Rolling mill guide and guard device

A technology of guide device and rolling mill, applied in the direction of guide/positioning/alignment device, etc., can solve the problems of inconvenient maintenance, cumbersome guide and guard assembly, uneven cooling of rollers, etc., to facilitate linear movement and avoid excessive temperature of rollers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

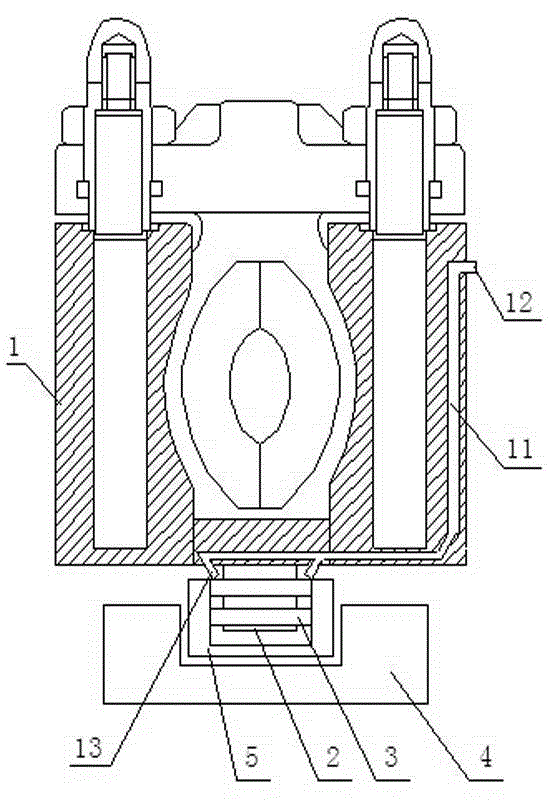

[0011] Such as figure 1 The rolling mill guide device shown includes a guide body 1, a rotating shaft 2 is arranged on the guiding body 1, and two bearings 3 distributed up and down are arranged on the rotating shaft 2, and the rollers are rotatably connected to the rotating shaft 2 through the bearings 3. superior.

[0012] The guide body 1 is provided with a water inlet 12, the water pipe is connected to the water inlet 12 through a quick connector, the guide body 1 is provided with a water channel 11 through the water inlet 12, and the guide body 1 is provided with two upper and lower water jets along the direction of the rotating shaft 13. The water spouts 13 communicate with the water channels 11 respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com