Patents

Literature

31results about How to "Uniform cooling and cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

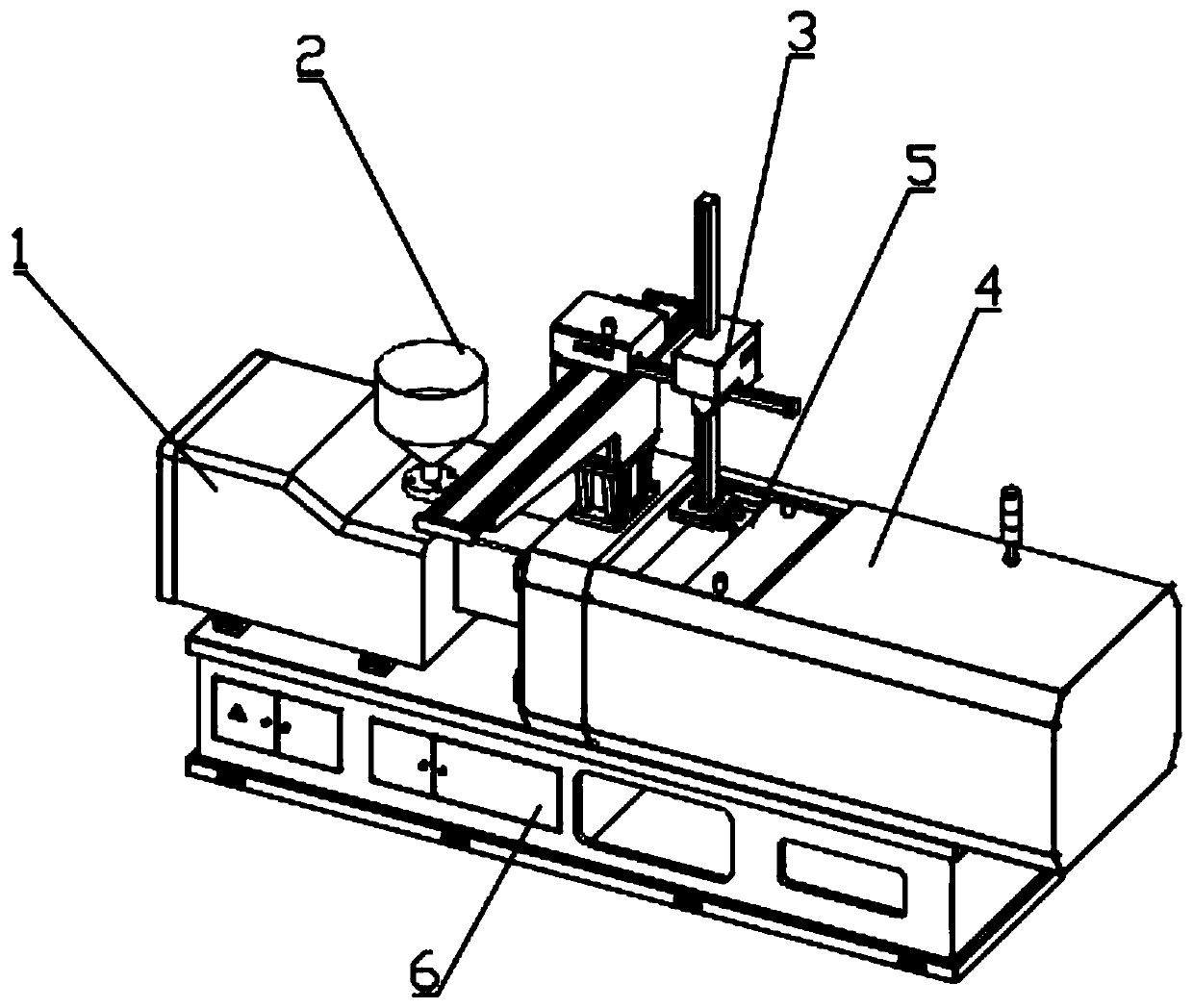

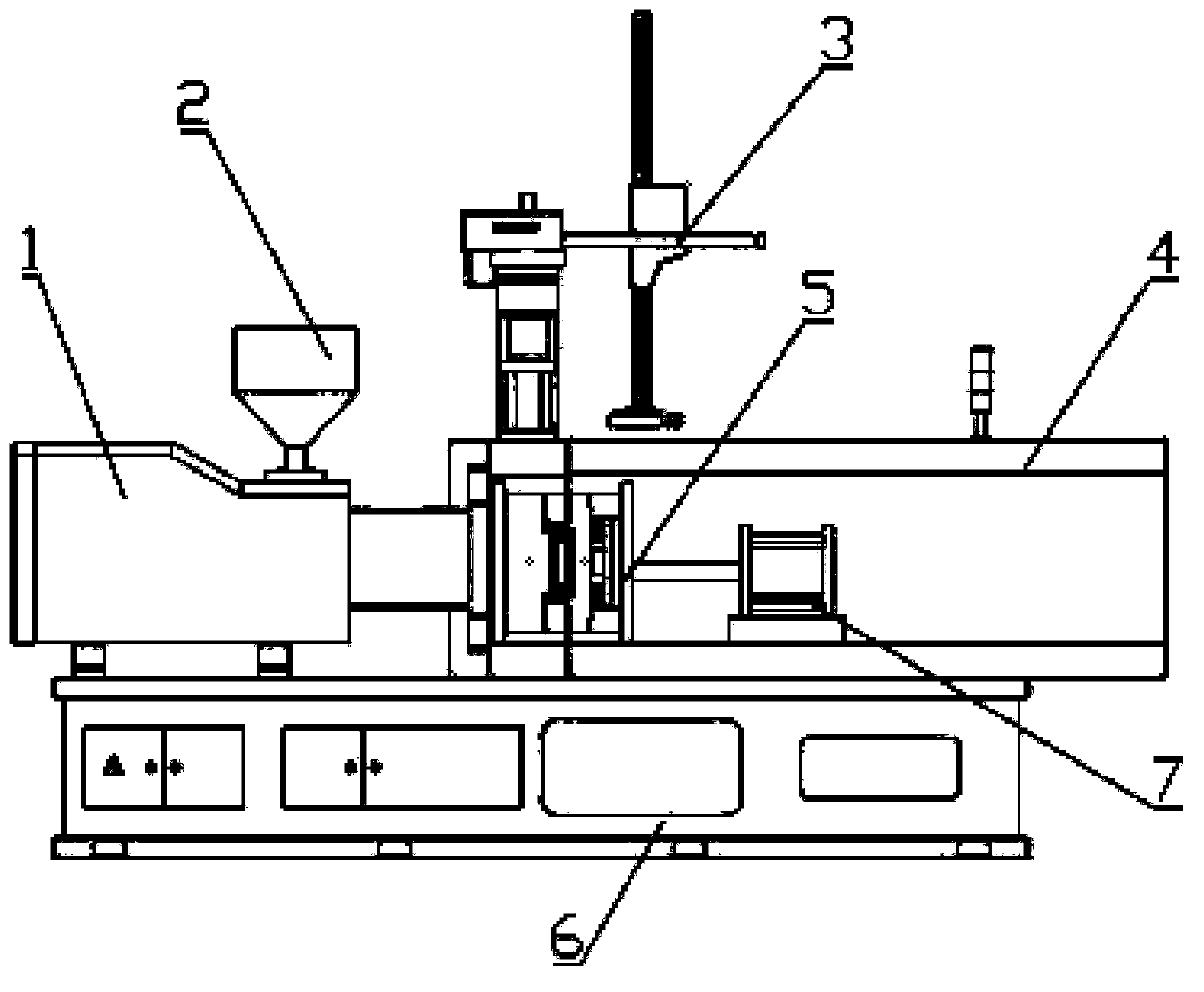

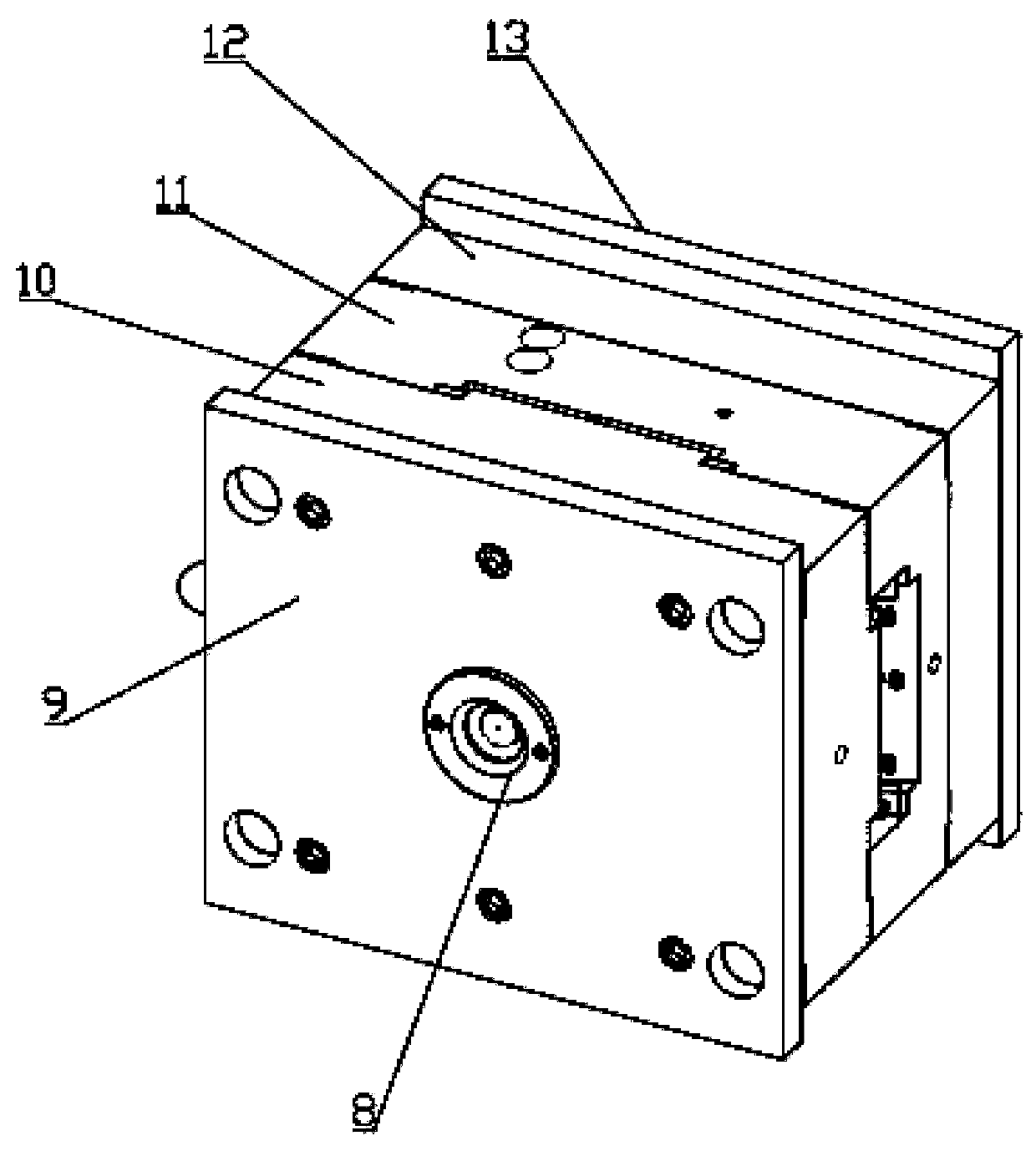

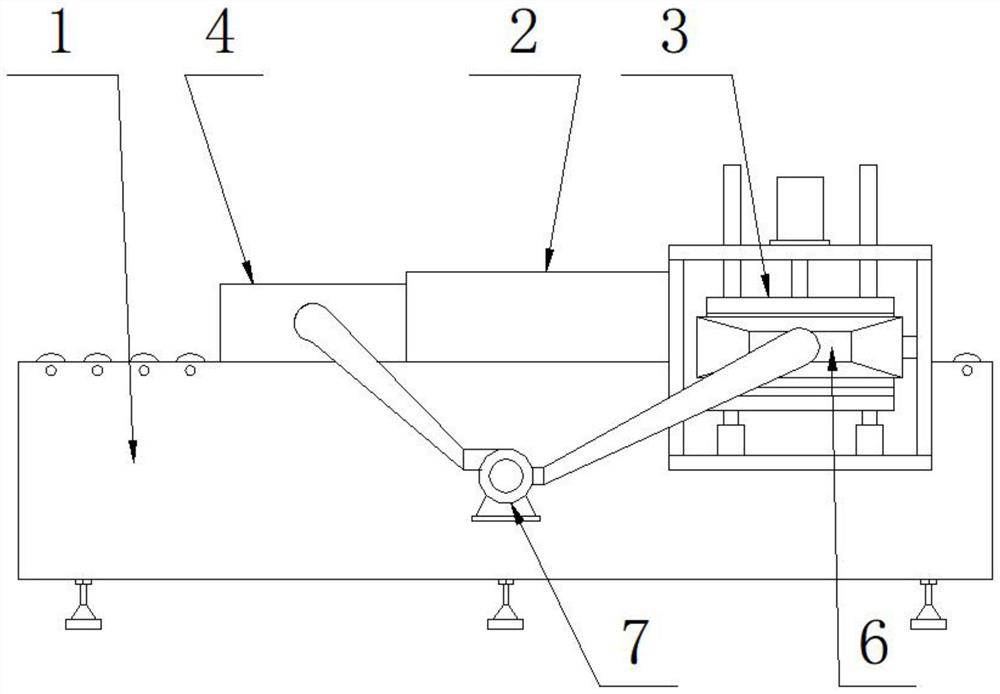

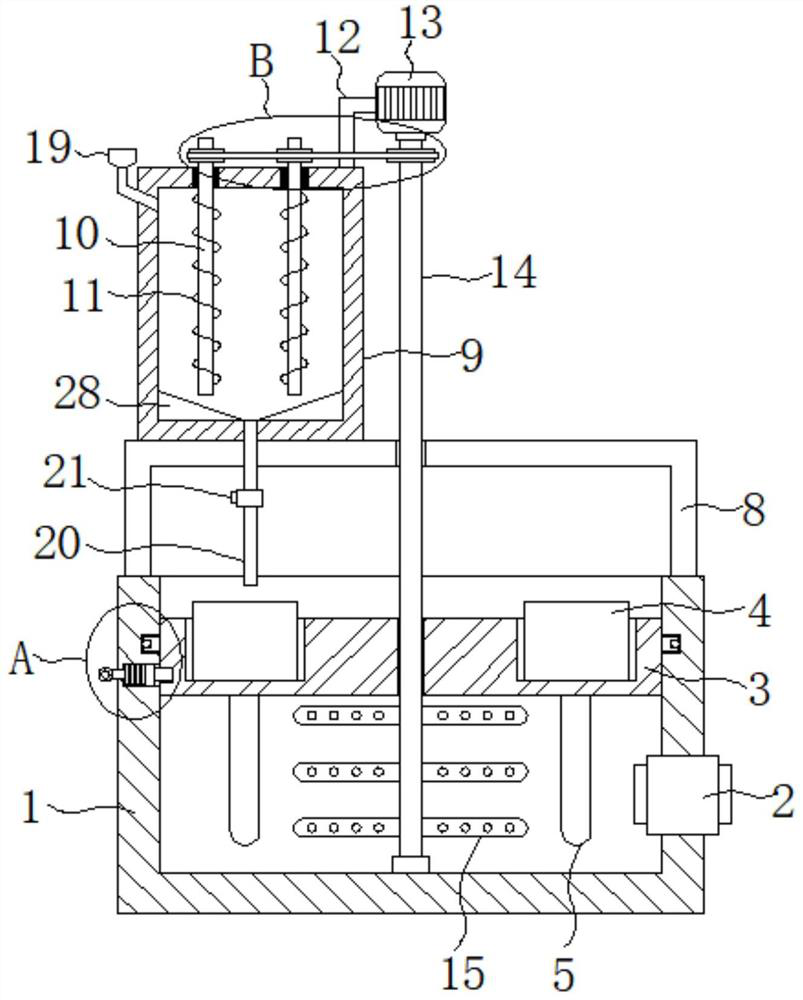

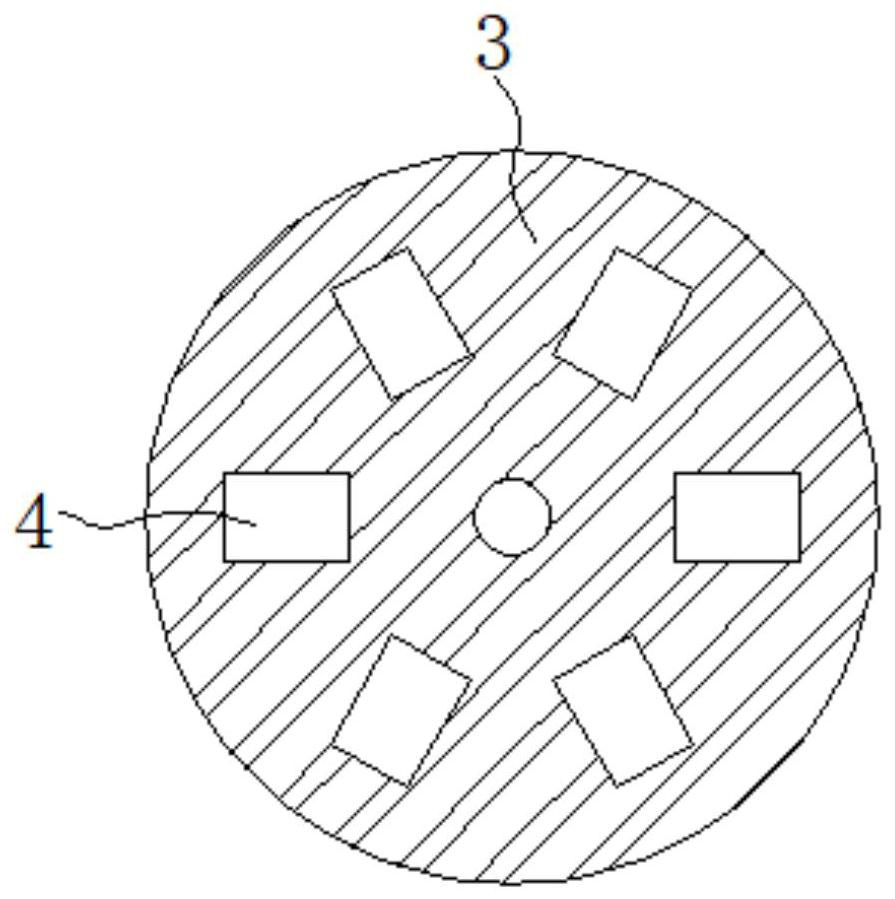

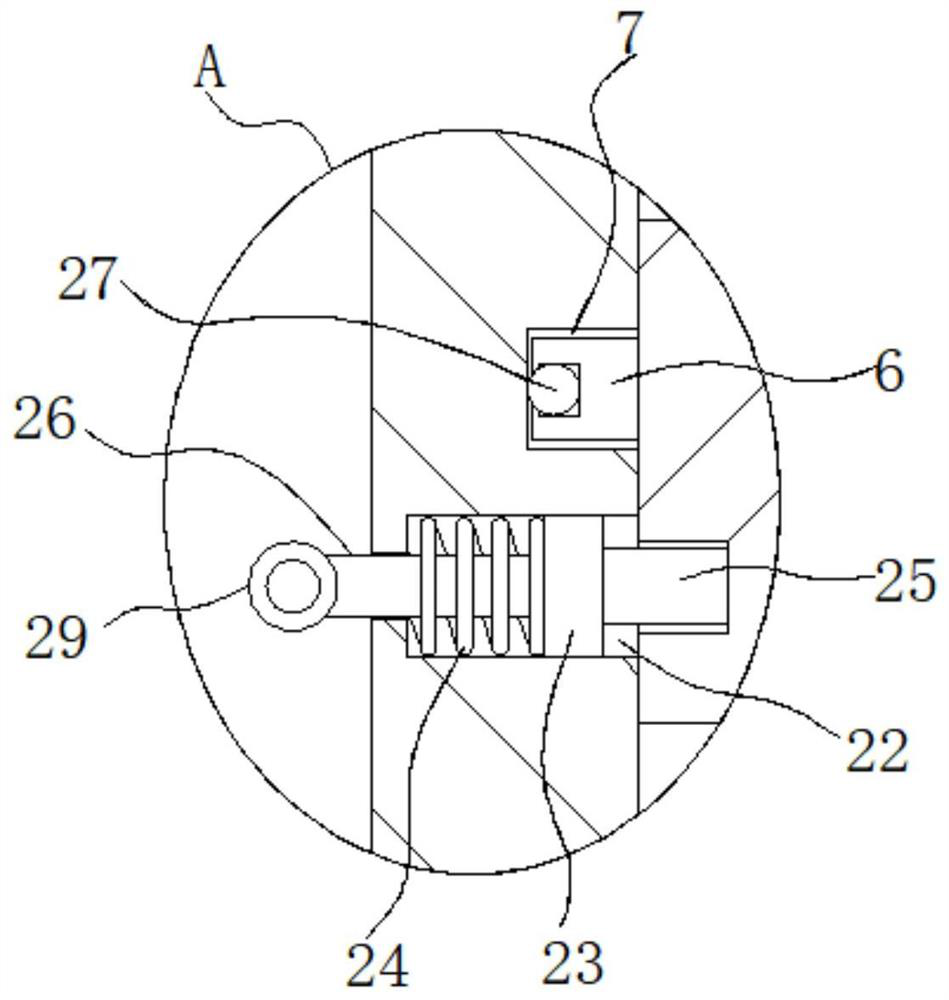

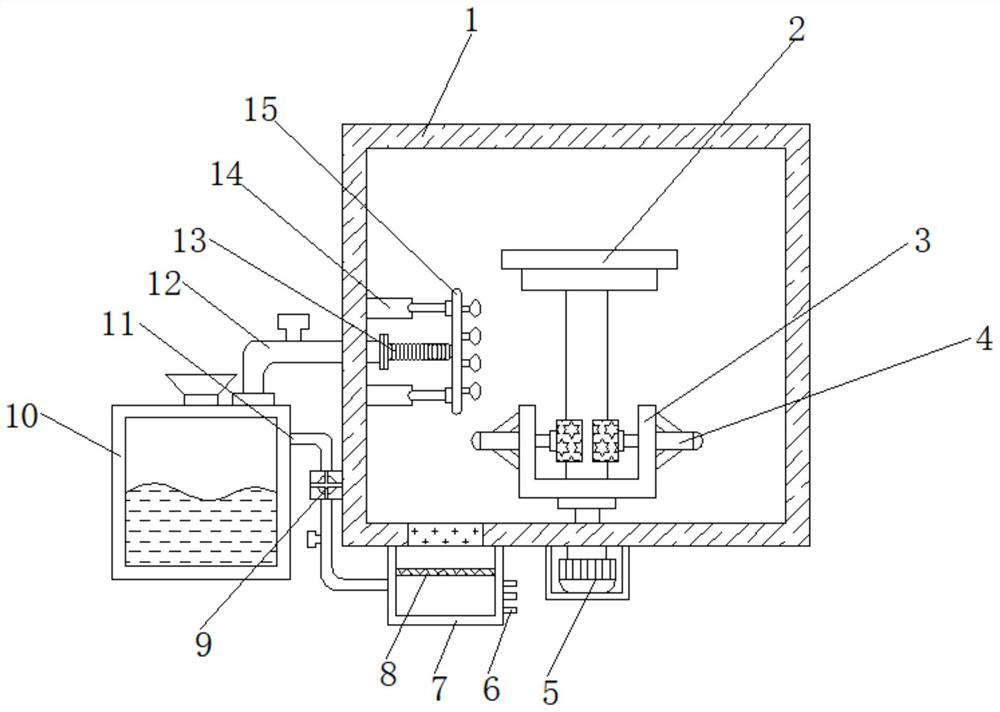

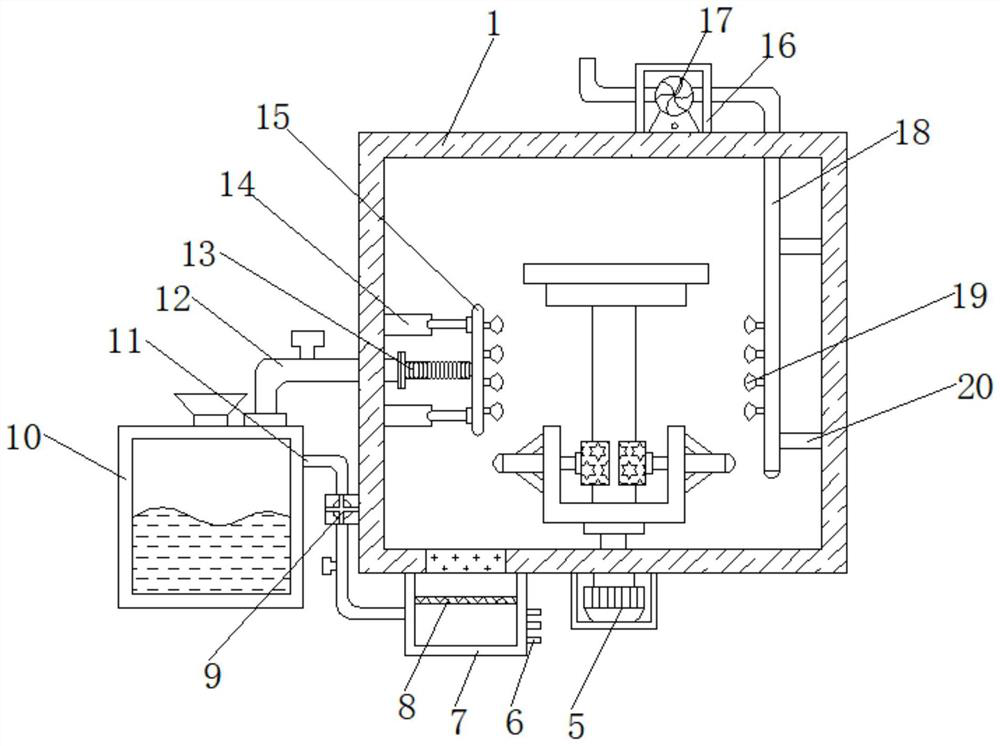

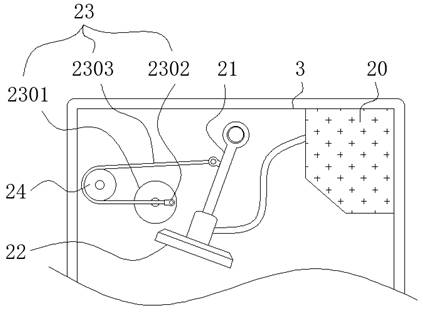

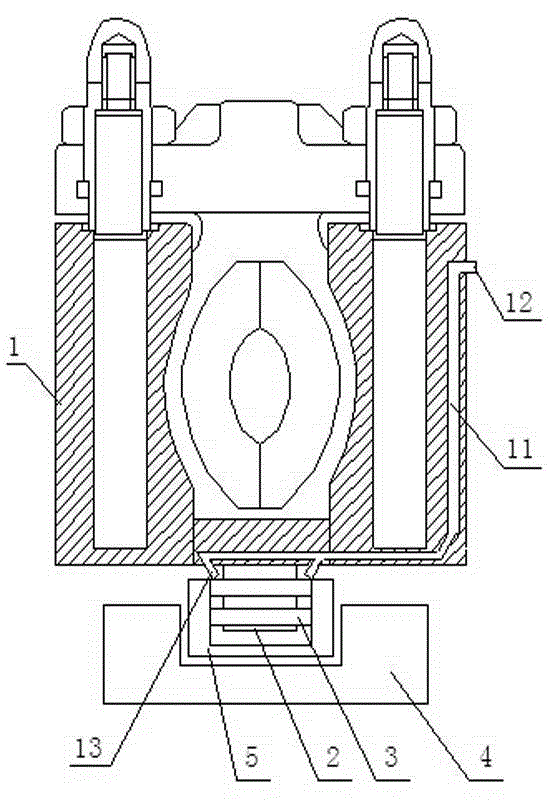

Injection molding mechanism for fast blanking and operation method thereof

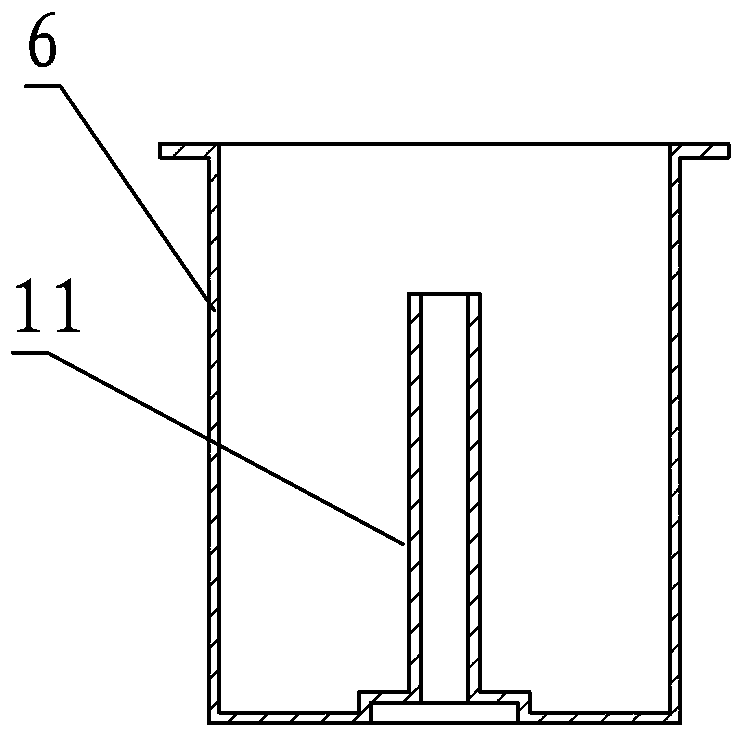

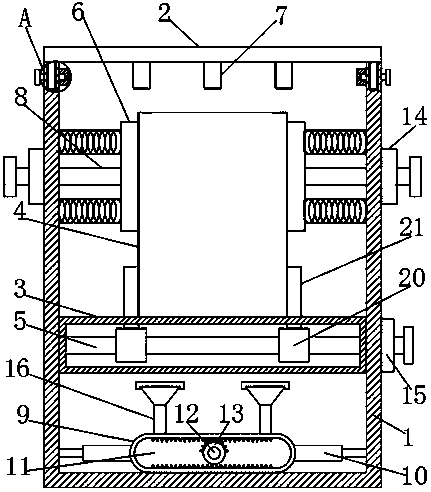

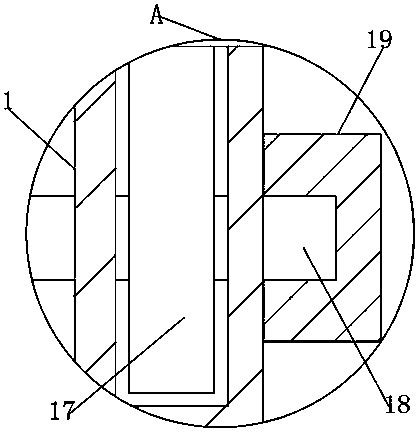

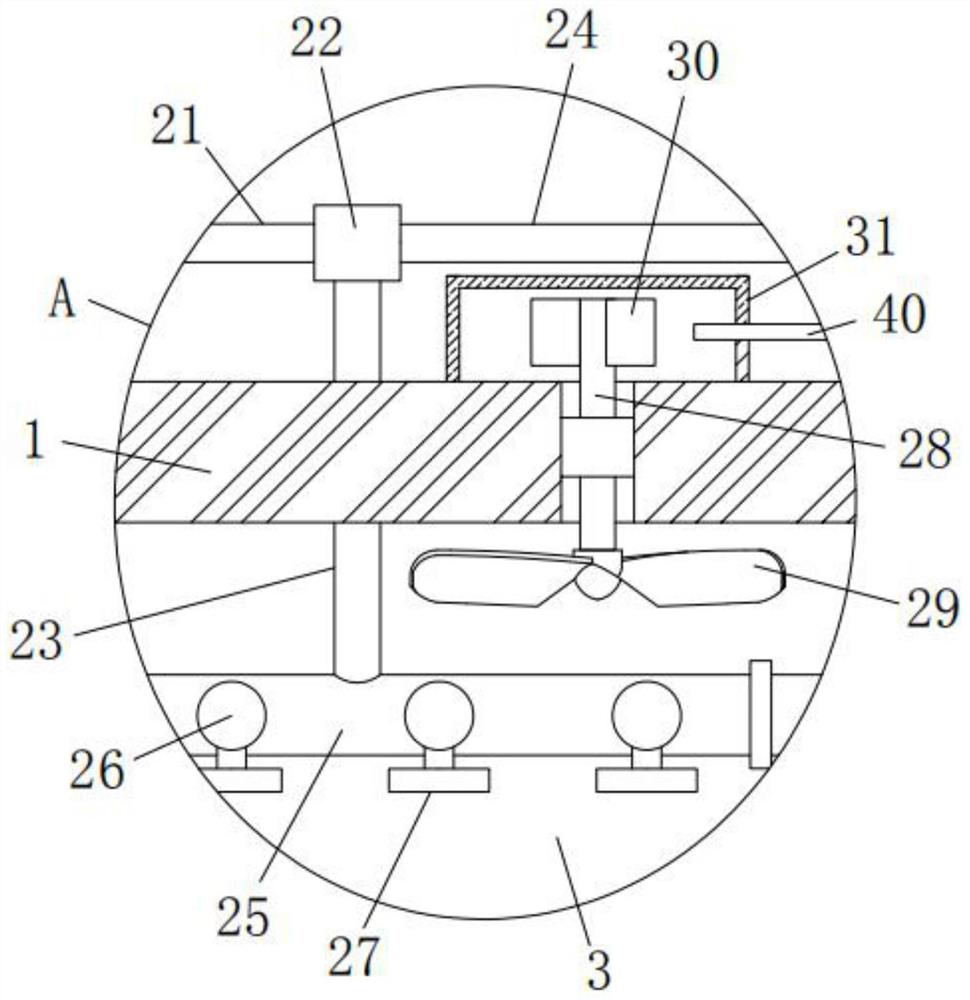

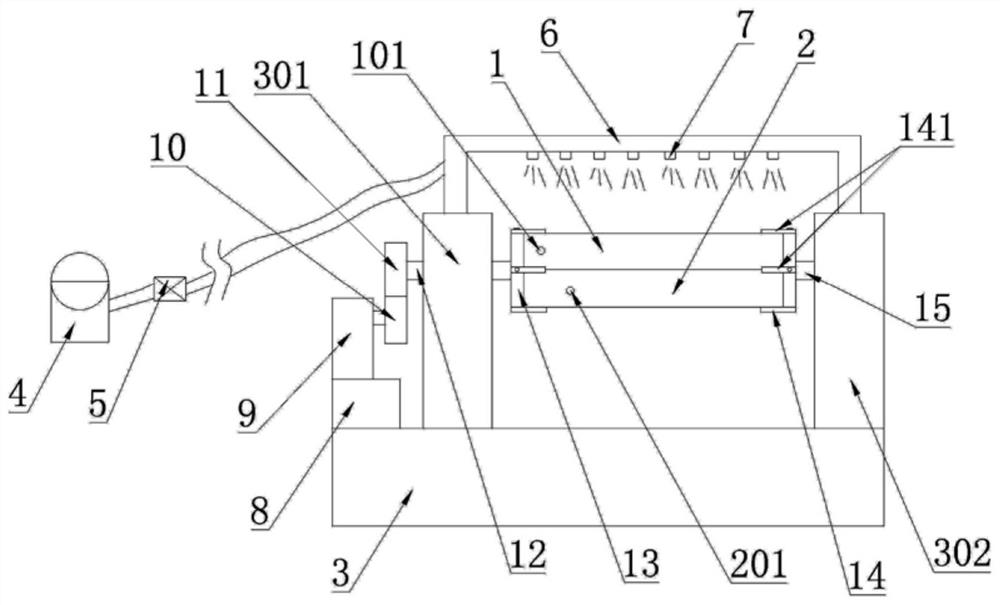

The invention discloses an injection molding mechanism for fast blanking. The injection molding mechanism comprises a feeding box, an injection molding box and an injection molding device, the feedingbox is arranged on one side of the top surface of a base, the injection molding box is arranged on the other side of the top surface of the base, a feeding funnel is arranged on the top surface of the feeding box, the feeding end on one side of the injection molding device communicates with the feeding box, and the other side of the injection molding device is connected with the output end of a hydraulic cylinder; the hydraulic cylinder is installed on the inner bottom surface of the injection molding box; and a fixed die fixing plate is arranged on the inner wall of the injection molding box, a fixed die is arranged on the side wall, far away from the feeding box, of the fixed die fixing plate, one side of a movable die fixing plate is connected with the output end of the hydraulic cylinder, an ejection plate is arranged on the other side of the movable die fixing plate, a movable die matched with a fixed die is arranged on the other side of the ejection plate, a guide rod is arranged on the side wall, close to the movable die, of the fixed die, and an ejection mechanism is arranged in the ejection plate. The injection molding mechanism has the advantages that the blanking rate is greatly improved, uniform die cooling can be realized, the forming efficiency is greatly improved, and automatic material taking is achieved.

Owner:林冰莺

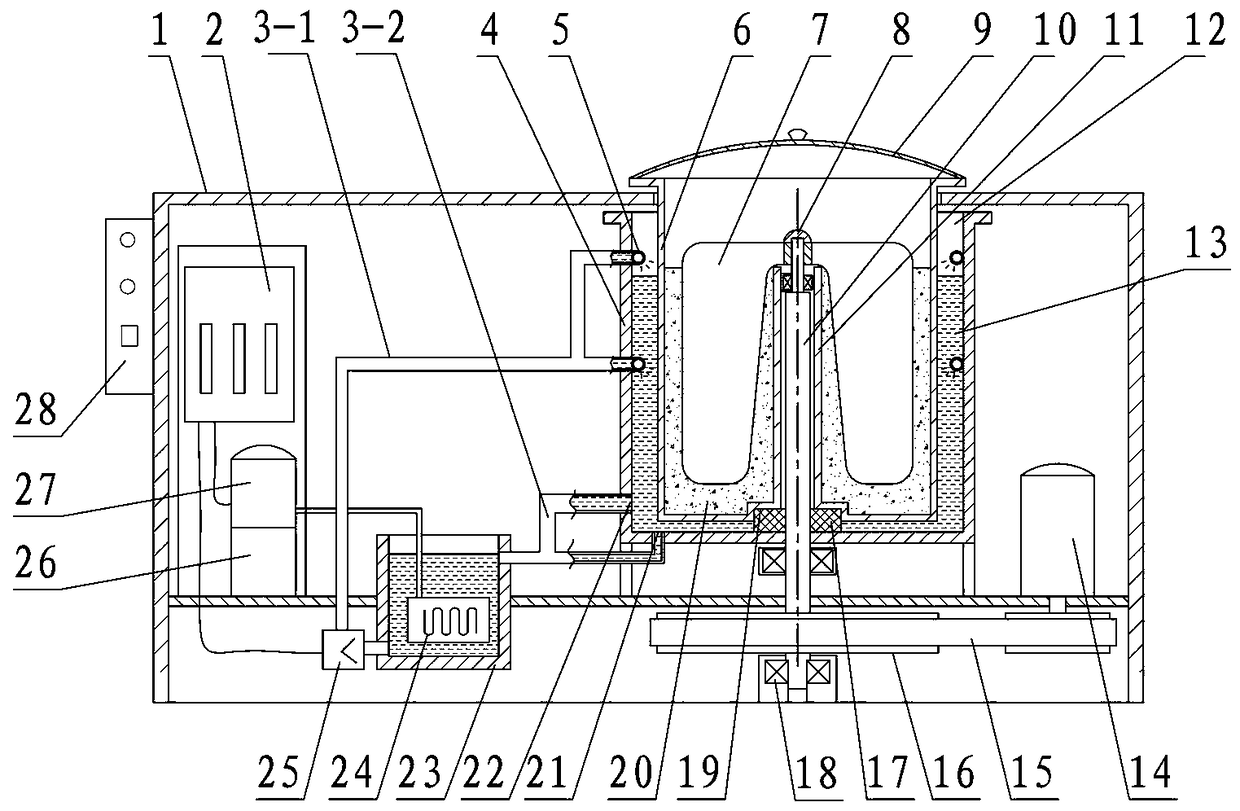

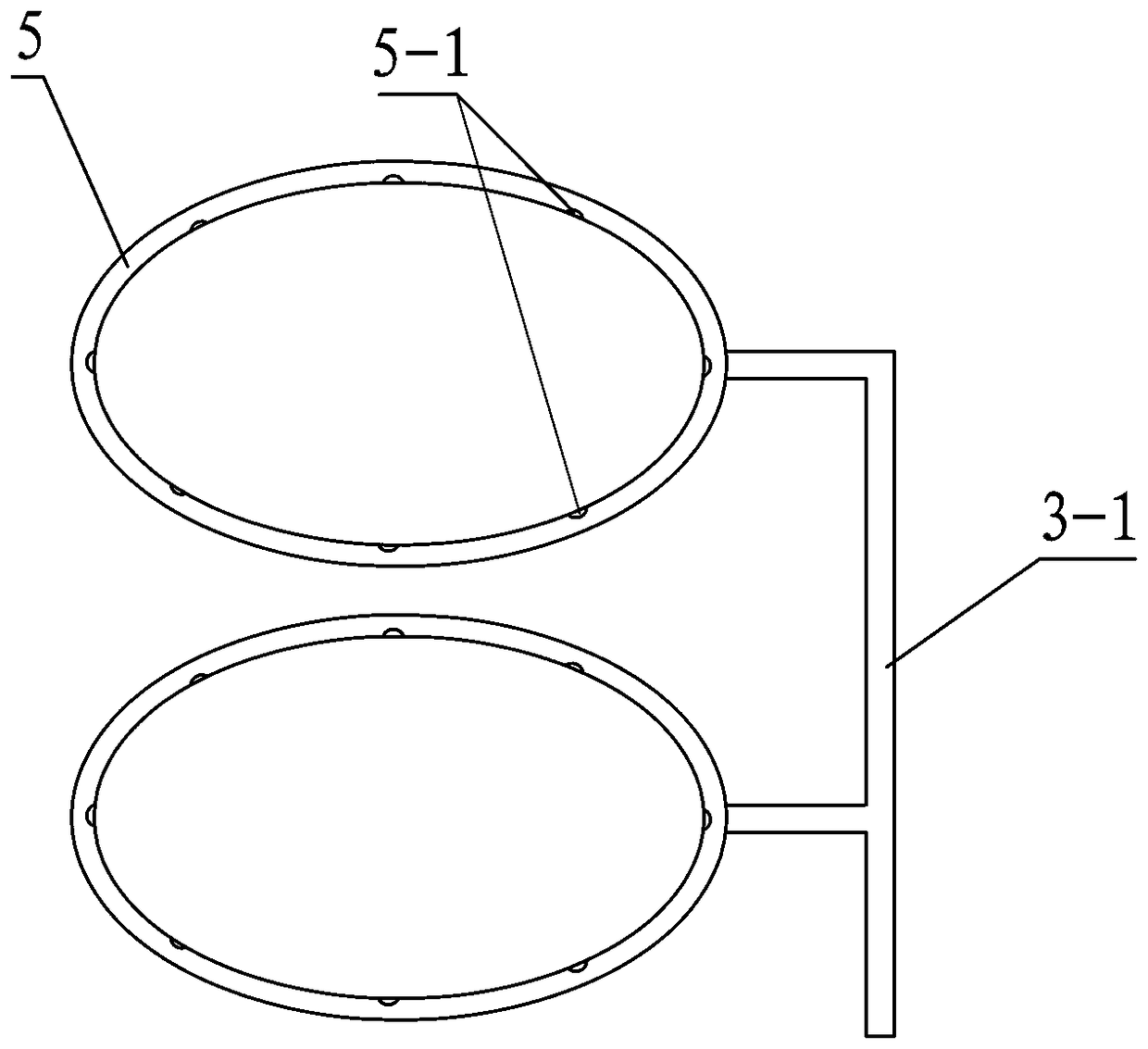

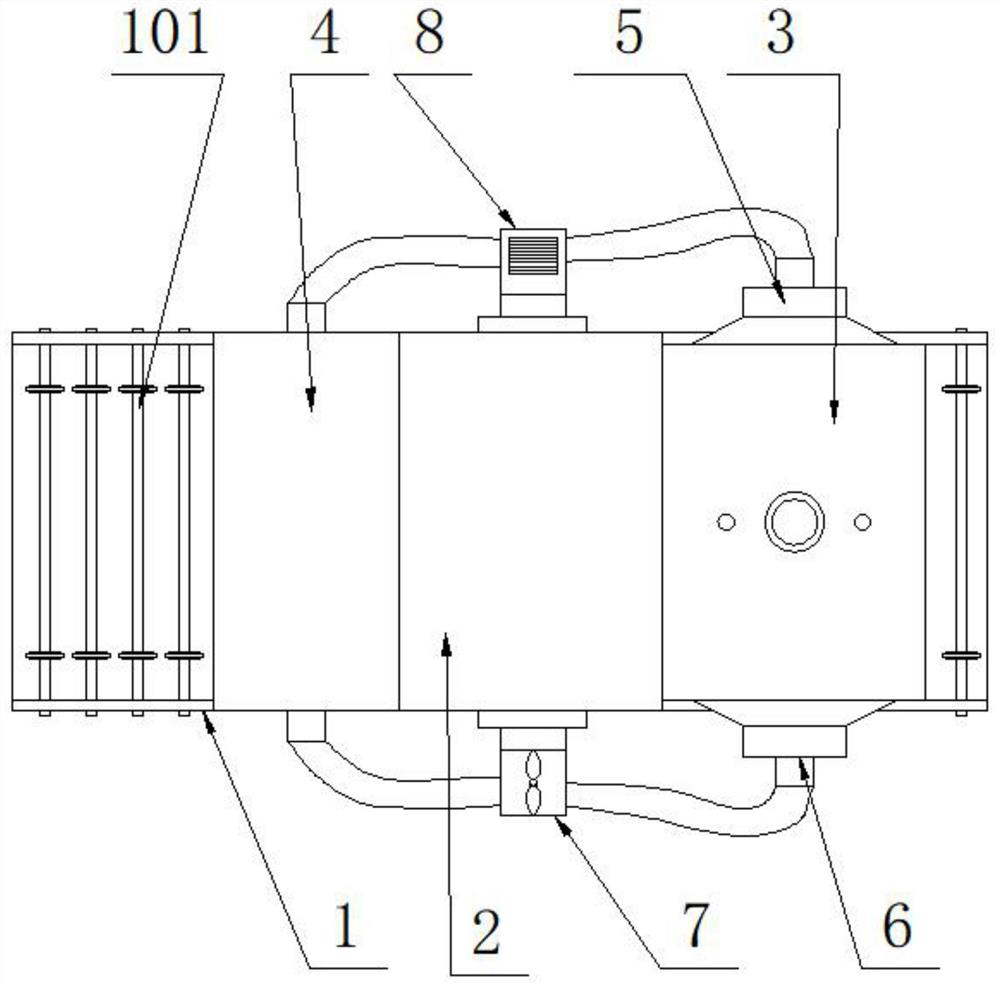

Separable anti-cylinder freezing ice cream machine

PendingCN108514044ARapid Cooling and RefrigerationUniform cooling and coolingFrozen sweetsHigh energyEvaporation

The invention provides a separable anti-cylinder freezing ice cream machine, and solves the problems that conventional ice cream machines with an inner and outer barrel type structure are liable to cylinder freezing, low cooling speed, uneven cold conduction, difficult cleaning, inconvenient assemble and disassemble, high manufacturing cost and high energy consumption. The technical scheme is as follows: a refrigeration container comprises an outer barrel and an inner barrel; a coolant circulating storage cavity is reserved between the inner wall and the bottom of the outer barrel and the inner barrel; a coolant spray pipe with a plurality of spray ports is arranged on the inner wall of the outer barrel; a coolant storage pool is also arranged at the lower part of a frame; an evaporation pipe of a refrigeration system is arranged in the coolant storage pool; and between the coolant circulating storage cavity and the coolant storage pool, coolant circulation pipelines are formed by communicating the coolant spray pipe and liquid guide pipes with a circulating pump. The machine can prevent the phenomenon of cylinder freezing, is convenient to assemble and disassemble and easy to clean, can work simultaneously with single cylinder or multi-cylinders, has low energy consumption, can manufacture ice cream with a plurality of tastes at the same time, realizes the integration of storefront production and display, and replaces an air-cooled display cabinet.

Owner:关凯亮

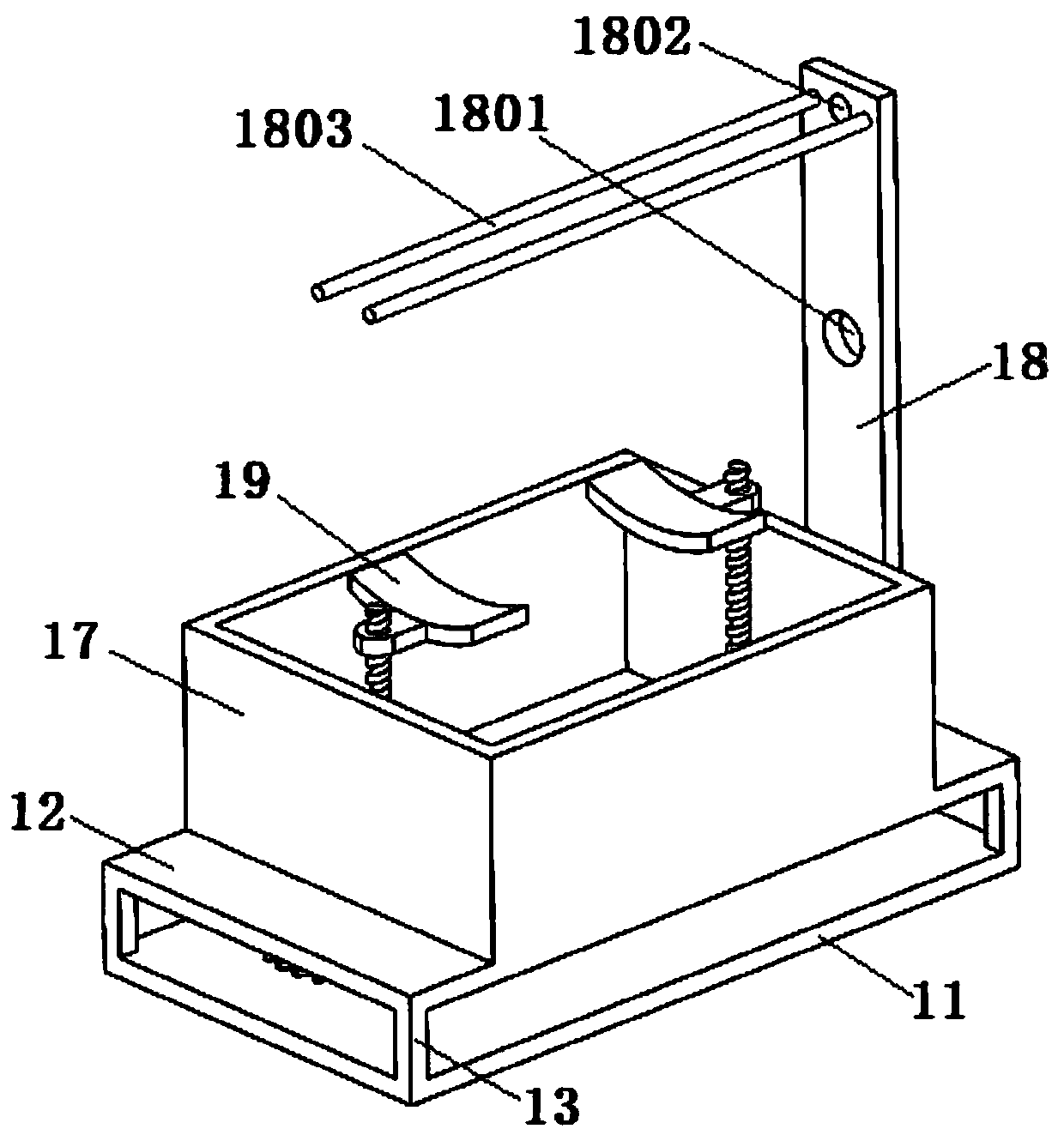

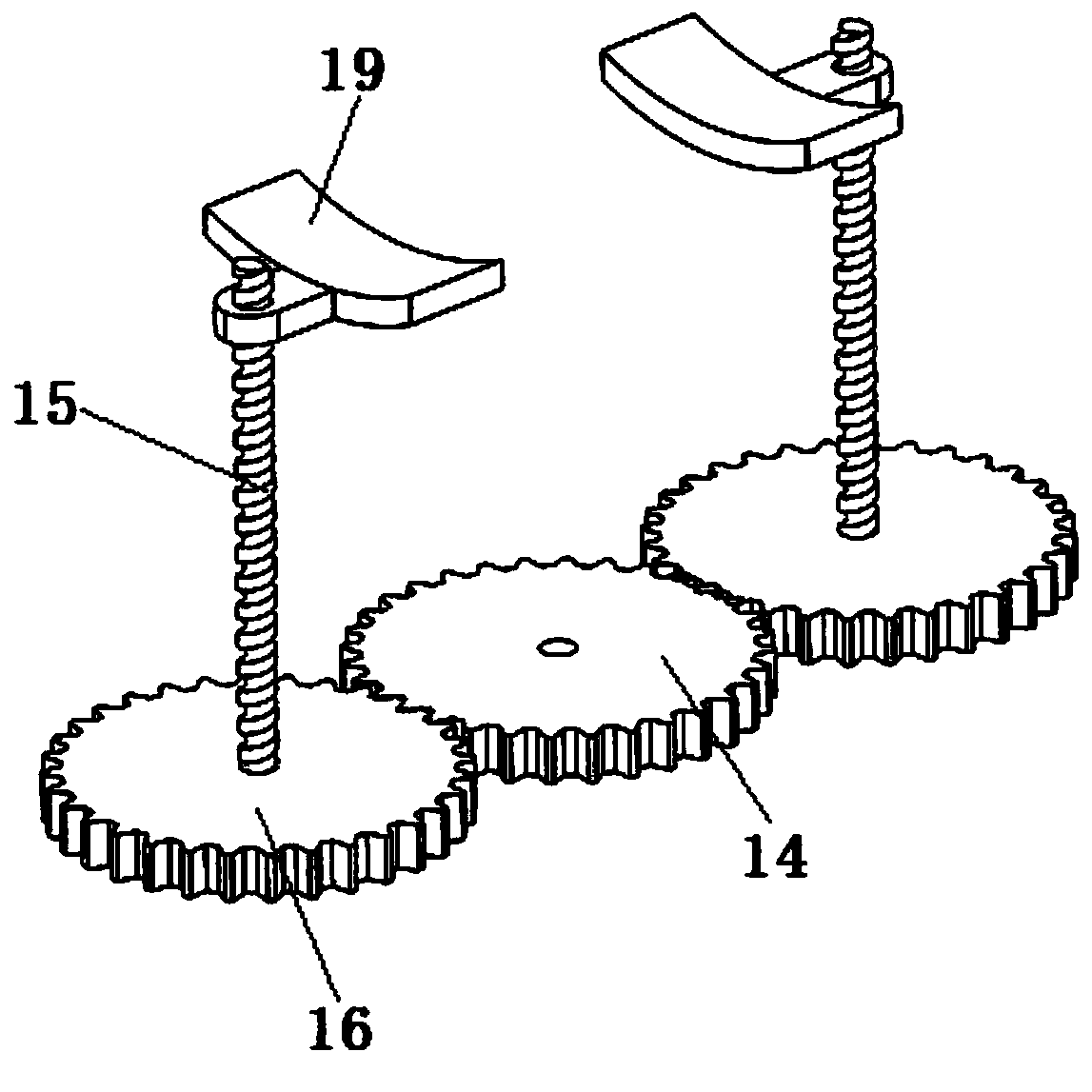

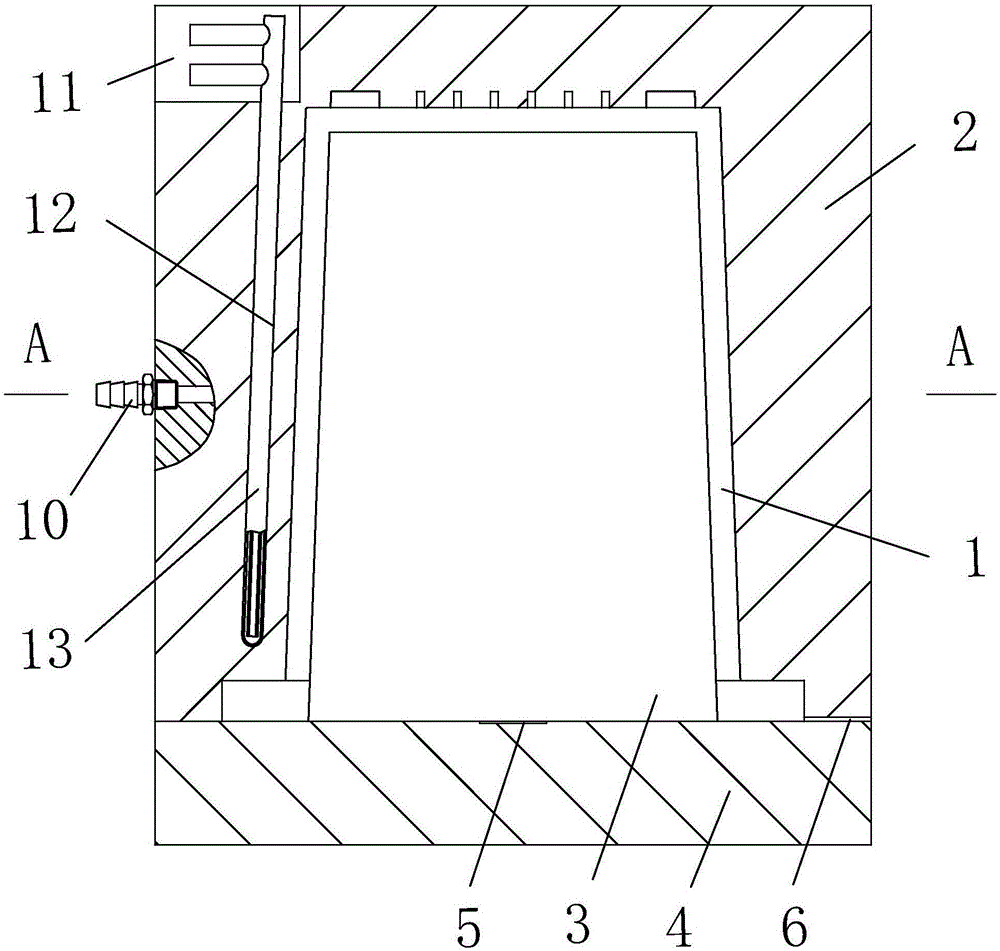

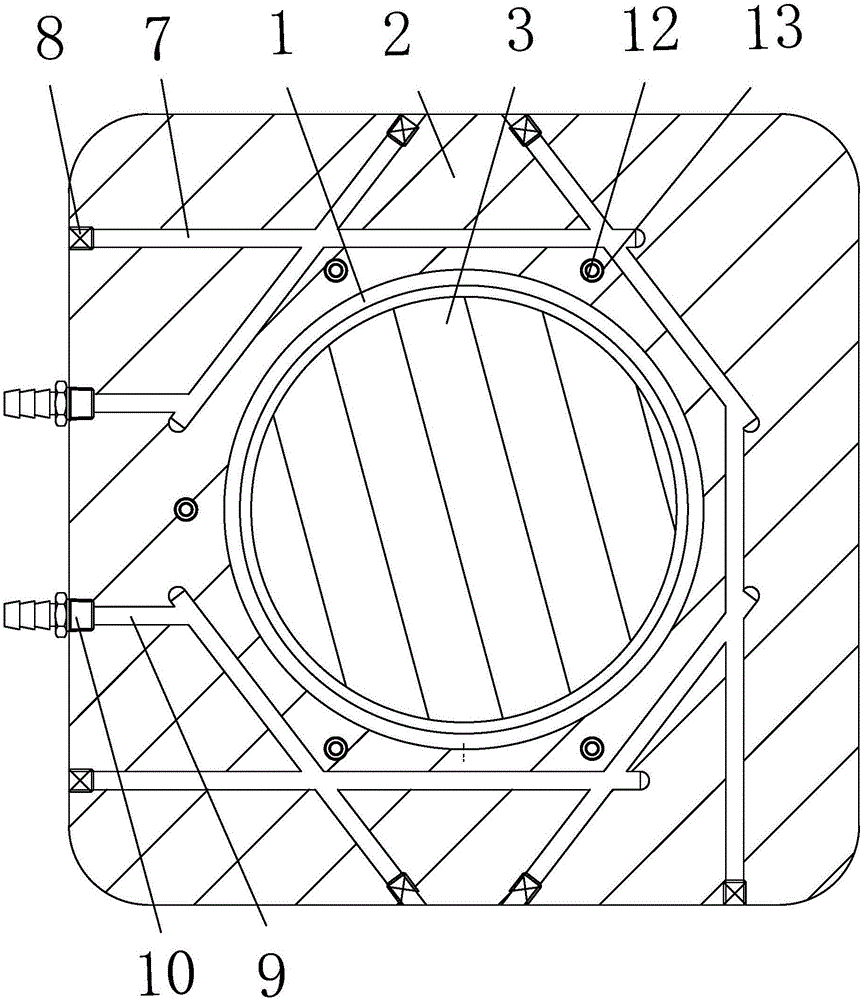

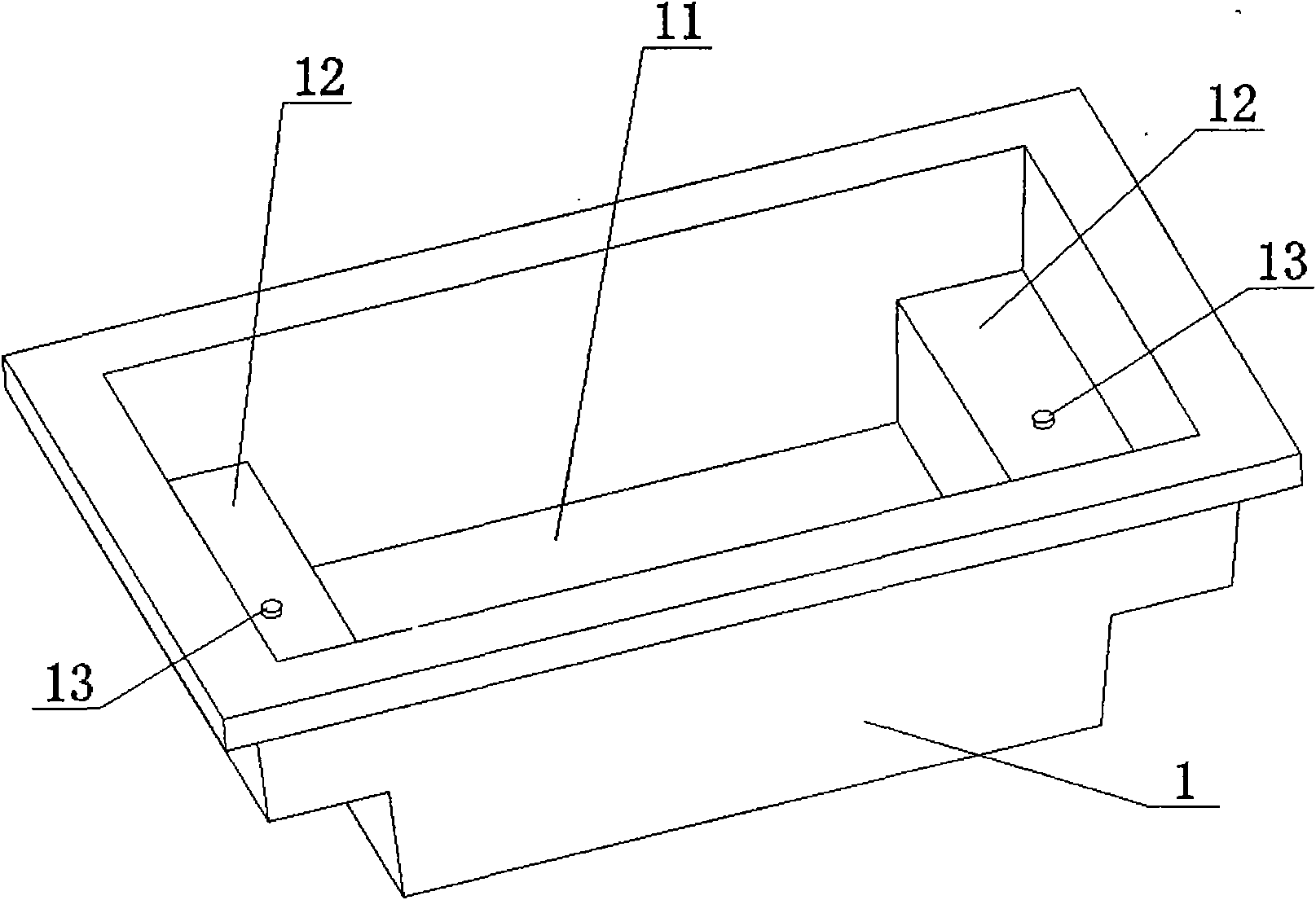

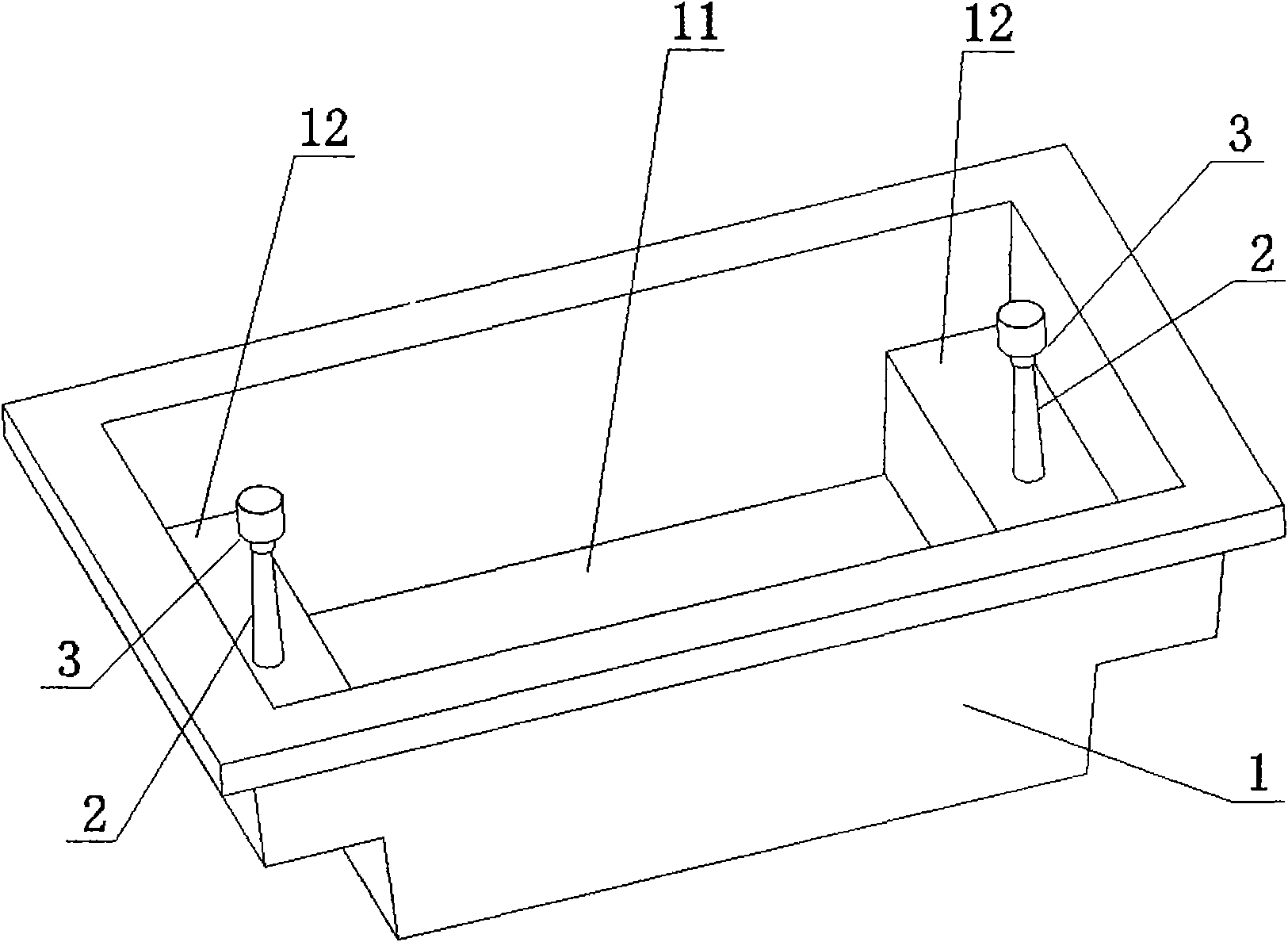

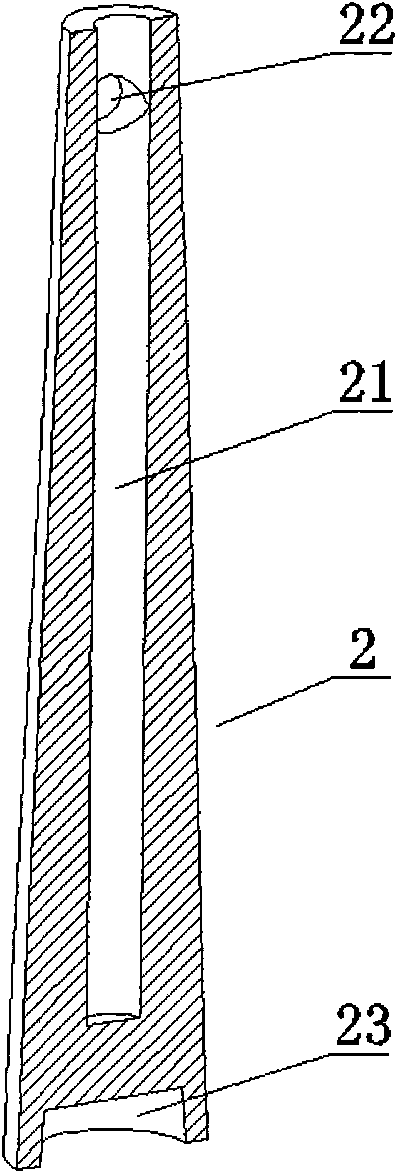

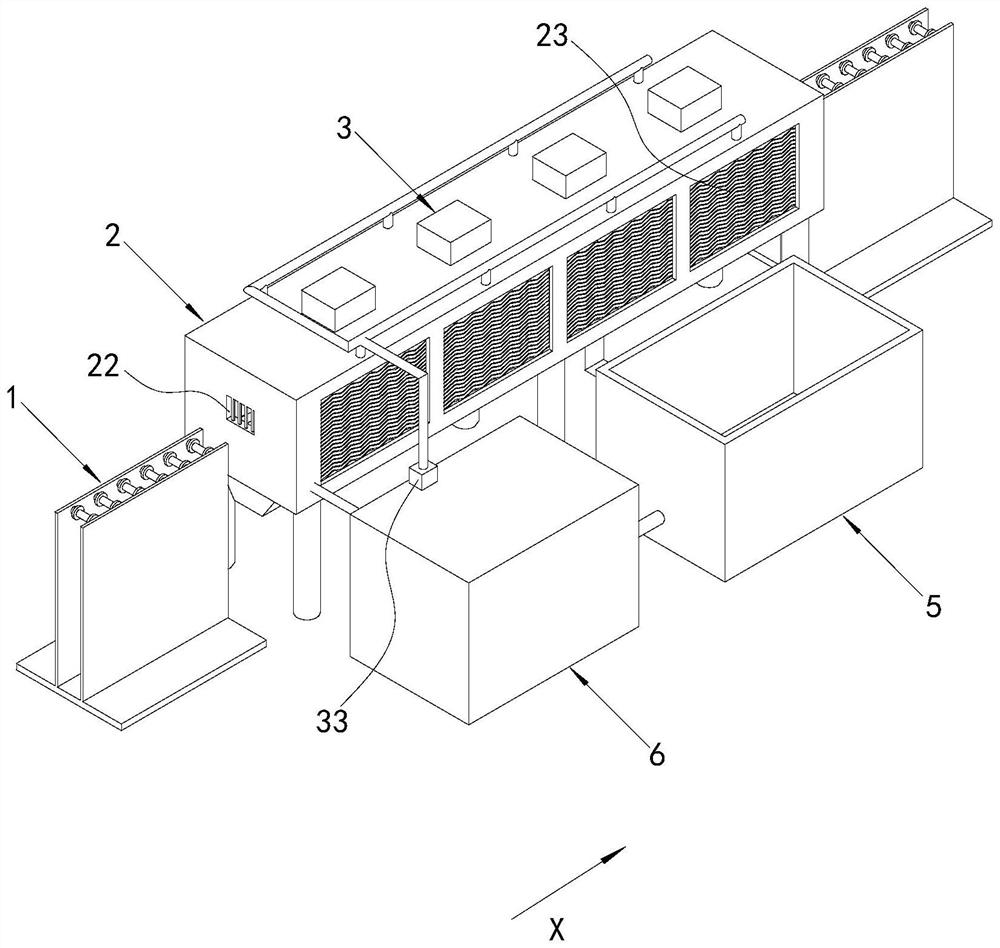

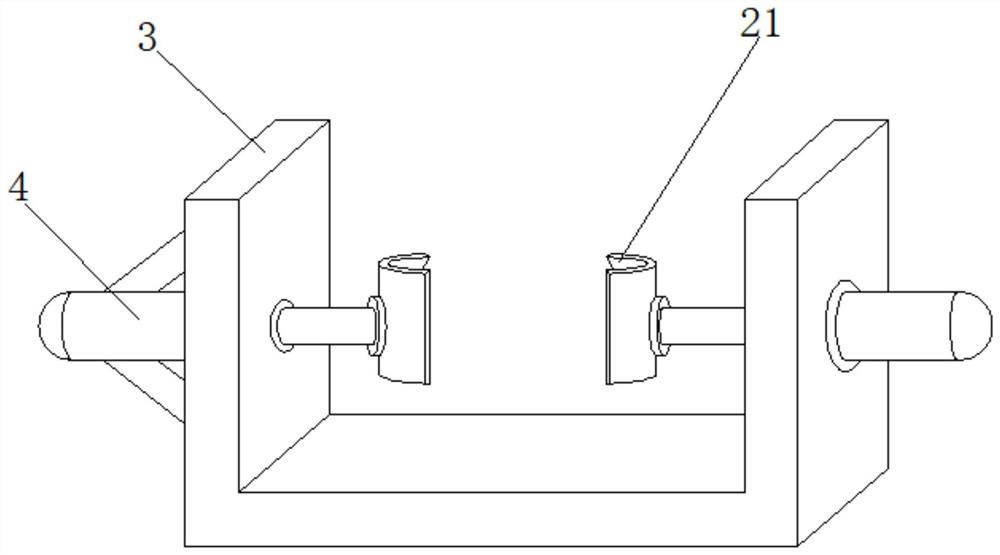

Novel casting sand box

InactiveCN108526415AStable working conditionPlaced in a stable stateMoulding flasksEngineeringThreaded rod

The invention discloses a novel casting sand box which comprises a box body. A through hole communicating with the outside is formed in the upper end of the box body; a box cover is arranged on the opening part of the through hole; multiple cooling devices are fixedly connected to a lower side wall of the box cover; a horizontally arranged placement plate is arranged in the box body; a sand box body is arranged on the placement plate; the placement plate is of a hollow structure; a first threaded rod arranged horizontally is arranged in the placement plate; one end of the first threaded rod isrotatably connected with one side inner wall of the placement plate; the other end of the first threaded rod penetrates through one side wall of the box body; two symmetrically arranged nuts sleeve on the first threaded rod; vertically arranged clamping plates are fixedly connected onto the two nuts; and strip-shaped through holes matched with the clamping plates are formed in one side wall of the placement plate. According to the novel casting sand box provided by the invention, the sand box body can be uniformly cooled, a placement state of the sand box is stable, and the sand box is ensured to work normally.

Owner:盐城恒鼎机械有限公司

Application of metallurgical bonding of metal wire with porous material in manufacturing high temperature resistant mechanical part

InactiveCN110566290AEasy to controlIncreased internal surface areaContinuous combustion chamberEngine fuctionsHeat flowWorking environment

The invention discloses application of metallurgical bonding of a metal wire with a porous material in manufacturing a high temperature resistant mechanical part. The metal wire material is collectedtogether to press to enable the metal wires to be in contact with each other; metallurgical bonding between the metal wires is realized to prepare a metal wire porous material with communicating pores; the metal wire porous material is processed into a porous high temperature resistant mechanical part, and the porous high temperature resistant mechanical part is assembled into a mechanical structure to be fixed at a corresponding position; fluid passes by a fluid channel to enter the high temperature resistant mechanical part; fluid reaches the outer surface of the porous high temperature resistant mechanical part from one side of the inner surface of the porous high temperature resistant mechanical part through the pores of the porous high temperature resistant mechanical part; the poroushigh temperature resistant mechanical part is cooled, and a fluid film is formed on the outer surface of the porous high temperature resistant mechanical part to prevent a heat flow from being in direct contact with the porous high temperature resistant mechanical part, so that the porous high temperature resistant mechanical part works at a lower temperature. According to the invention, the service life of the porous high temperature resistant mechanical part under the high temperature working environment can be prolonged.

Owner:SOUTH CHINA UNIV OF TECH

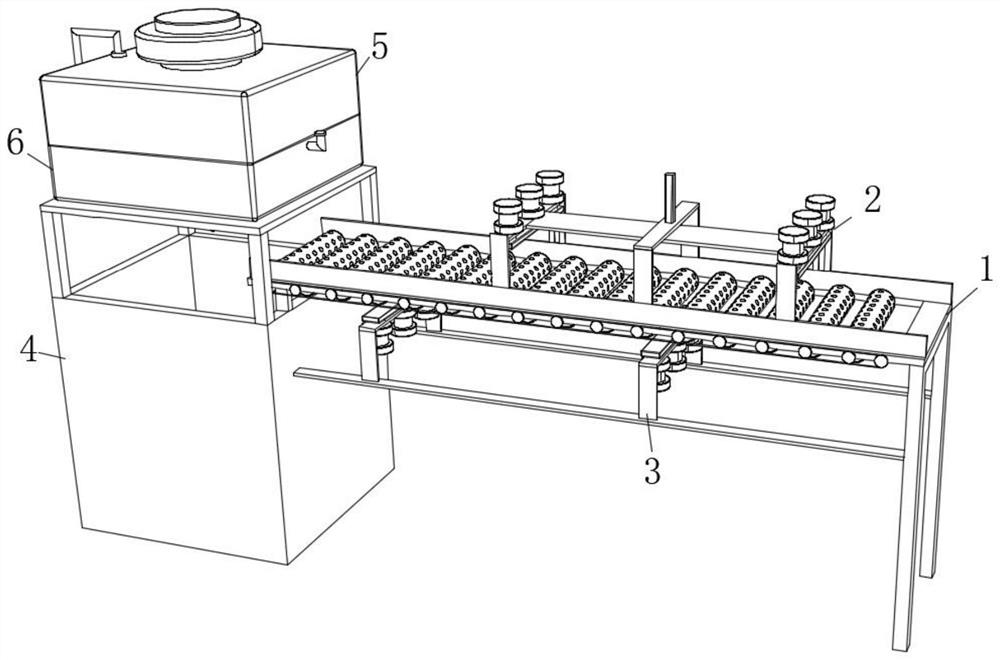

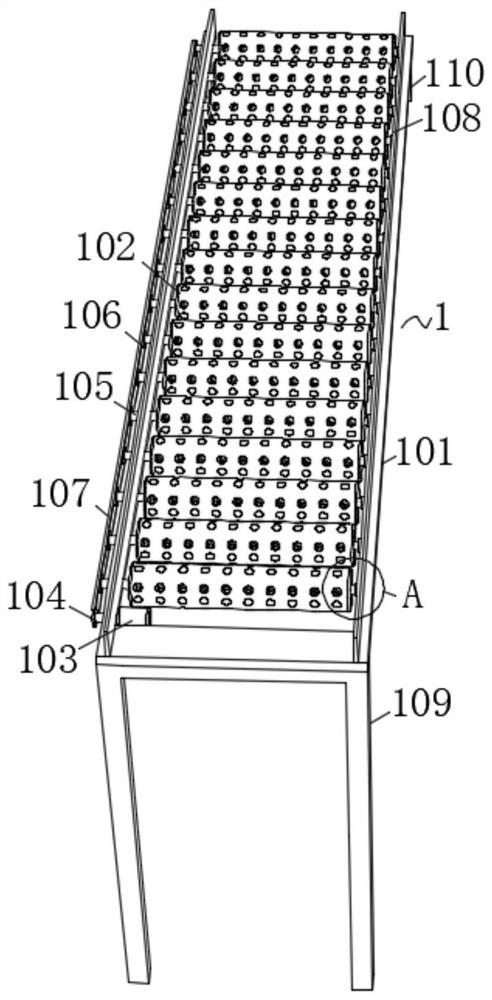

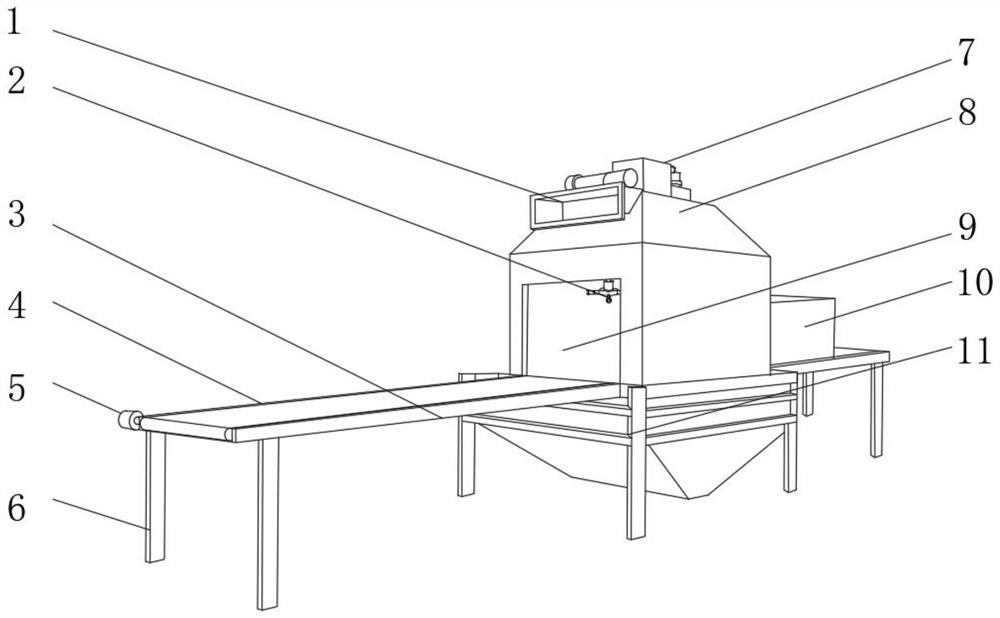

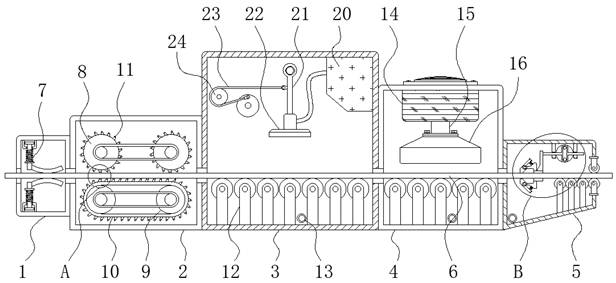

Rapid cooling device for aluminum profiles

InactiveCN111945085ARapid ventilation and heat dissipationFast and even heat dissipationEngineeringSpray cooling

The invention discloses a rapid cooling device for aluminum profiles, and relates to the technical field of aluminum profile production. The rapid cooling device comprises a conveying mechanism, wherein an upper cooling mechanism is arranged at the upper end of the conveying mechanism, a lower cooling mechanism is arranged on the bottom side of the conveying mechanism, a collecting mechanism is arranged at one end of the conveying mechanism, a spraying mechanism is arranged at the upper end of the collecting mechanism, a water return mechanism is arranged at the upper end of the spraying mechanism, and the conveying mechanism comprises a conveying frame and material conveying rollers arranged on the inner side of the conveying frame at intervals. According to the rapid cooling device, thealuminum profiles are conveyed through the material conveying rollers, cooling through holes are annularly distributed in the surfaces of the material conveying rollers at intervals, the contact areaof the aluminum profiles and the material conveying rollers is reduced, rapid ventilation and heat dissipation can be promoted when the aluminum profiles are conveyed, and ventilation and pre-coolingtreatment is conducted on the two faces of the conveyed aluminum profiles correspondingly; and water is sprayed out through a nozzle to conduct spraying cooling treatment on the aluminum profiles in acollecting box, so that the aluminum profiles can be rapidly and evenly cooled, and the treatment efficiency of aluminum profile cooling is improved.

Owner:马鞍山思哲知识产权服务有限公司

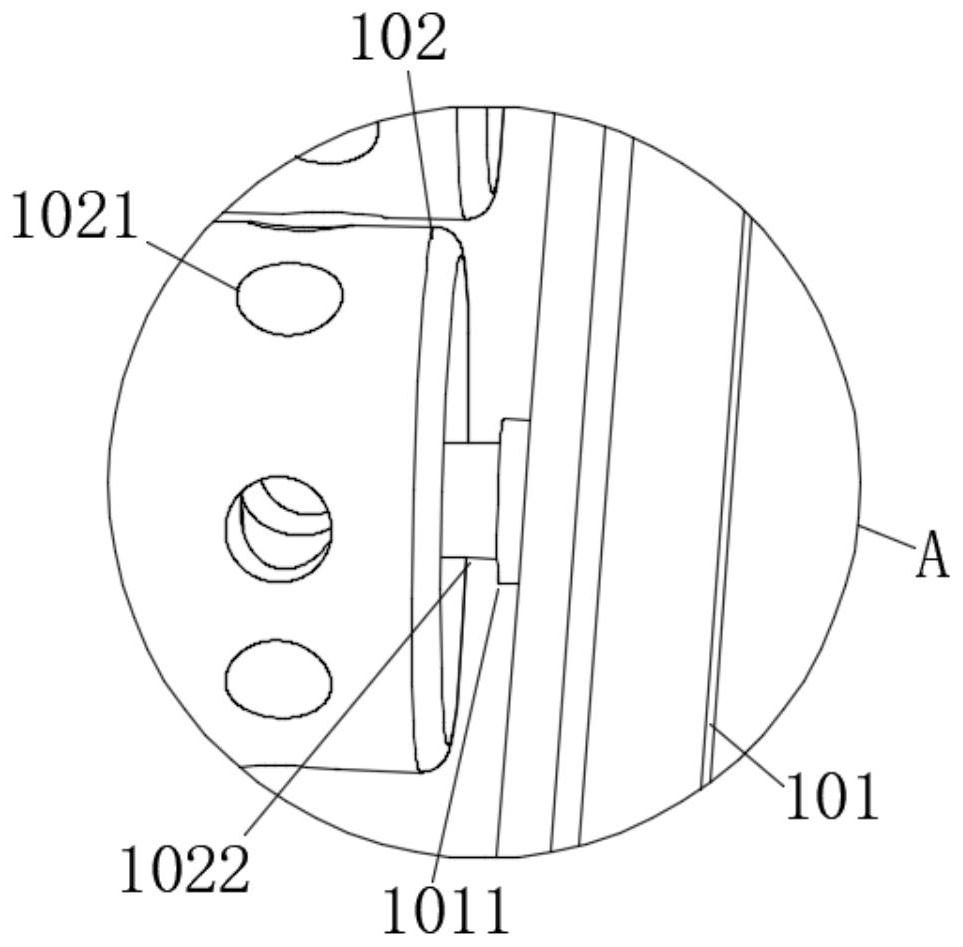

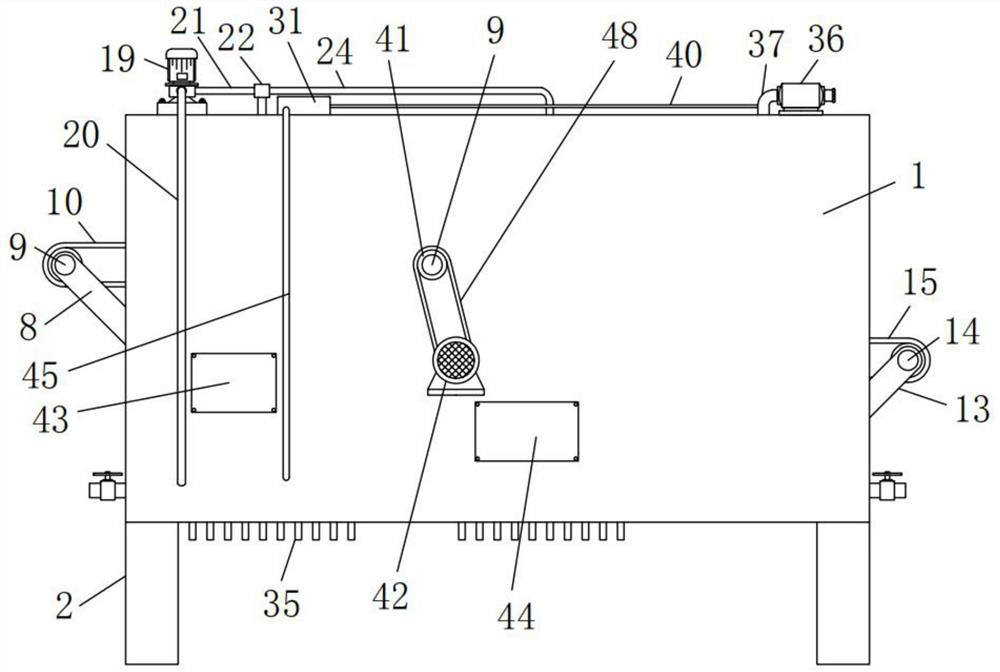

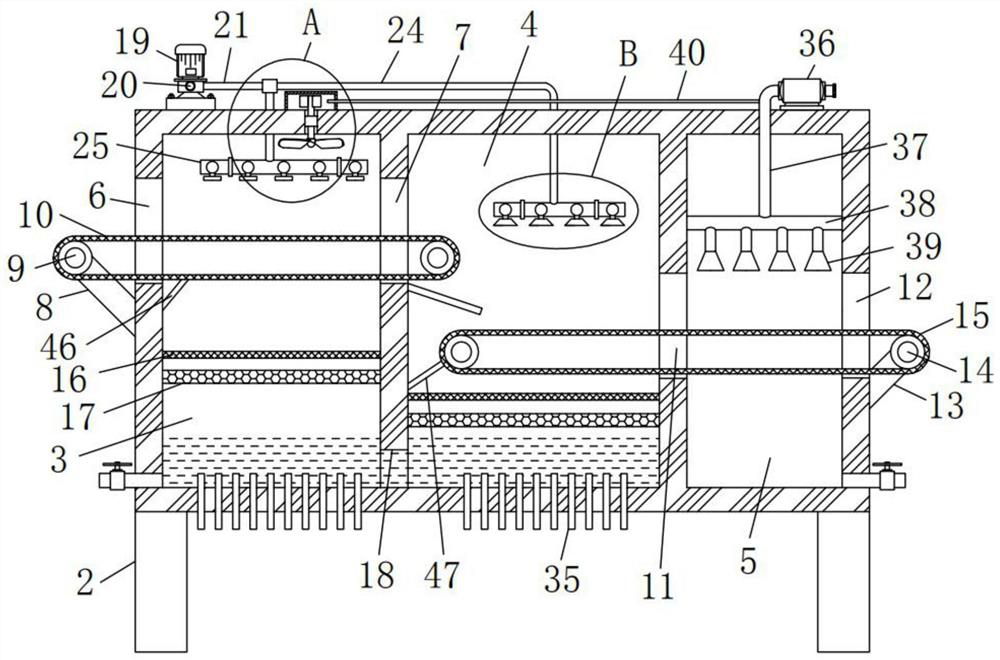

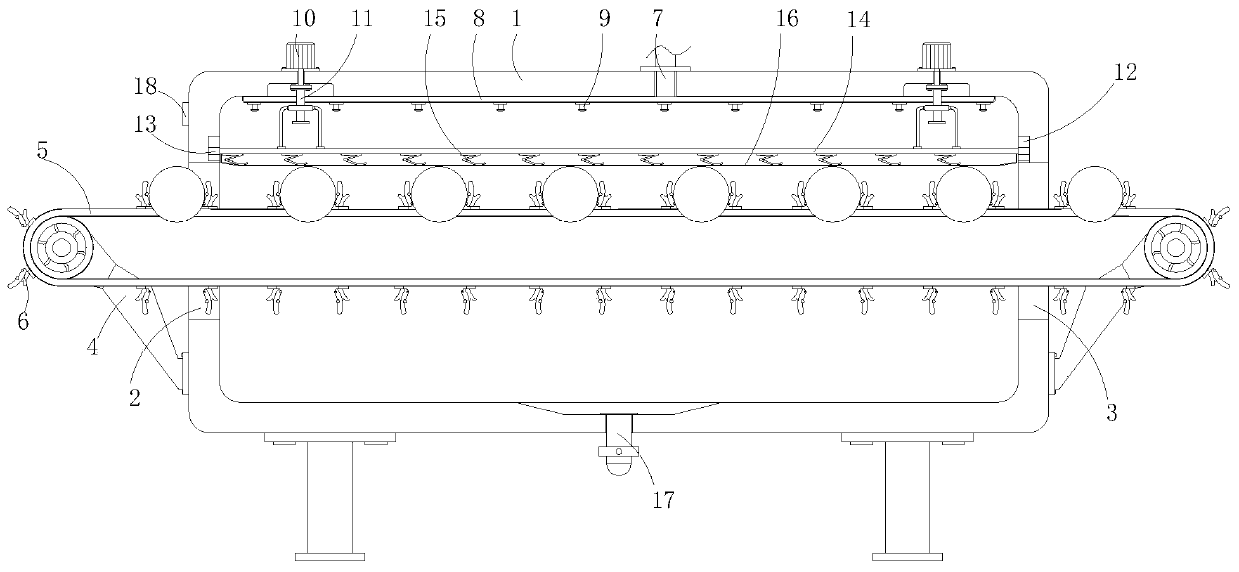

Cooling equipment for special type copper rod smelting forming

ActiveCN109518105AChange contactReduce contact surfaceFurnace typesHeat treatment furnacesFixed frameEngineering

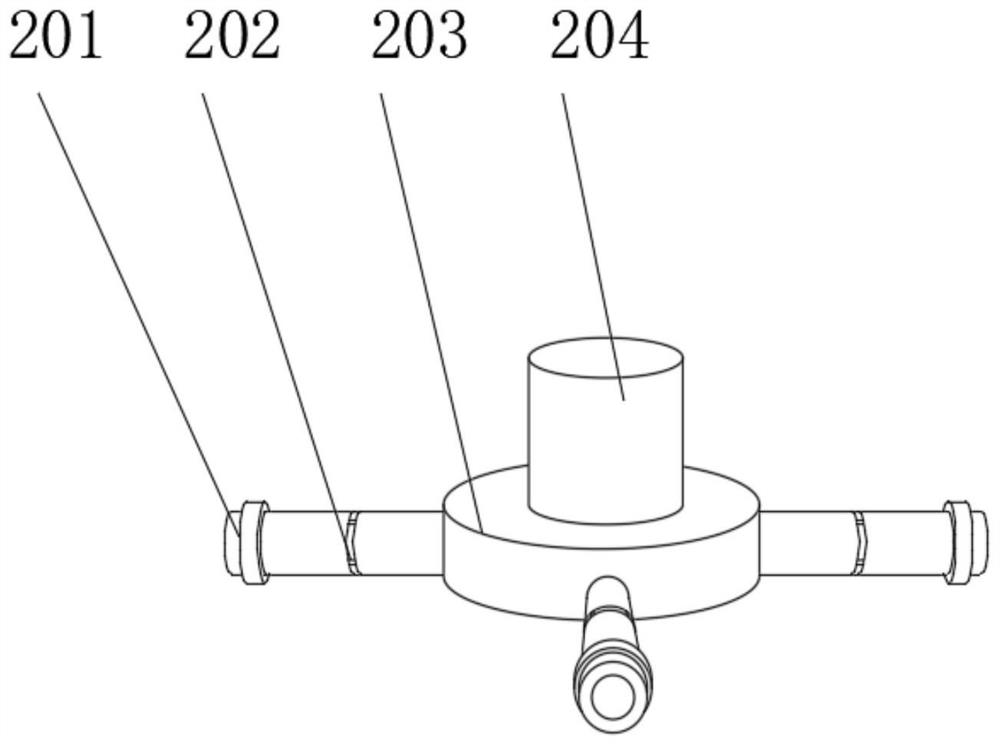

The invention relates to the technical field of machining of tube rod blanks of aluminum bronze, special brass and the like, and discloses cooling equipment for special type copper rod smelting forming. A guide inlet and a guide outlet are arranged in the left side and the right side of a machine body correspondingly; two fixing frames are fixedly installed at the guide inlet and the guide outleton the left side and the right side of the machine body through bolts correspondingly; two transmission mechanisms penetrate through the inner side of the machine body to be connected through the twofixing frames, and eighteen positioning mechanisms are installed on the two transmission mechanisms; and a water guide connector is installed at a water guide opening in the top of the machine body and penetrates through the top of the machine body to be connected with a transverse multi-way pipe. According to the cooling equipment for special type copper rod smelting forming, traditional surfacecontact or line contact is converted into point contact, the contact surfaces between the positioning mechanisms and copper rods are decreased, accordingly, the contact surface between cooling liquidand the side surfaces of the copper rods when the equipment conducts cooling is increased, and the problem that when the copper rods are subjected to cooling, metal structures on the sides of the copper rods are not synchronously cooled, and thus, the machining quality of the copper rods is influenced is solved.

Owner:贵溪骏达特种铜材有限公司

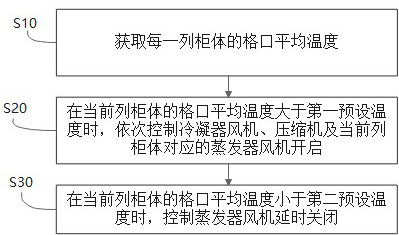

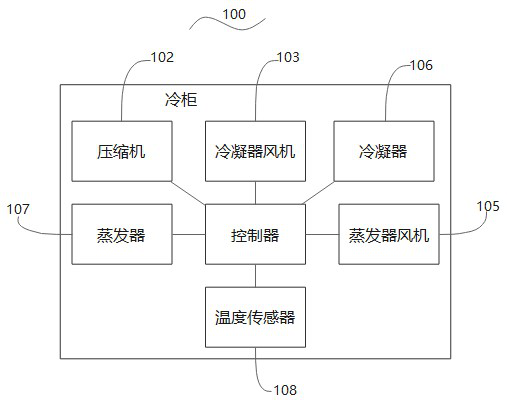

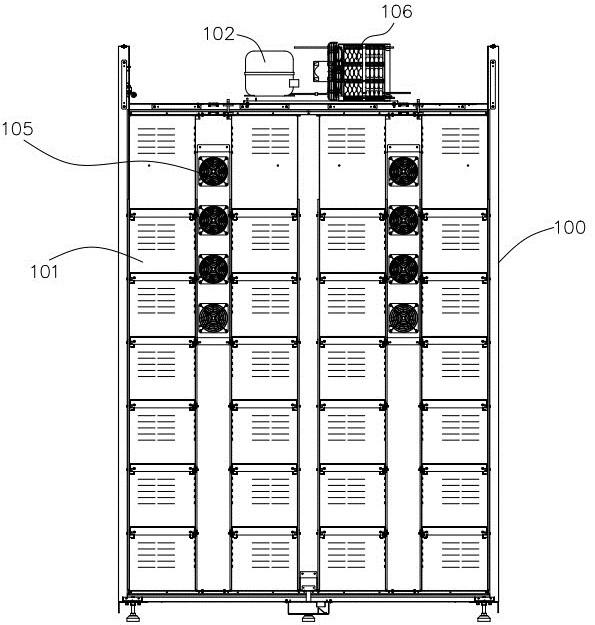

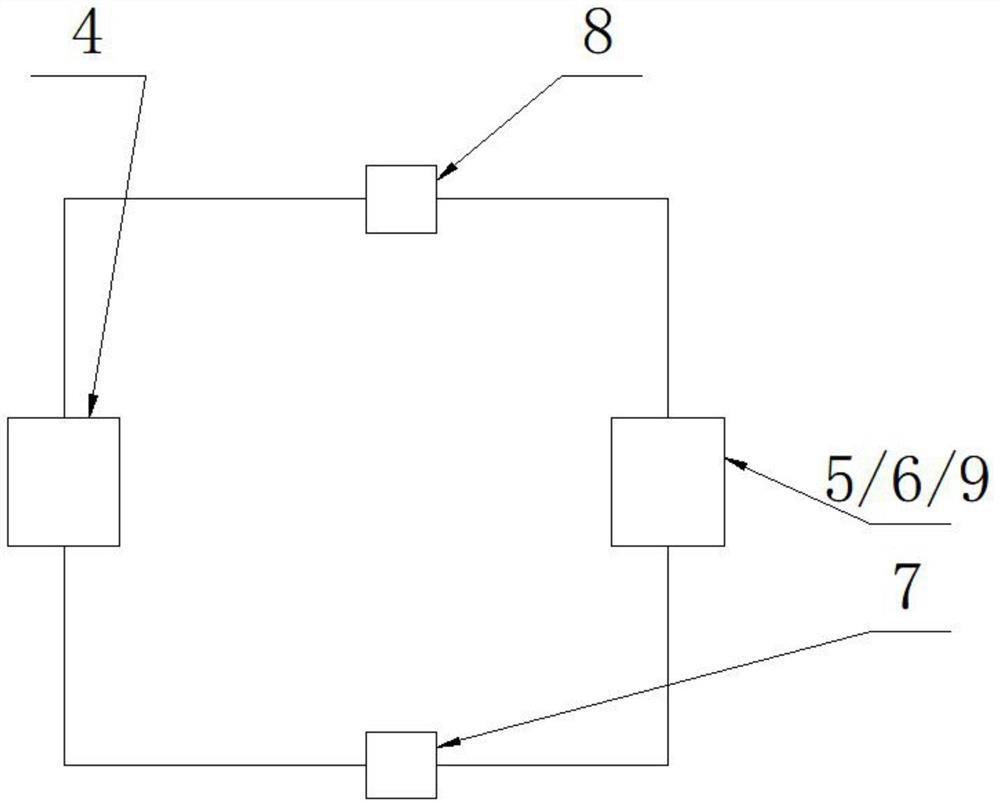

Refrigerator control method, refrigerator and computer readable storage medium

ActiveCN112304017AUniform cooling and coolingGood refrigeration and preservation effectDomestic refrigeratorsRefrigeration safety arrangementCool storageControl theory

The invention discloses a refrigerator control method, a refrigerator and a computer readable storage medium. The refrigerator comprises multiple columns of refrigerator bodies, a compressor and condenser fans, a set of evaporator fans are arranged between every two columns of refrigerator bodies, and the control method comprises the steps that the average temperature of cells of each column of refrigerator bodies is obtained; the condenser fans, the compressor and the evaporator fans corresponding to the current column of refrigerator bodies are sequentially controlled to be started when theaverage temperature of the cells of the current column of refrigerator bodies is higher than a first preset temperature; and when the average temperature of the cells of the current column of refrigerator bodies is lower than a second preset temperature, the evaporator fans are controlled to be turned off in a delayed manner, wherein the second preset temperature is lower than the first preset temperature. According to the control method of the refrigerator, each column of refrigerator bodies can be uniformly refrigerated and cooled, and the refrigerating and fresh-keeping effects are good.

Owner:SHENZHEN ZHILAI SCI & TECH

Disposable lunch box forming device and disposable lunch box processing energy-saving method

The invention discloses a disposable lunch box forming device. The device comprises a machine frame, a heating section and a forming section, and further comprises a preheating section, an air supplypiece, a hot air collecting piece and a draught fan, the heating section and the forming section are sequentially arranged on the machine frame, and the preheating section is mounted at the front endof the heating section. The air supply piece and the hot air collecting piece are arranged at the two sides of the upper portion of a blister mold of the forming section, the hot air collecting pieceis communicated to an air inlet of the draught fan through an air pipe, an air outlet of the draught fan is communicated to inlet air of the preheating section through an air pipe, and outlet air of the preheating section is communicated to the air supply piece through an air pipe. According to the disposable lunch box forming device and the disposable lunch box processing energy-saving method, hot air of the forming section can be recycled to preheat sheets entering the heating section, energy is saved, and the equipment operation cost is reduced.

Owner:涿州市郡腾塑料制品有限公司

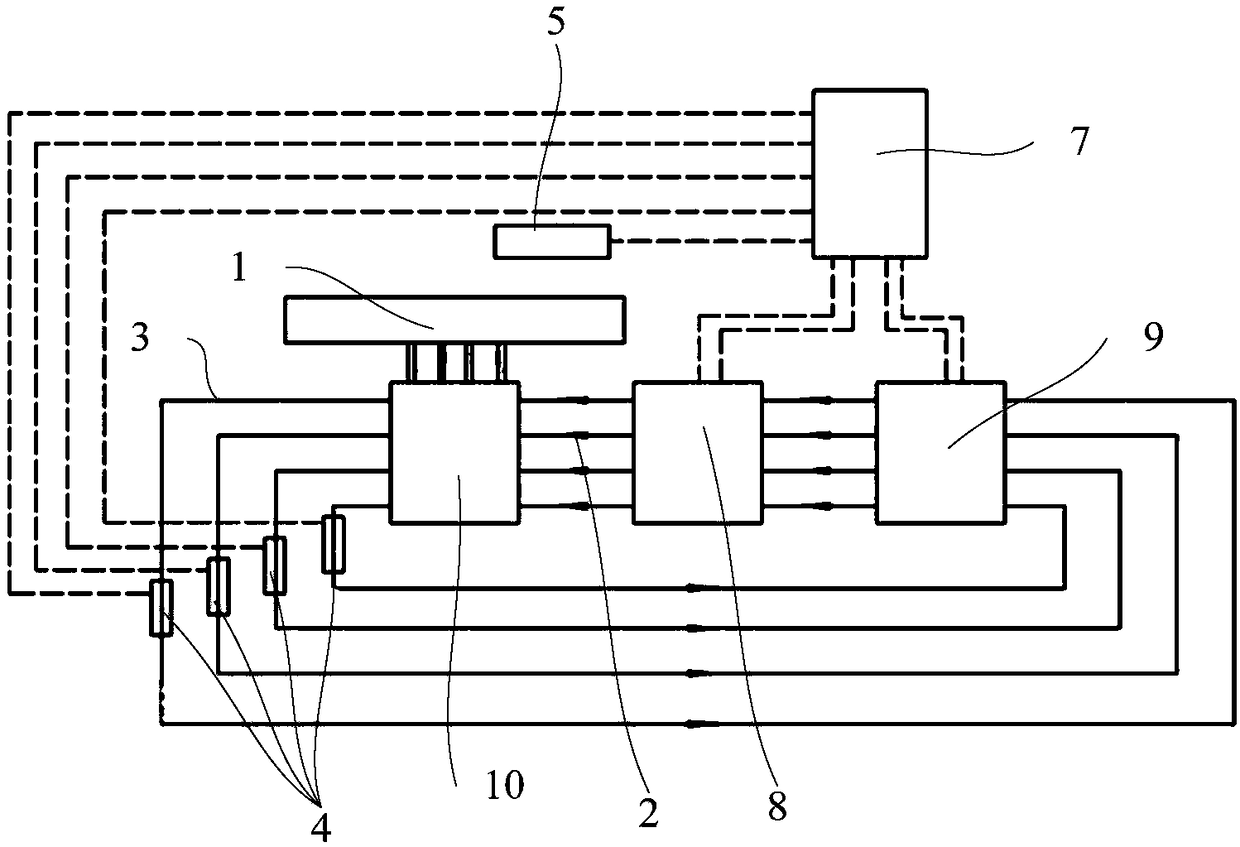

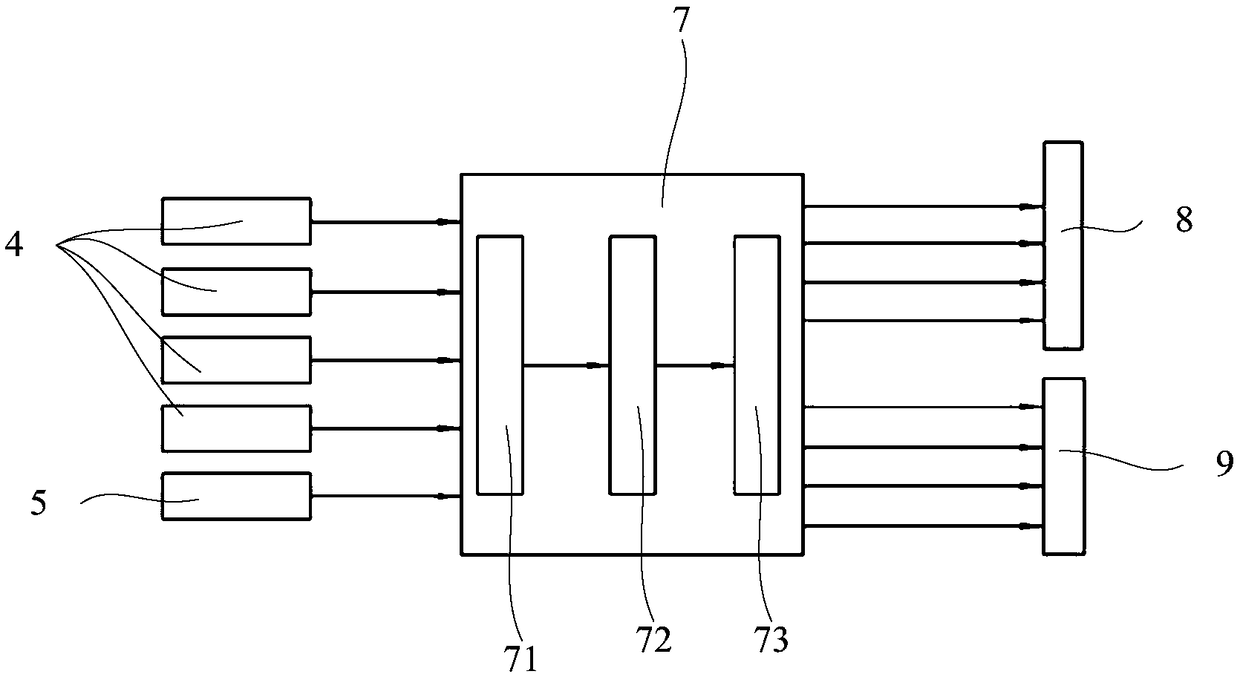

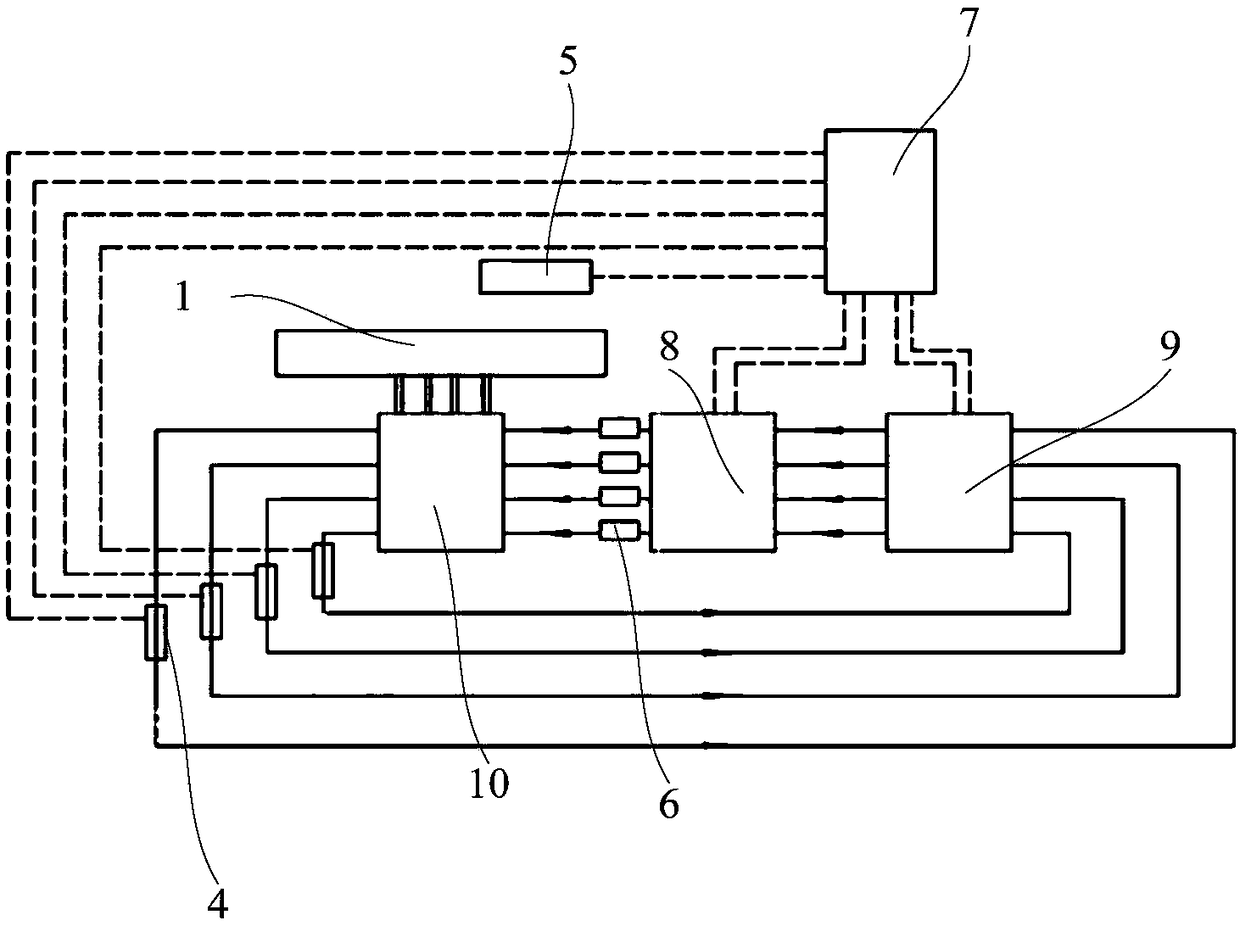

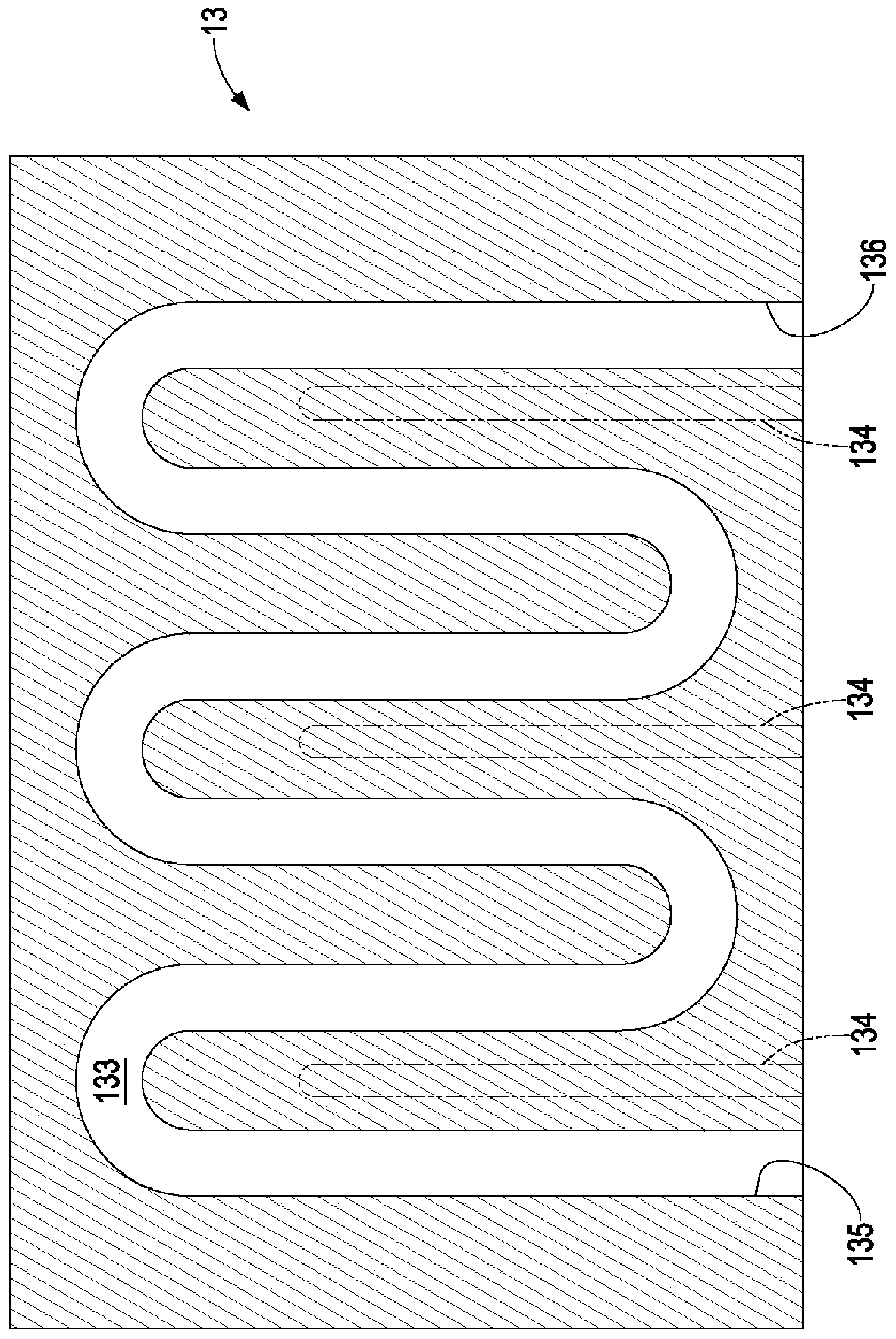

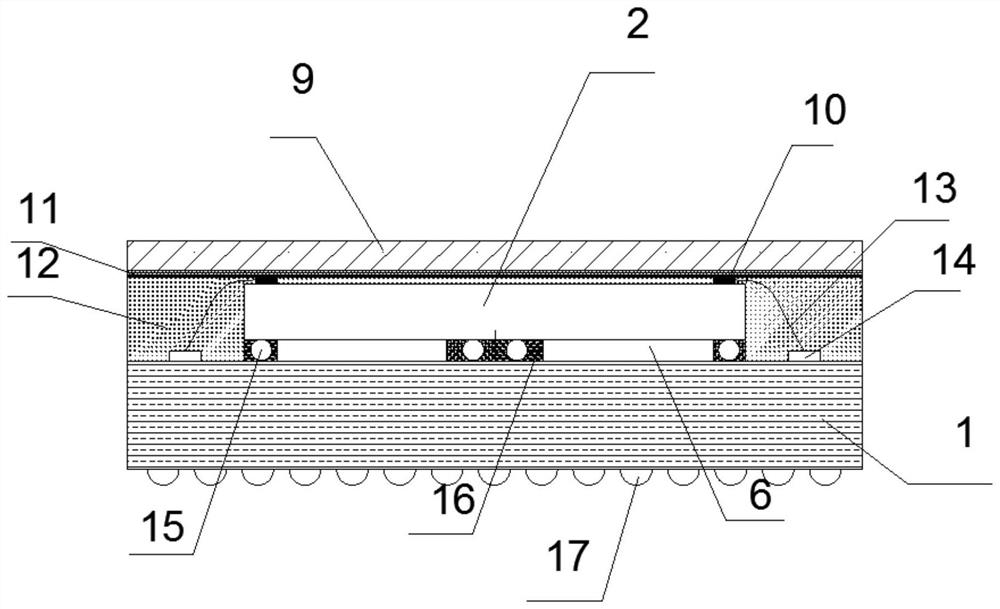

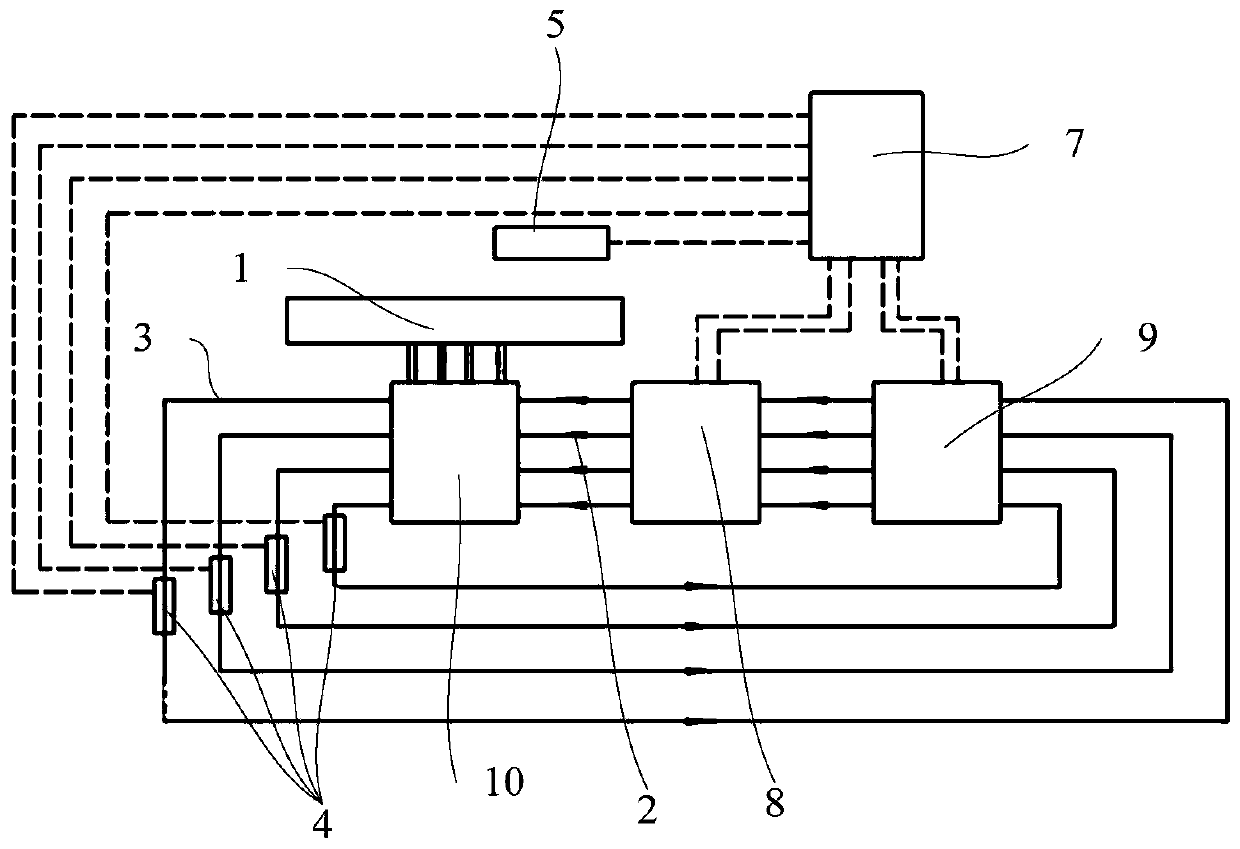

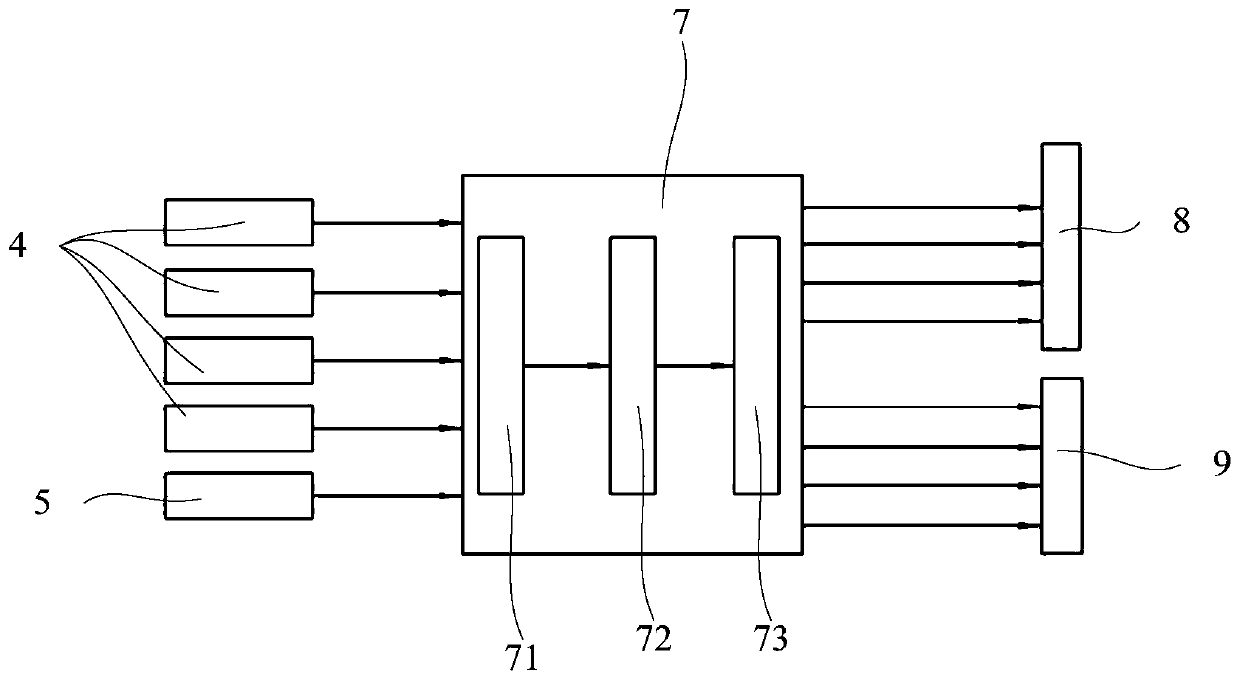

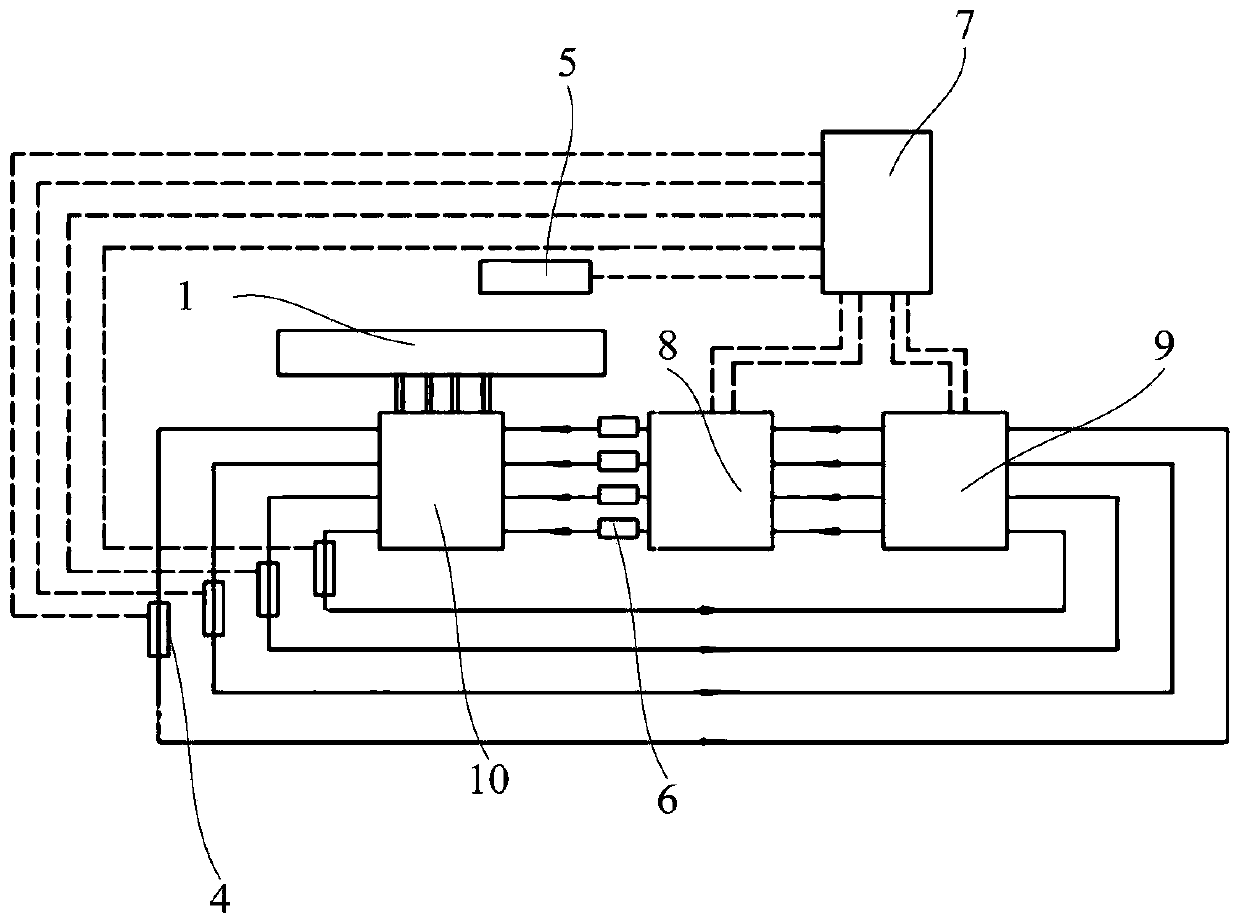

Temperature control system of polishing disk

ActiveCN109500740ACool evenlyGuaranteed polishing qualityGrinding feed controlGrinding/polishing safety devicesTemperature controlControl system

The invention relates to the technical field of CMP polishing disk temperature control, in particular to a temperature control system of a polishing disk. The temperature control system of the polishing disk comprises a polishing disk body, a circulating waterway, a temperature detecting device and an adjusting and controlling device; the circulating waterway comprises a plurality of water feedingpipelines and water return pipelines, the multiple water feeding pipelines separately correspond to different areas of the polishing disk body, and the water feeding pipelines correspond to the waterreturn pipelines one to one and communicate with the water return pipelines; the temperature detecting device detects the water return temperature of the water return pipelines and the surface temperature of the polishing disk body; and the adjusting and controlling device receives a temperature signal detected by the temperature detecting device, and controls the temperature and flow of coolingwater supplied to the polishing disk body by the water feeding pipelines. According to the temperature control system of the polishing disk, different areas are separately arranged on the polishing disk body, the independent water feeding pipelines and the water return pipelines are arranged in the areas, the temperature of the water return pipelines in the areas is monitored, the water feeding temperature and low of the water feeding pipelines are controlled, adaptive temperature adjustment and control of different areas is realized, so that the polishing disk body is cooled uniformly, and the polishing quality of a wafer is guaranteed.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

Preparation process of enhanced plastic pipeline material

The invention discloses a preparation process of an enhanced plastic pipeline material. The preparation process comprises the following steps that S1, materials are prepared; S2, material mixing is conducted, S3, melting is conducted, specifically, a blended material is molten by using a plastic extruder, and the molten material is output outwards; S4, extruding is conducted, specifically, the molten material is extruded and formed, and a formed pipe blank is output; S5, setting is conducted, specifically, the diameter of the extruded pipe blank is fixed; and S6, cooling is conducted, specifically, the formed product is cooled through a pipe forming cooling spraying device. According to the preparation process, polyvinyl chloride is adopted as a pipe base material, the base material is subjected to toughening and enhancing treatment through reinforcing filler, so that the obtained pipe has excellent mechanical property and corrosion resistance, meanwhile, the specially-made pipe forming cooling spraying device is adopted for cooling the formed pipe, so that the pipe can be uniformly cooled, the quality of a plastic pipeline is guaranteed, the recycling purpose of a water resourcecan be further achieved, and the process is simple and feasible, and has a wide application range.

Owner:安徽超星新材料科技有限公司

Cooling device for automobile parts

InactiveCN112629094AReduce wasteSpeed up the flowDomestic cooling apparatusTreatment involving filtrationWater resourcesCooling energy

The invention discloses a cooling device for automobile parts. The cooling device for the automobile parts comprises a box body, four supporting columns are fixedly installed at the bottom of the box body, every two of the four supporting columns are symmetrically arranged, a first-stage cooling cavity, a second-stage cooling cavity and a drying cavity are formed in the box body, and a feeding port and a first conveying port are formed in the inner walls of the two sides of the first-stage cooling cavity correspondingly. The cooling device for the automobile parts is reasonable in design and good in practicability, the automobile parts can be effectively cooled through two-times cooling, the automobile parts are cooled evenly, the phenomenon that the automobile parts deform or even crack due to the fact that the speed is too high when the automobile parts are cooled can be avoided, the surfaces of the automobile parts can be effectively cleaned, water can be recycled after being filtered and purified, waste of water resources is greatly reduced, the energy-saving effect is achieved, the surfaces of the automobile parts can be subjected to air drying treatment, and the surfaces of the automobile parts are kept dry.

Owner:汪利华

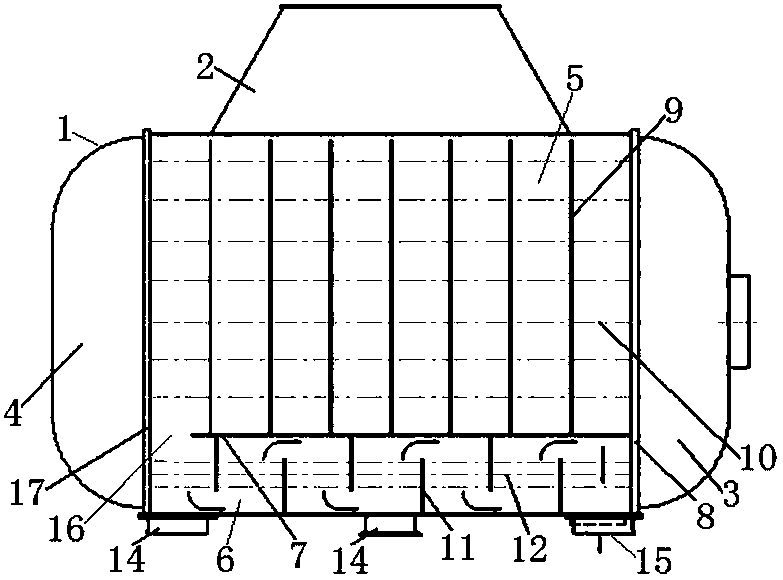

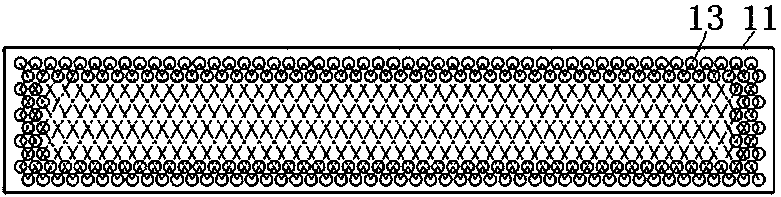

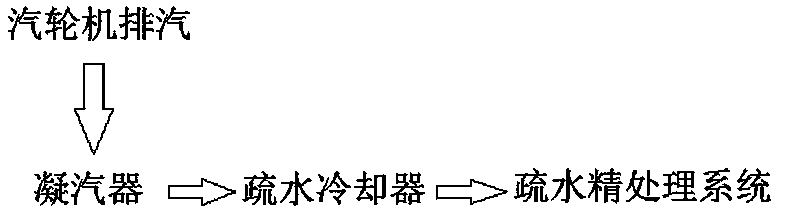

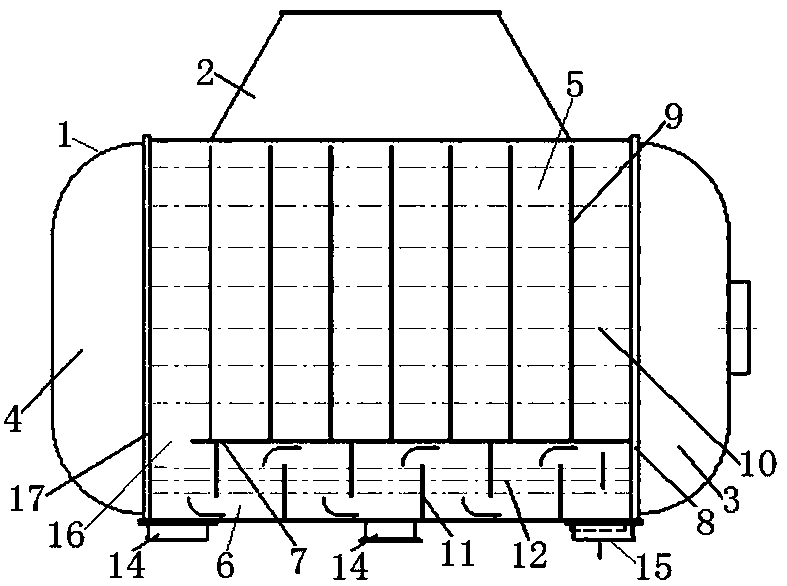

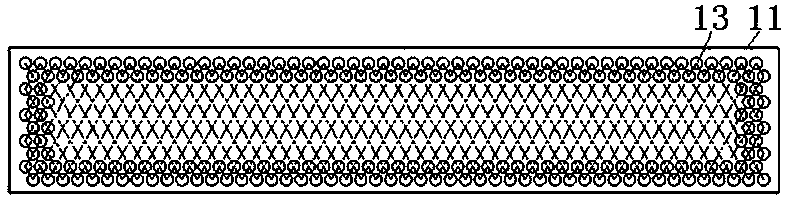

Turboset condenser

ActiveCN108253811AReduce operating costsReduce investmentSteam/vapor condensersHeat exchanger casingsWaste management

The invention discloses a turboset condenser. The turboset condenser comprises a shell; a front water chamber, a heat exchange chamber and a back water chamber are arranged in the shell; the heat exchange chamber is divided into a condensation area at the upper part and a cooling area at the lower part by a partition separation plate in the up-down direction; the condensation area and the coolingarea communicate through a drainage channel in the partition separation plate; the cooling area is provided with a dewatering outlet; a heat exchange structure is arranged in the cooling area; and multiple baffle plates for baffle control of a dewatering runner between the drainage channel in the partition separation plate and the dewatering outlet are arranged in the cooling area. The turboset condenser effectively, stably and reliably integrates the functions of condensation and cooling, can be applied to a turboset to reduce the place and equipment investment of the turboset, facilitates reduction of the operation cost of the turboset, and is excellent in economy.

Owner:DONGFANG TURBINE CO LTD

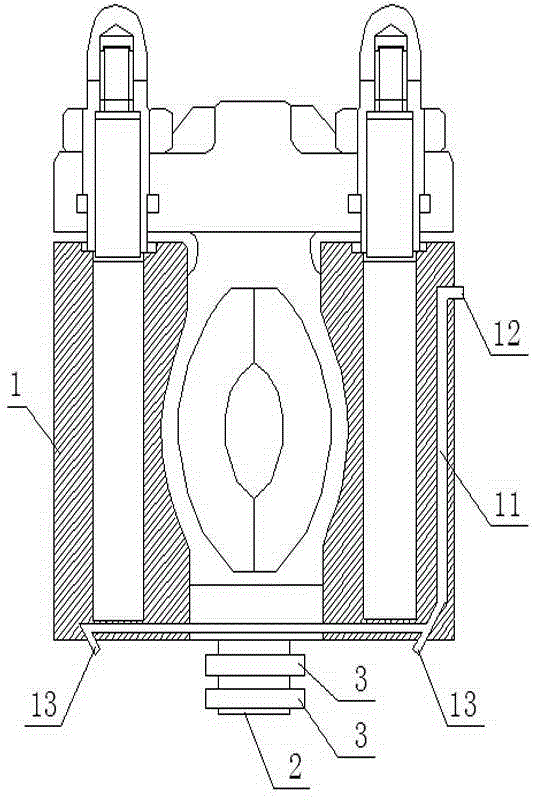

Die-casting mould for automobile filter shell body

The invention relates to the field of casting and provides a die-casting mould for an automobile filter shell body. The die-casting mould for the automobile filter shell body comprises an upper mould provided with a mold cavity, a lower mould provided with a mold core, a casting system communicating with the mold cavity and an air vent. The die-casting mould for the automobile filter shell body further comprises an annular cooling assembly and a point-mode cooling assembly which are arranged on the outer side of the side periphery of the mold cavity. A die-casting method is used for casting the automobile filter shell body, and the annular cooling assembly and the point-type cooling assembly are used for cooling, so that the temperature is uniform at the time of forming, crystals of a cast piece is fine, the cast piece is good in compactness, and the air hole detect is not prone to occurring.

Owner:宁波环亚机械制造有限公司

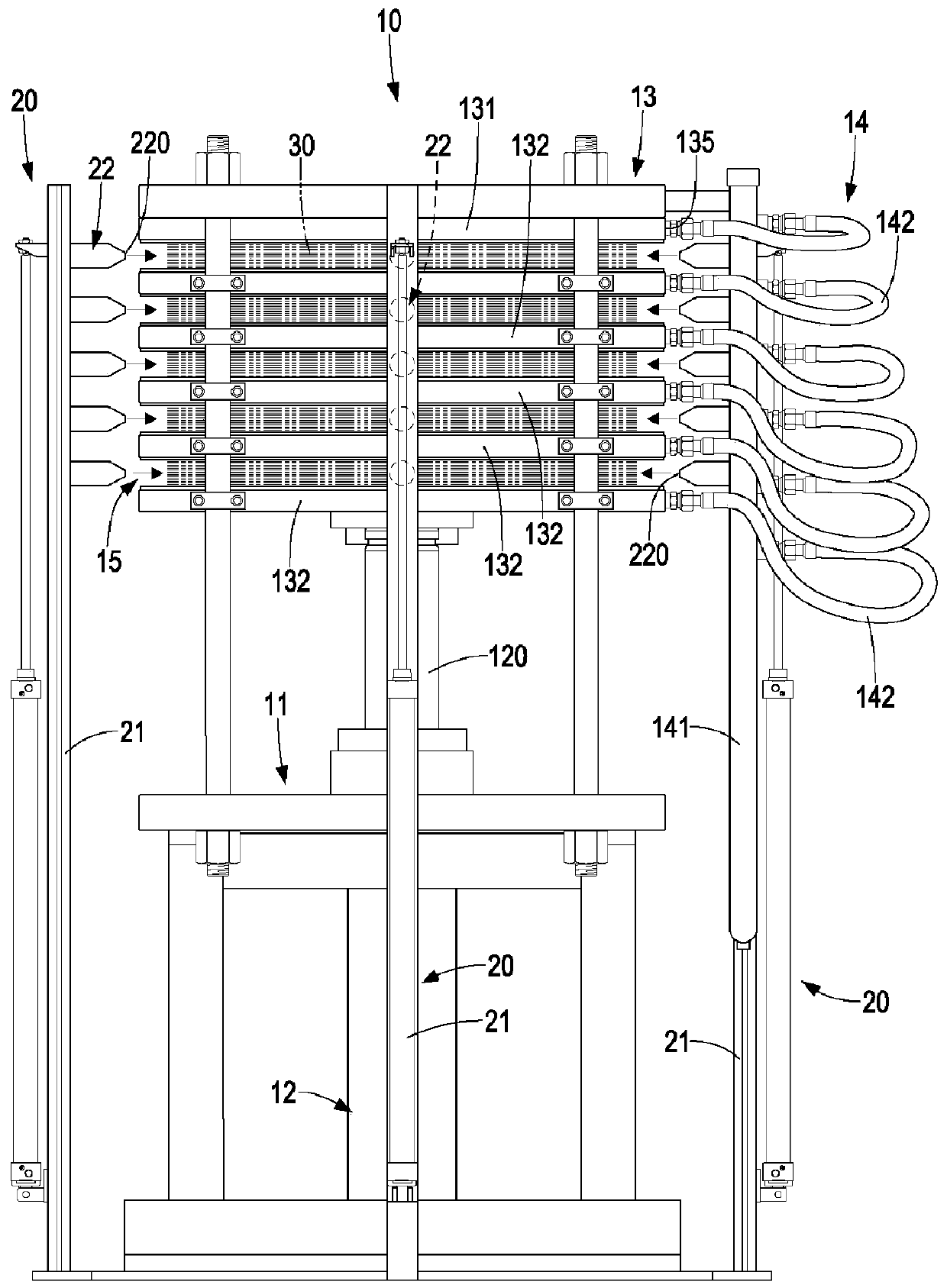

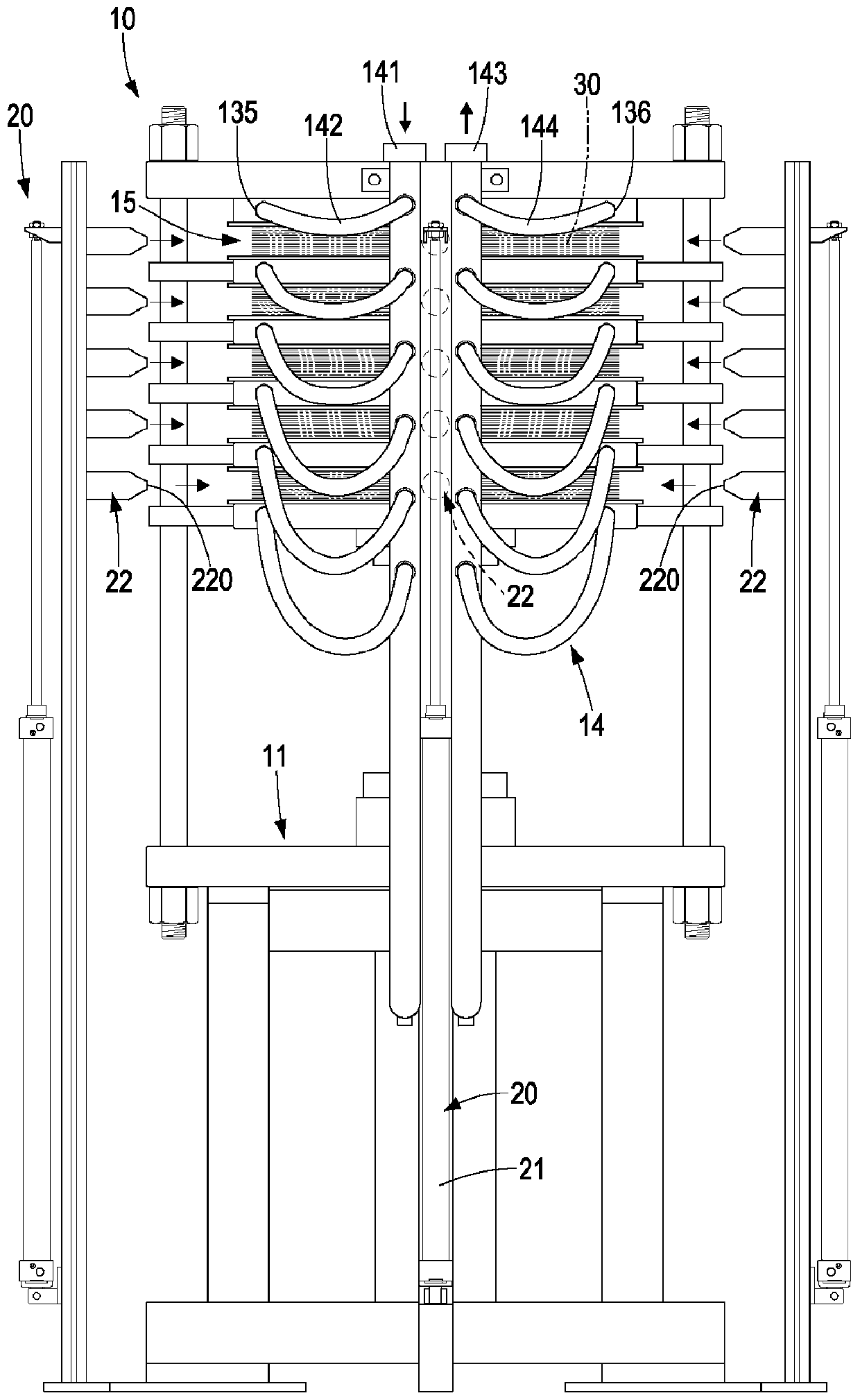

Cooling press with uniform cooling effect

ActiveCN106470529BUniform cooling and coolingImprove the excellent ratePrinted circuit manufactureCooling effectEngineering

The invention discloses a cooling laminating press with uniform cooling effect. The cooling laminating press comprises a body and a plurality of heating units, wherein the body comprises a rack body and a plurality of cooling pressing plates. The cooling pressing plates are jointed with the rack body at vertical intervals, at least one cooling pressing plate is fixedly connected with the rack body, and other cooling pressing plates can be raised and lowered down relative to the cooling pressing plate fixedly connected with the rack body. The cooling pressing plates arranged at vertical intervals form a receiving chamber, and the plurality of heating units surround outside of the circumferential surface of the rack body. Each heating unit is provided with a plurality of heating members, and each heating member is provided with a heat outlet facing the corresponding receiving chamber. Due to the heating members, the temperature of the peripheral areas of each printed circuit board is the same with the temperature of other central areas, so that integral uniform cooling contraction and cooling effect can be generated.

Owner:VIGOR MACHINERY

Refractory material product casting molding equipment

InactiveCN112428404AIncrease productivityWell mixedFeeding arrangmentsClay mixing apparatusRefractoryStructural engineering

The invention relates to the technical field of pouring equipment, and discloses refractory material product pouring forming equipment which comprises a cooling groove of an annular structure, whereina refrigerator is fixedly embedded in the side wall, close to the bottom, of the cooling groove, a matched annular plate is rotationally arranged in the cooling groove, and the annular plate is connected to the cooling groove through a positioning control mechanism; a plurality of annularly and evenly distributed grooves are formed in the upper surface of the annular plate, matched forming dies are arranged in the grooves, a plurality of annularly and evenly distributed heat conduction rods are fixedly connected to the lower surface of the annular plate, slide blocks are symmetrically and fixedly connected to the side wall of the annular plate, and annular grooves matched with the slide blocks are formed in the inner wall of the cooling groove; and the slide blocks are in sliding connection to the annular grooves. According to the refractory material product casting molding equipment, the performance of refractory castable can be fully guaranteed, and the mold cooling molding time canbe effectively shortened, so that the production efficiency of refractory material products is effectively improved.

Owner:马鞍山科润冶金材料有限公司

Alloy ingot casting mould with cooling device and ingot casting method thereof

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

Environment-friendly cooling device for aluminum profile machining

The invention relates to the technical field of aluminum profile production and machining, in particular to an environment-friendly cooling device for aluminum profile machining, the environment-friendly cooling device for aluminum profile machining comprises a conveying mechanism, a cooling box, an air cooling mechanism and a water cooling mechanism, the cooling box is provided with a cavity formed in the first direction, a feeding port and a discharging port, and the feeding port and the discharging port communicate with the cavity; the feeding port and the discharging port are oppositely arranged, the front side wall and the rear side wall of the cooling box are water curtain walls, and a plurality of mounting holes are formed in the top of the cooling box; the air cooling mechanism is arranged at the top of the cooling box and comprises a plurality of draught fans, and the multiple draught fans are arranged at the multiple mounting holes correspondingly; the water cooling mechanism is arranged in the cavity, the water cooling mechanism comprises an annular spraying pipe, a plurality of spraying heads arranged on the inner side of the annular spraying pipe in a communicating mode and a first water pump communicating with the annular spraying pipe, the environment-friendly cooling device for aluminum profile machining can evenly cool aluminum profiles, the quenching effect is improved, and the quality of the aluminum profiles is improved.

Owner:HUBEI SHIMEI TECH +1

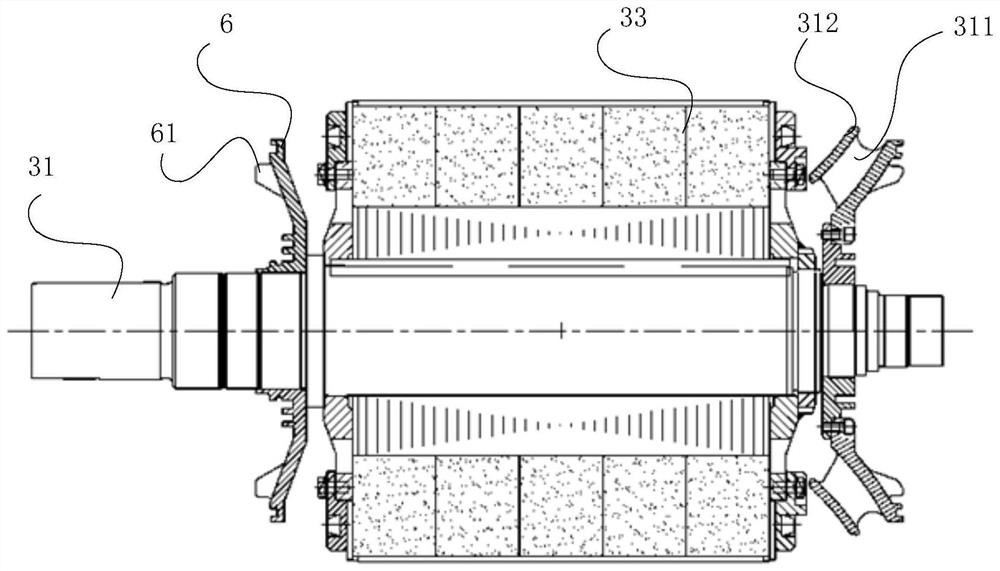

Air-water cooling high-power permanent magnet traction motor with hanging structure

InactiveCN112994355AUniform cooling and coolingBalanced heat distributionCooling/ventillation arrangementSupports/enclosures/casingsElectric machineMachine

An embodiment of the invention provides an air-water cooling high-power permanent magnet traction motor with a hanging structure. The air-water cooling high-power permanent magnet traction motor comprises a machine shell, a stator assembly and a rotor assembly. The machine shell surrounds to form an installation space for installing the stator assembly and the rotor assembly; an air cooling channel communicated with the installation space is formed in the machine shell; the rotor assembly comprises a rotating shaft; when the rotating shaft rotates, the blades on the rotating shaft are driven to rotate, and then air in the installation space is driven to flow into the air cooling channel; in the flowing process of the air, heat of a high-temperature area in the installation channel is absorbed, and heat is released to a low-temperature area, so that heat distribution of all the areas in the installation channel is balanced; and meanwhile, air exchanges heat with the machine shell when flowing in the air cooling channel, heat carried by the air is transmitted through the machine shell and dissipated to the outside atmosphere, and therefore uniform cooling of the interior of the high-power permanent magnet traction motor is achieved.

Owner:CRRC YONGJI ELECTRIC CO LTD

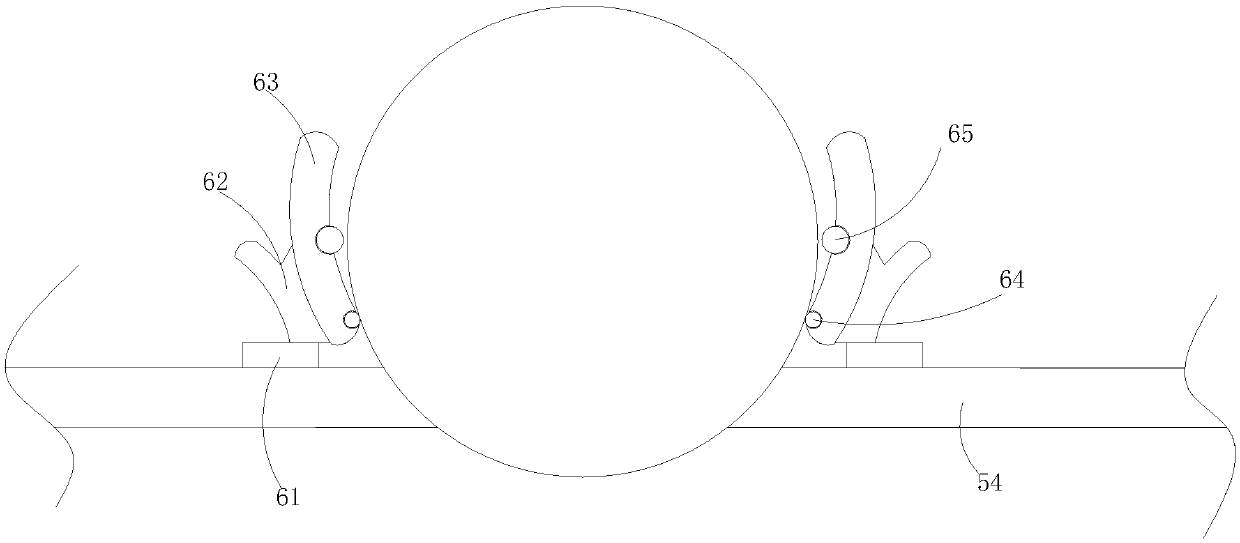

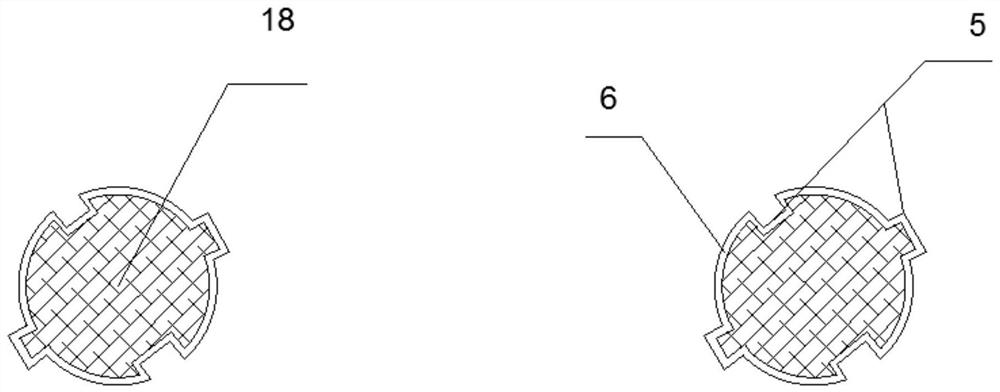

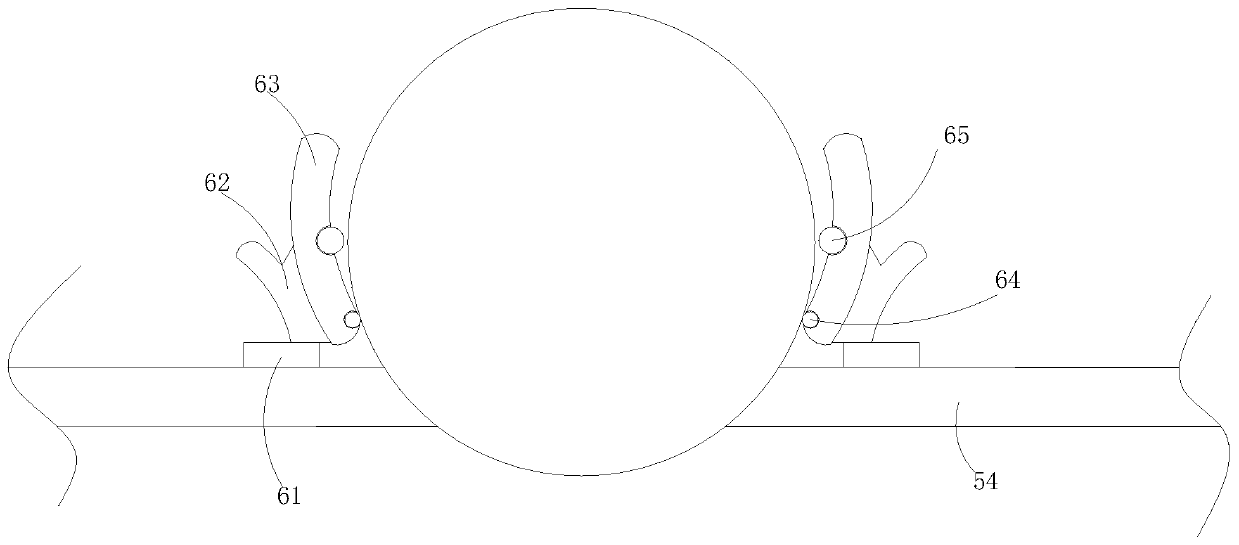

Guide and guard device

InactiveCN104399760ASimplify the assembly processUniform cooling and coolingGuiding/positioning/aligning arrangementsMarine engineeringStructural engineering

The invention discloses a guide and guard device. The guide and guard device comprises a guide and guard body; a rotary shaft is fixed in the center at the lower end of the guide and guard body; a bearing is arranged on the rotary shaft; the guide and guard body is provided with a water channel; one end of the water channel is provided with a water inlet; a water outlet which is formed in the other end is arranged at the lower end of the guide and guard body. According to the guide and guard device, the guide and guard body is provided with the water channel and accordingly the assembling process of simplifying guide and guard is achieved and maintenance is convenient; two water injection nozzles on a water pipe and the guide and guard body are communicated and accordingly uniform cooling and temperature reduction of a rolling wheel can be achieved and jamming due to the fact that the temperature of the rolling wheel is excessively high is avoided.

Owner:LIUZHOU RIP MACHINERY EQUIP

Cooling device applied to plastic production line and using method of cooling device

PendingCN112693098AWill not cause damagePlay the effect of atomization coolingDrying gas arrangementsHeating arrangementElectric machineCooling effect

The invention discloses a cooling device applied to a plastic production line and a using method of the cooling device. The cooling device comprises an air outlet, wherein a machine body is arranged on the outer surface of the lower end of the air outlet. In the plastic production and conveying process, plastic can pass through a conveying panel, a motor drives a conveying baffle on one side, a rotary spraying device at the upper end can prevent too much water from adhering to the plastic during spraying, an atomization cooling effect is achieved, water with a large area cannot adhere to the surfaces of plastic products, the next operation is facilitated, a condensation device on one side can achieve uniform cooling during cooling, plastic articles cannot be damaged due to non-uniform cooling, a drying device at the rear end can enable water mist to adhere to the surfaces of the plastic products cooled by atomized water during cooling, and the device can be used for effectively drying to ensure that the humid plastic products become dry quickly, is convenient to store and transport, ensures the high efficiency of quality, and is practical and convenient to operate.

Owner:宿松晨辉塑料制品有限公司

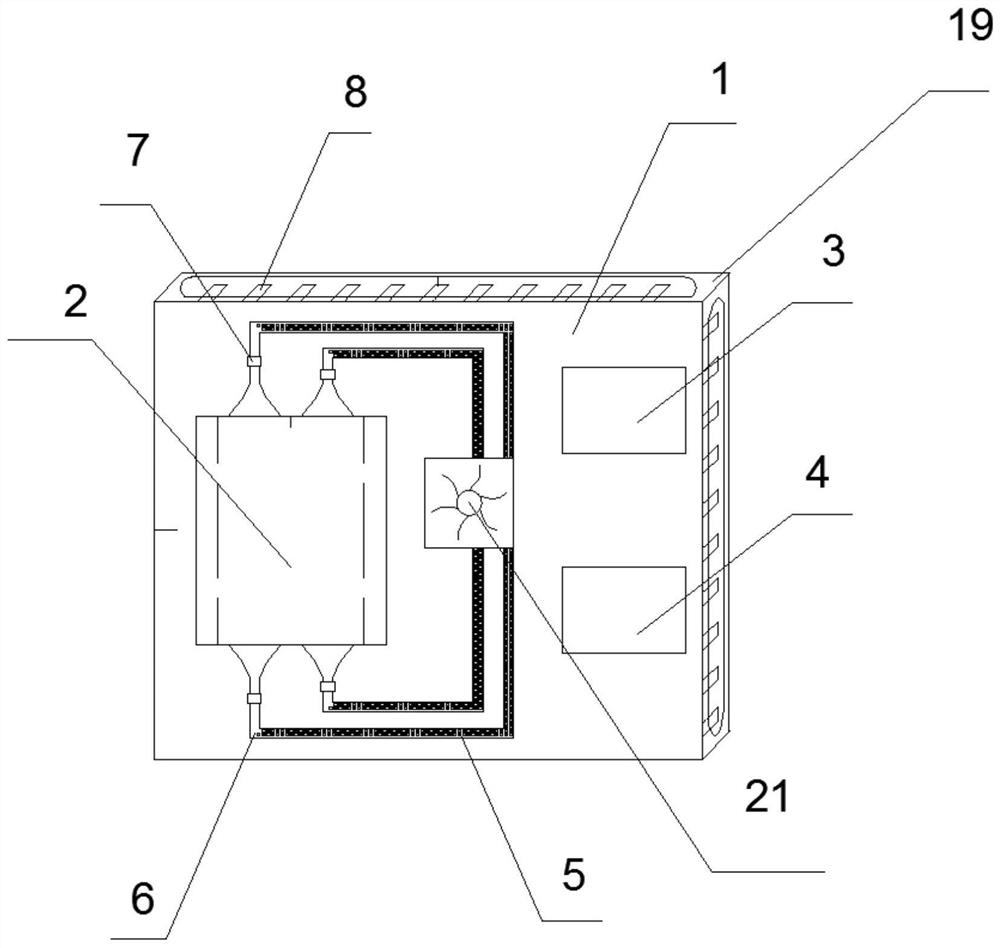

Structurally optimized integrated circuit package

PendingCN112234041AMeet the cooling effectImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention discloses an integrated circuit package with an optimized structure. The package comprises a substrate and is characterized in that three integrated circuit chips, namely a main integrated circuit chip, a first auxiliary integrated circuit chip and a second auxiliary integrated circuit chip, are packaged in the substrate; the two auxiliary integrated circuit chips are consistent in size and distributed on the right side of the substrate side by side, the area of the main integrated circuit chip is larger than that of the two auxiliary integrated circuit chips, two liquid coolingheat dissipation pipes are arranged between the lower portion of the main integrated circuit chip and the top of the substrate, and the two liquid cooling heat dissipation pipes are annularly distributed in total. The liquid cooling heat dissipation pipe is in a cylindrical pipe shape on the periphery of the main integrated circuit chip and is arranged above the substrate in a square surrounding mode, a pipeline, close to one side of the substrate, of the liquid cooling heat dissipation pipe gradually deforms from a cylinder to a flat rectangular state and penetrates through the lower side ofthe main integrated circuit chip, and the liquid cooling heat dissipation pipe has the advantages of being good in heat dissipation performance and high in packaging efficiency.

Owner:江苏盐芯微电子有限公司

Polishing disc temperature control system

ActiveCN109500740BUniform cooling and coolingAchieve coolingGrinding feed controlGrinding/polishing safety devicesTemperature controlControl system

The invention relates to the technical field of CMP polishing disk temperature control, in particular to a temperature control system of a polishing disk. The temperature control system of the polishing disk comprises a polishing disk body, a circulating waterway, a temperature detecting device and an adjusting and controlling device; the circulating waterway comprises a plurality of water feedingpipelines and water return pipelines, the multiple water feeding pipelines separately correspond to different areas of the polishing disk body, and the water feeding pipelines correspond to the waterreturn pipelines one to one and communicate with the water return pipelines; the temperature detecting device detects the water return temperature of the water return pipelines and the surface temperature of the polishing disk body; and the adjusting and controlling device receives a temperature signal detected by the temperature detecting device, and controls the temperature and flow of coolingwater supplied to the polishing disk body by the water feeding pipelines. According to the temperature control system of the polishing disk, different areas are separately arranged on the polishing disk body, the independent water feeding pipelines and the water return pipelines are arranged in the areas, the temperature of the water return pipelines in the areas is monitored, the water feeding temperature and low of the water feeding pipelines are controlled, adaptive temperature adjustment and control of different areas is realized, so that the polishing disk body is cooled uniformly, and the polishing quality of a wafer is guaranteed.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

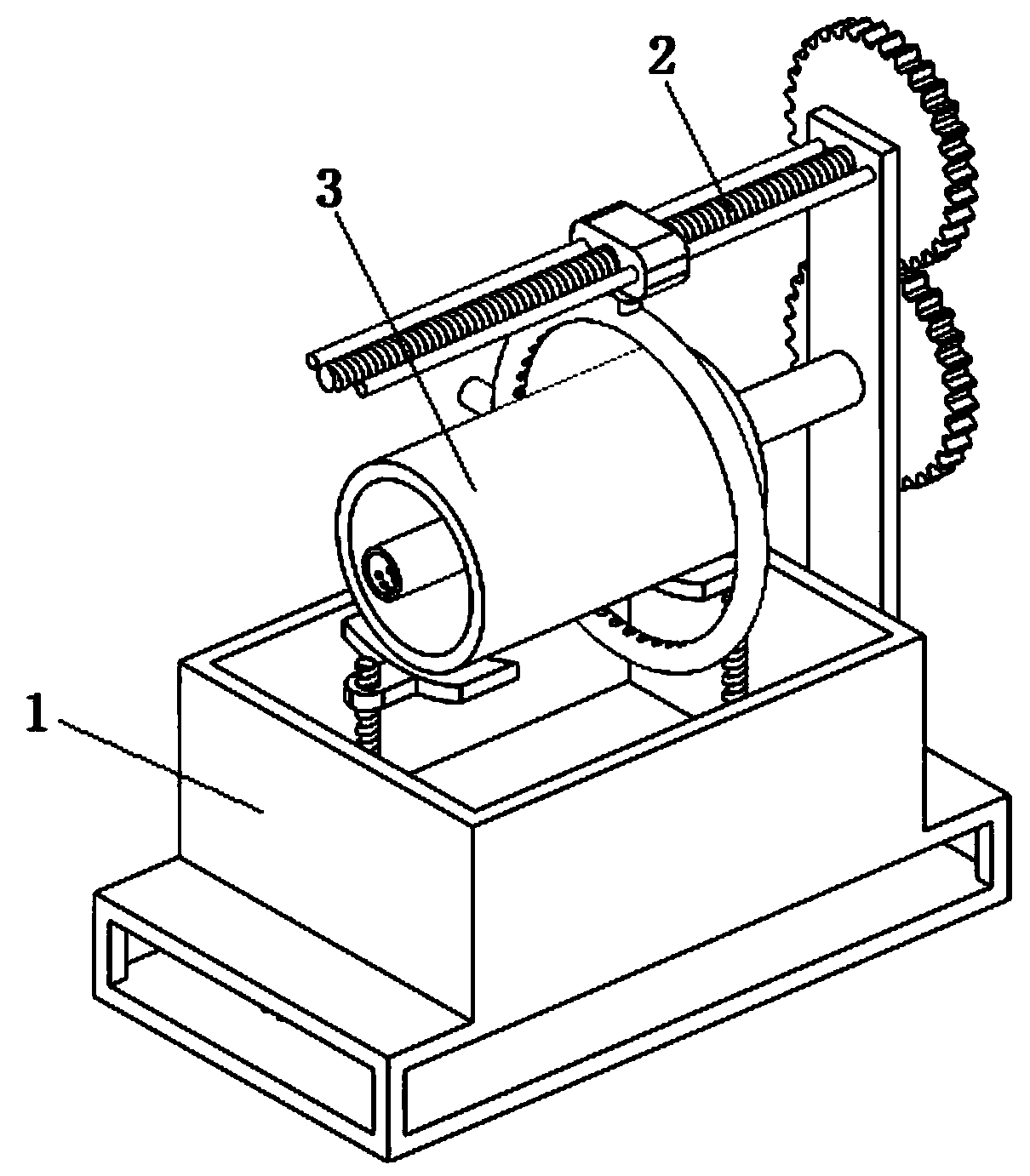

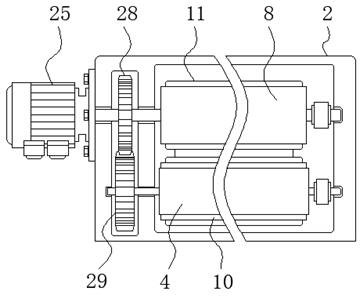

A heat treatment device for the production of machine tool rotary shafts

ActiveCN110983009BRapid cooling downImprove cooling effectFurnace typesHeat treatment furnacesElectric machineryEngineering

The invention discloses a heat treatment device for production of rotating shafts of a machine tool. The device comprises a quenching box and a liquid storage box, wherein the outer wall of the bottomof the quenching box is provided with a machine shell; the inner wall at the bottom of the machine shell is provided with a motor, and a fixing frame is arranged on the outer wall of one end of an output shaft of the motor; first electric push rods are arranged on the outer walls of the two sides of the fixing frame, clamping rings are arranged on the outer walls of one ends of the first electricpush rods, and rotating shaft bodies are clamped on the inner walls of one sides of the clamping rings; and a liquid outlet pipe is inserted into the outer wall of the top of the liquid storage box,and a corrugated pipe is inserted into the inner wall of one end of the liquid outlet pipe. According to the device, after the rotating shaft bodies are placed in the quenching box, lye can be sprayedto the surfaces of the rotating shaft bodies through a spray head on the outer wall of one side of a spray pipe so that the rotating shafts can be rapidly cooled, and meanwhile, people can adjust thedistance from the spray head to the rotating shaft bodies through stretching of a second electric push rod, so that the rotating shaft bodies are better cooled.

Owner:江苏伯能机床制造有限公司

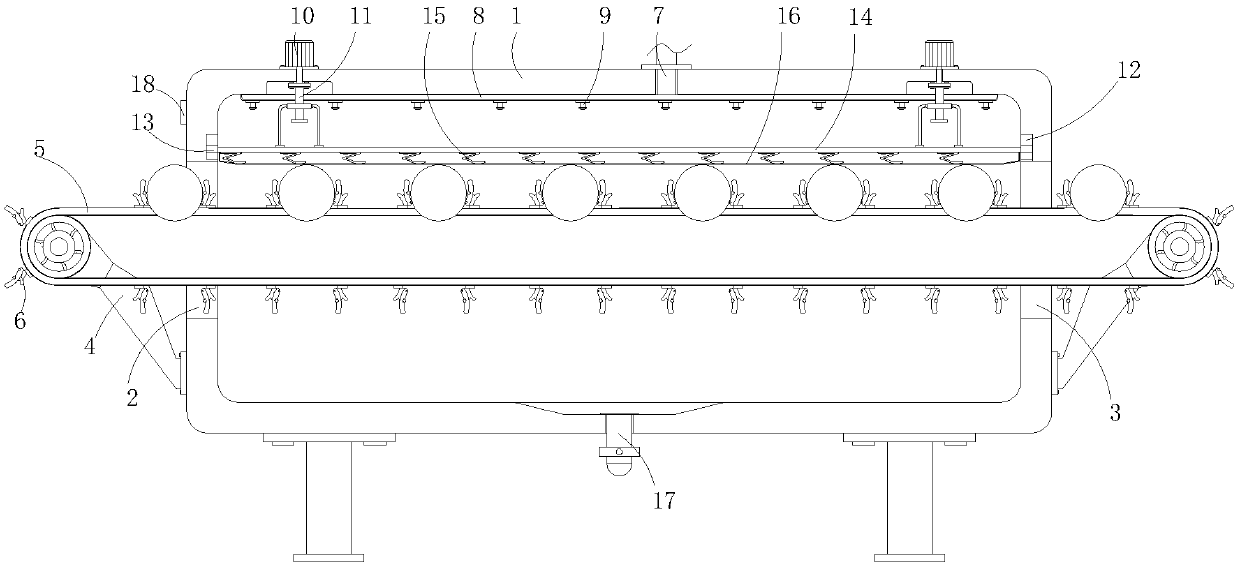

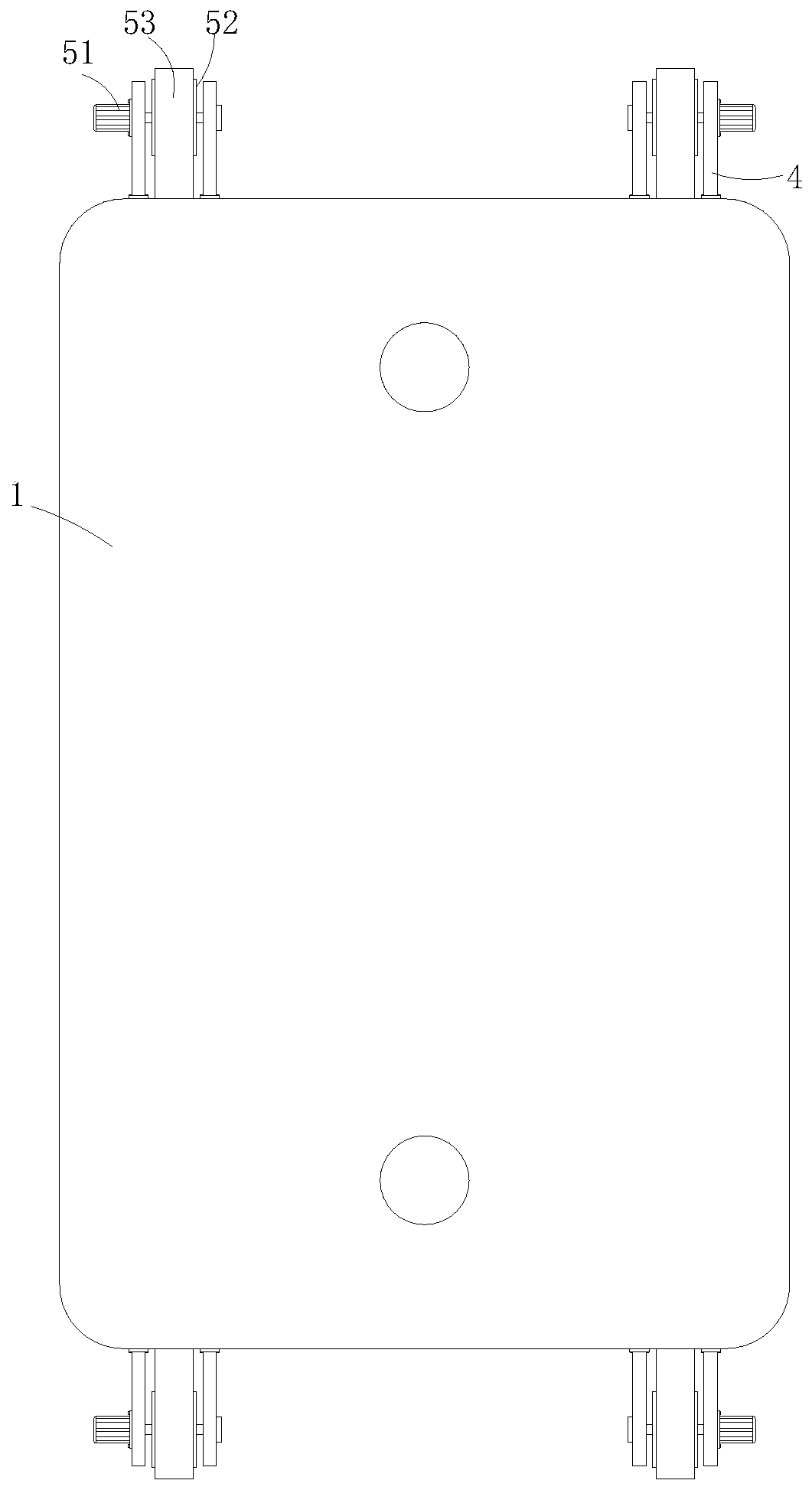

Cooling and conveying device used for aluminum profile production and capable of avoiding uneven cooling

InactiveCN113941616AUniform cooling and coolingEasy automatic removalConveyorsDrive wheelEngineering

Owner:马丽彩

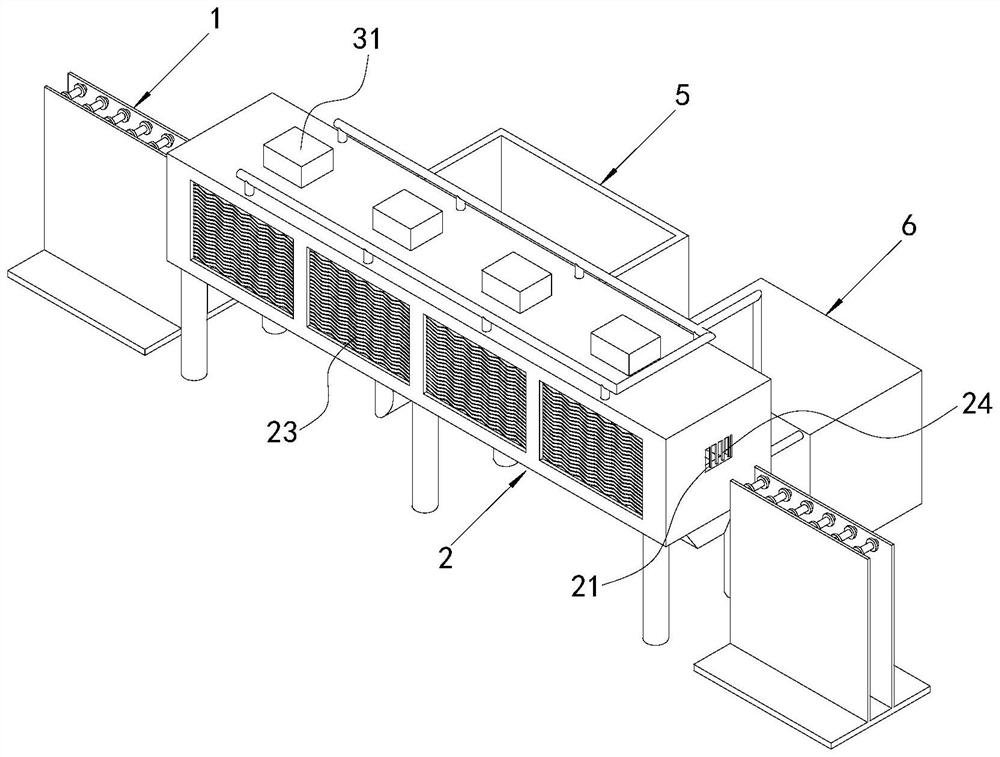

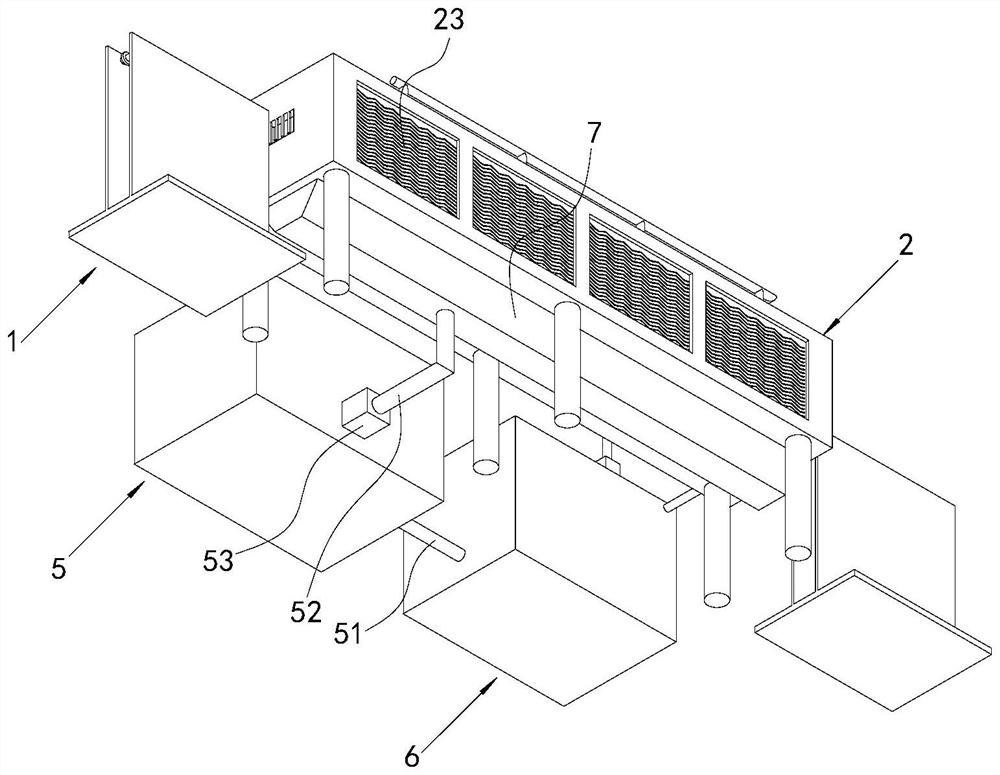

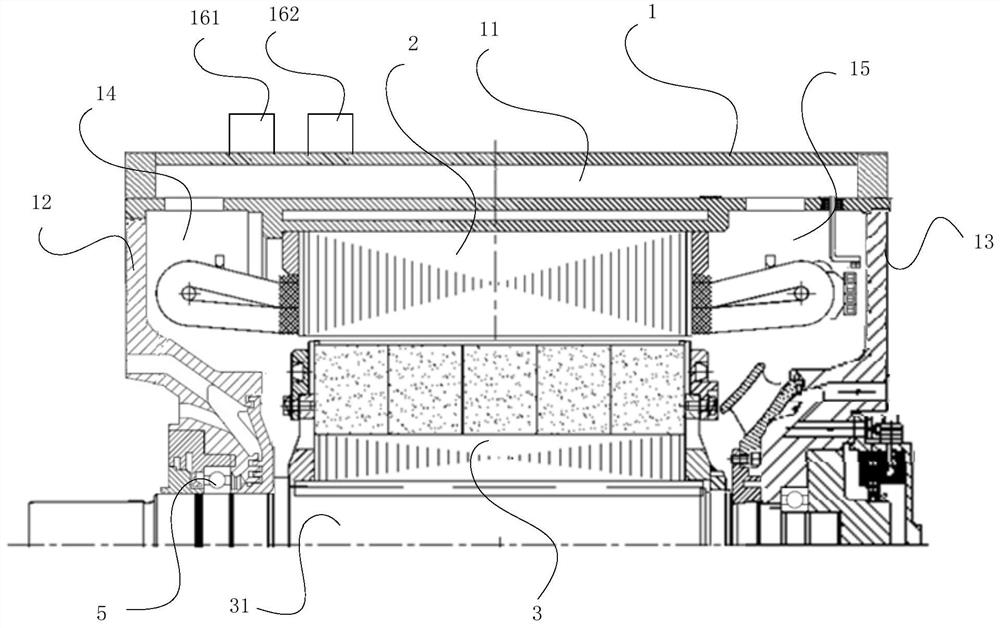

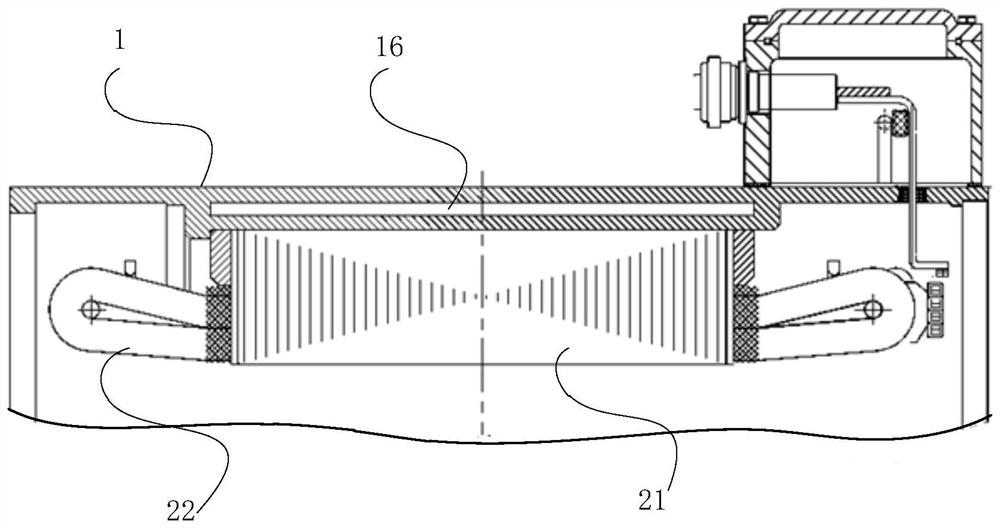

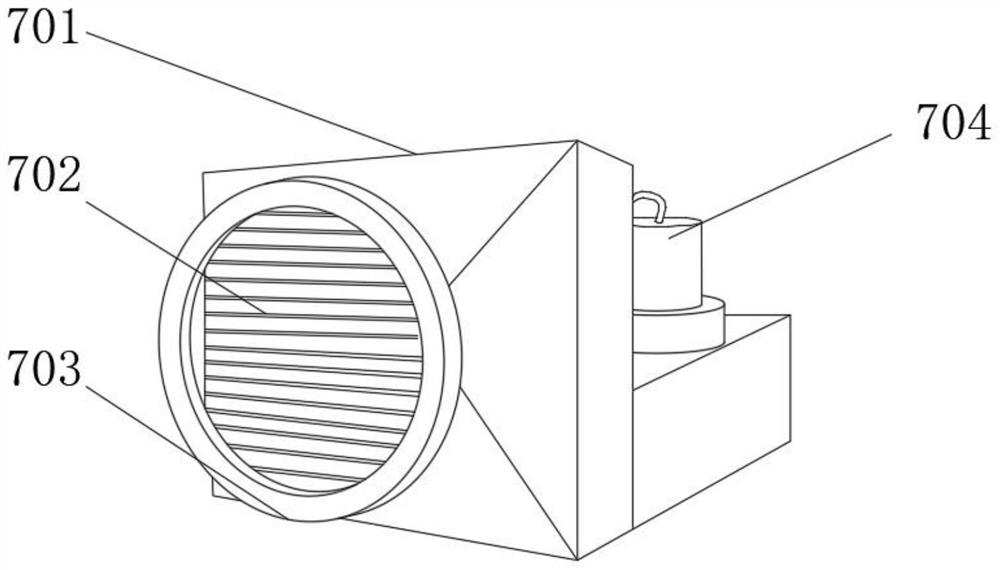

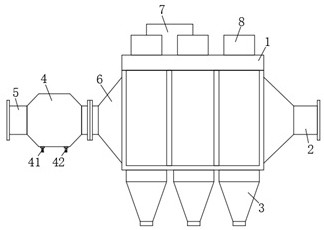

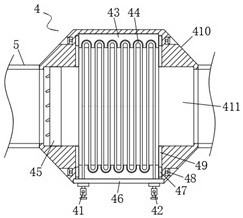

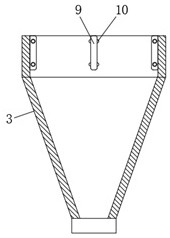

Low-low-temperature electric dust remover

ActiveCN112452544AEvenly distributedUniform cooling and coolingCombustion technology mitigationElectrostatic separation detailsThermodynamicsFlue gas

The invention discloses a low-low-temperature electric dust remover, and relates to the technical field of low-low-temperature electric dust removers. The dust remover comprises a machine body; an electric dust removal device which is mounted on the machine body and is used for carrying out electric dust removal on the flue gas conveyed into the machine body; a controller which is mounted at the top end of the machine body, wherein the controller is used for controlling the electric dust remover to work; a heat exchange device which is used for cooling the flue gas and comprises a heat exchange assembly, an air distribution mechanism, a box body and an inserting assembly for installing the heat exchange assembly and the box body. According to the invention, the air distribution mechanism is arranged, and the inclination angles of the five blade plates are adjusted, so that the flue gas can uniformly flow through the heat exchange assembly in the heat exchange device, the uniform distribution of the flue gas is realized, the uniform cooling of the flue gas is facilitated, and the dust removal effect of the flue gas is effectively improved.

Owner:JIANGSU LVDOU ENVIRONMENTAL ENG CO LTD

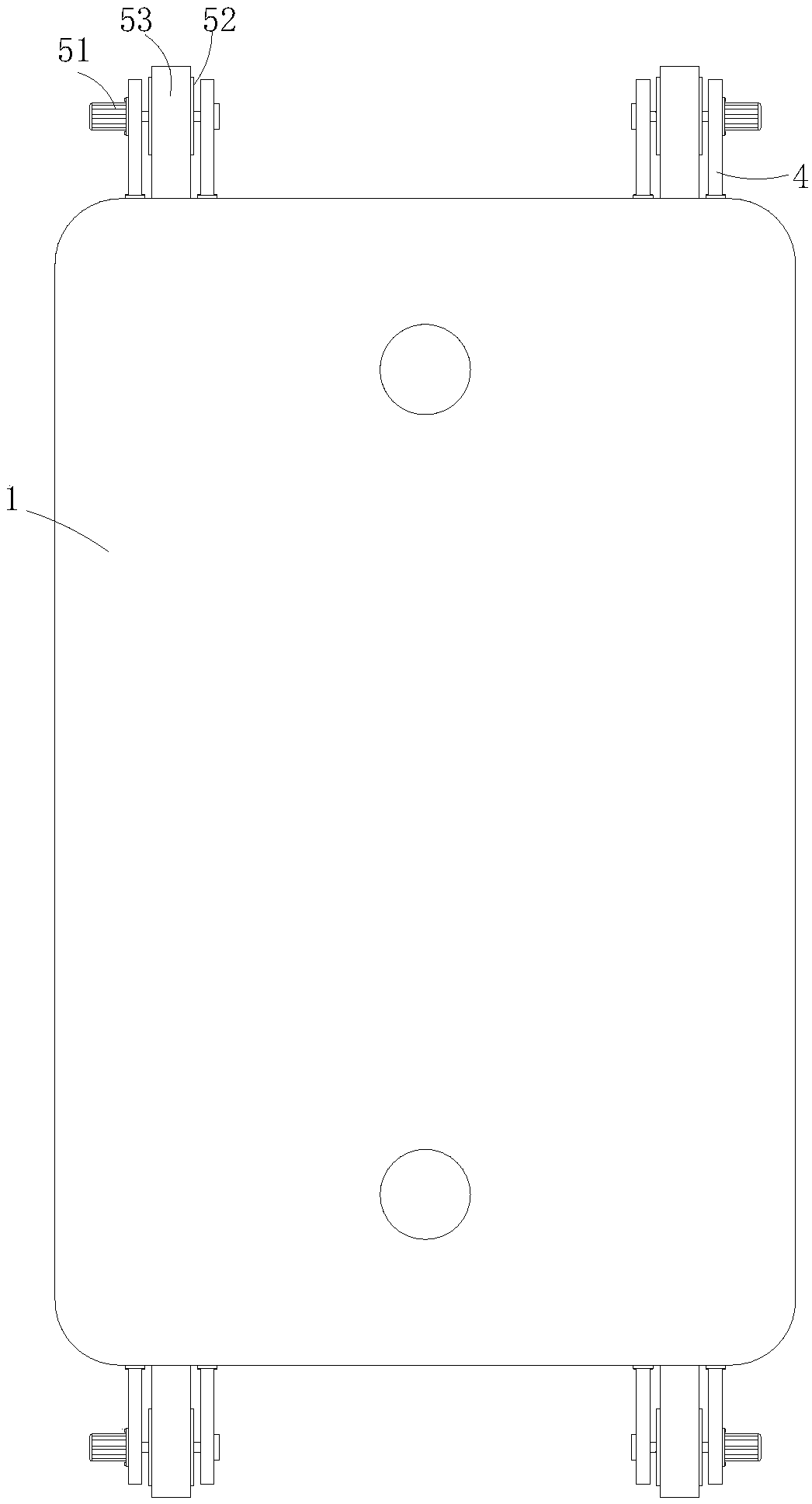

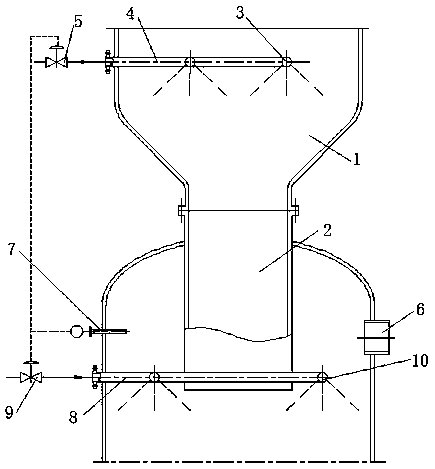

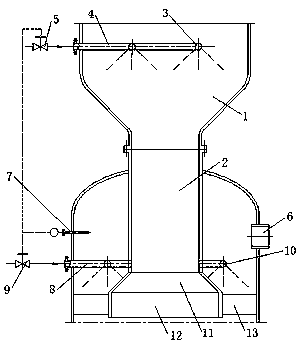

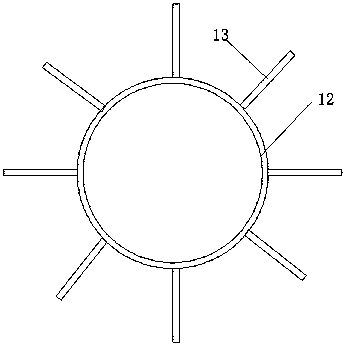

Fixed bed slag gasification furnace material distributing temperature controlling device

The invention relates to a gasification furnace, and more specifically relates to a fixed bed slag gasification furnace material distributing temperature controlling device. The fixed bed slag gasification furnace material distributing temperature controlling device is arranged on a gasification furnace, and comprises a buffer cabinet (1); the buffer cabinet (1) is arranged above a gasification furnace material inlet (2); the upper part of the buffer cabinet (1) is provided with an opening, the lower part is communicated with a gasification furnace material inlet (2); the upper part of the buffer cabinet (1) is provided with a material inlet spray head (3); the material inlet spray head (3) is communicated with a flowing raw material inlet pipe (4); the flowing raw material inlet pipe (4)is provided with a material introduction adjusting valve (5). The fixed bed slag gasification furnace material distributing temperature controlling device is capable of mixing raw materials introducedinto the gasification furnace to be more uniform, and realizing in time regulation, so that stable temperature control of the upper part of the gasification furnace and product gas is realized.

Owner:云南煤化集团工程技术有限公司 +1

Rolling mill guide and guard device

InactiveCN104399761AUniform cooling and coolingAvoid stuck phenomenonGuiding/positioning/aligning arrangementsLinear motionStrip mill

The invention discloses a rolling mill guide and guard device. The rolling mill guide and guard device comprises a guide and guard body, and a base; a spindle is fixed in the center at the lower end of the guide and guard body; the spindle is provided with a bearing; the bearing is fixed on a slide block; the base is provided with a sliding chute matching with the slide block; the guide and guard body is provided with a water passage; one end of the water passage is provided with a water inlet port; the other end thereof is provided with a water outlet port at the lower end of the guide and guard body. The guide and guard body is provided with the water passage, and the water passage is communicated with two water spraying ports, thereby rollers can be uniformly cooled, thus preventing the rollers from being jammed due to the excessive temperature; meanwhile, the guide and guard body is installed on the sliding chute, thereby providing convenience for the linear motion as well as rotating.

Owner:LIUZHOU RIP MACHINERY EQUIP

Mold with external cooling device

The invention discloses a mold with an external cooling device, and belongs to the technical field of mold cooling assistance. The mold comprises a mold body, the mold body comprises an upper mold, and the upper mold is connected with a lower mold. The upper mold communicates with an upper inner cooling mechanism, the lower mold communicates with a lower inner cooling mechanism, and the mold body is connected with a rotating device. The rotating device comprises a base, a power mechanism is arranged at one end of the base, the power mechanism is connected with a transmission mechanism, the transmission mechanism is connected with a clamping mechanism, and the clamping mechanism is connected with the mold body. An external cooling mechanism is arranged above the mold body. The mold is creatively designed in a rotating manner, the outer portion of the mold can be evenly cooled, then it is guaranteed that molten metal in a cavity is evenly cooled, the quality of a final product is improved, the rejection rate is reduced, and the benefits of enterprises is prevented from being influenced.

Owner:山东泰和能源股份有限公司

A steam turbine condenser

ActiveCN108253811BReduce operating costsReduce investmentSteam/vapor condensersHeat exchanger casingsWater flowEngineering

Owner:DONGFANG TURBINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com