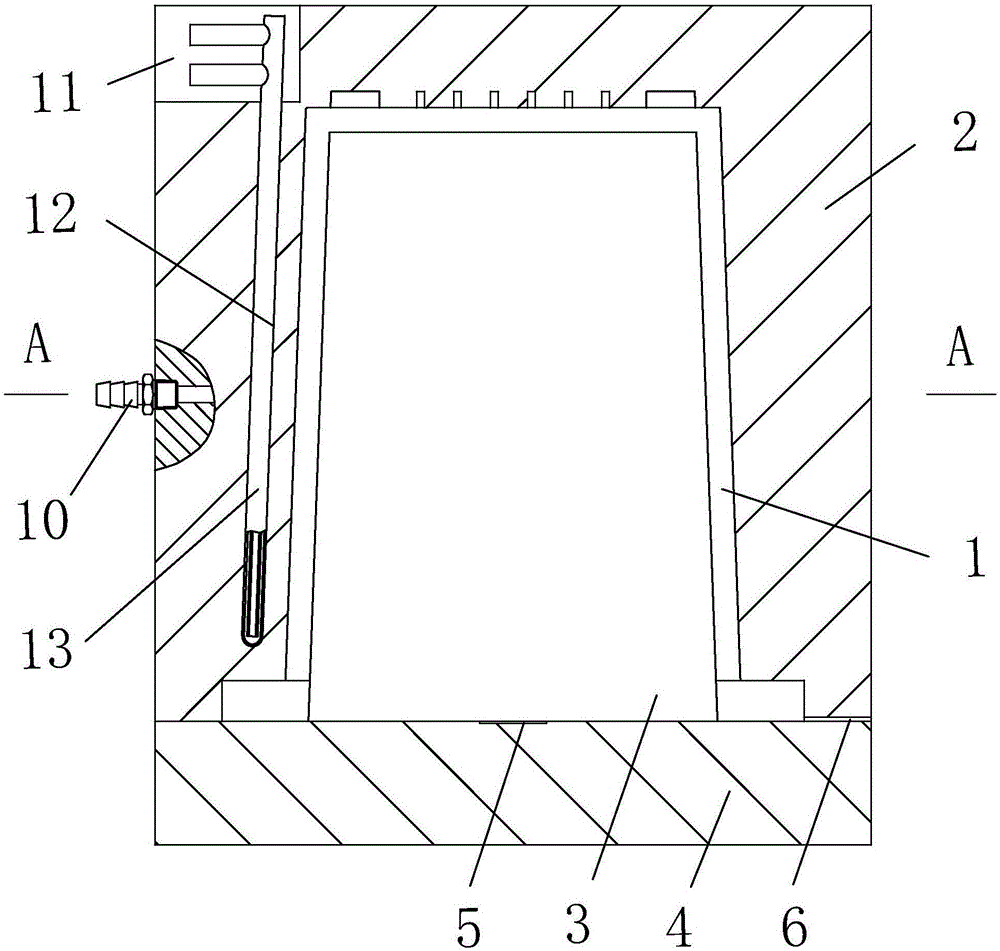

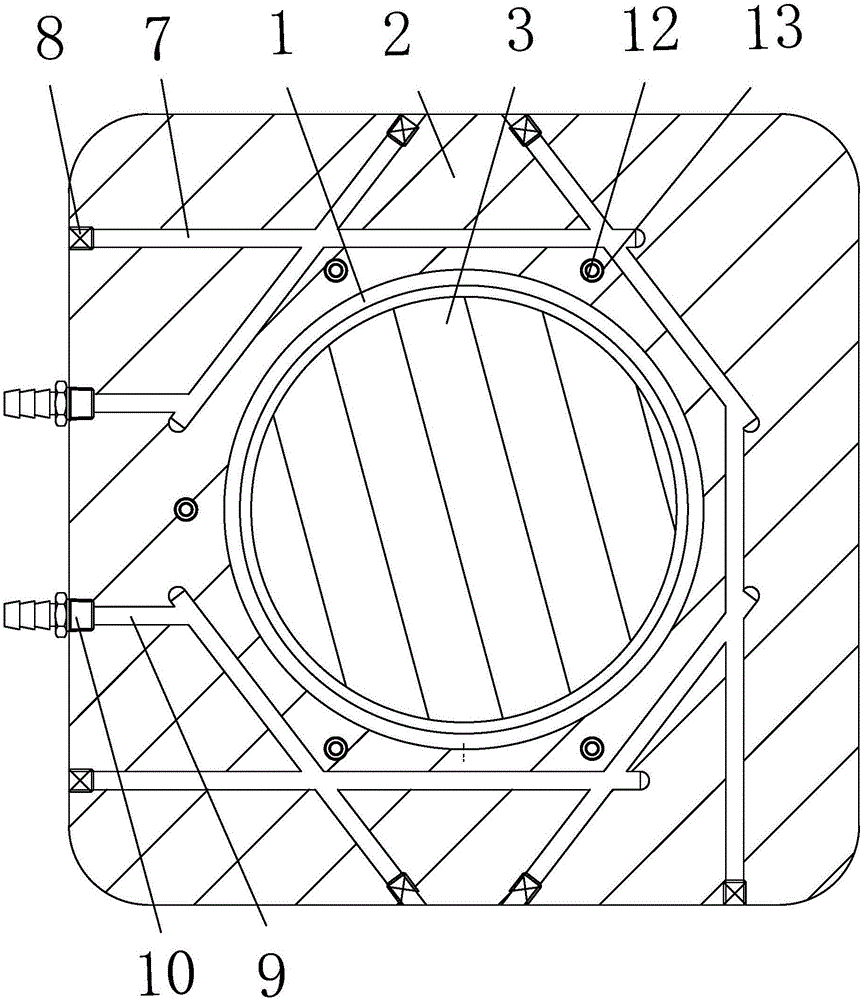

[0013] as attached figure 1 , attached figure 2 Shown: a die-casting mold for an automobile filter housing, including: an upper mold 2 with a cavity 1, a lower mold 4 with a core 3, a gating system 5 connected to the cavity 1, and an exhaust channel 6 , the annular cooling assembly and the point cooling assembly located outside the side wall of the cavity 1.

[0014] The annular cooling assembly includes: seven straight cooling channels 7 located in the middle of the outer side of the cavity 1 and connected in sequence, the number of plugs 8 is the same as the number of straight cooling channels 7, two one ends are connected to the side of the upper mold 2 A connecting passage 9 and two connecting joints 10; one end of the straight cooling passage 7 is connected with the side of the upper mold 2; the plug 8 corresponds to the straight cooling passage 7 and blocks one end of the straight cooling passage 7; one connecting The other end of the road 9 communicates with the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com